A device including a back side illuminated image sensor and a manufacture method of the image sensor

A technology of image sensing and manufacturing method, which is applied to electrical components, radiation control devices, electrical solid devices, etc., can solve the problems of crosstalk interference, insufficient isolation, and a large number of occurrences, and achieve the effect of reducing crosstalk interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following disclosure provides many different embodiments or examples for implementing different features of the present invention. The specific examples of elements and arrangements described below are used to simplify the disclosure, which are for illustration only, and are not intended to limit the disclosure. In addition, in the following description, a first feature is formed on or on a second feature may include embodiments in which the first and second features are in direct contact, and may also include an additional feature formed between the first and second features For example, the first and second features may not be in direct contact. Various features can be arbitrarily drawn in different sizes to achieve the purpose of conciseness and clarity.

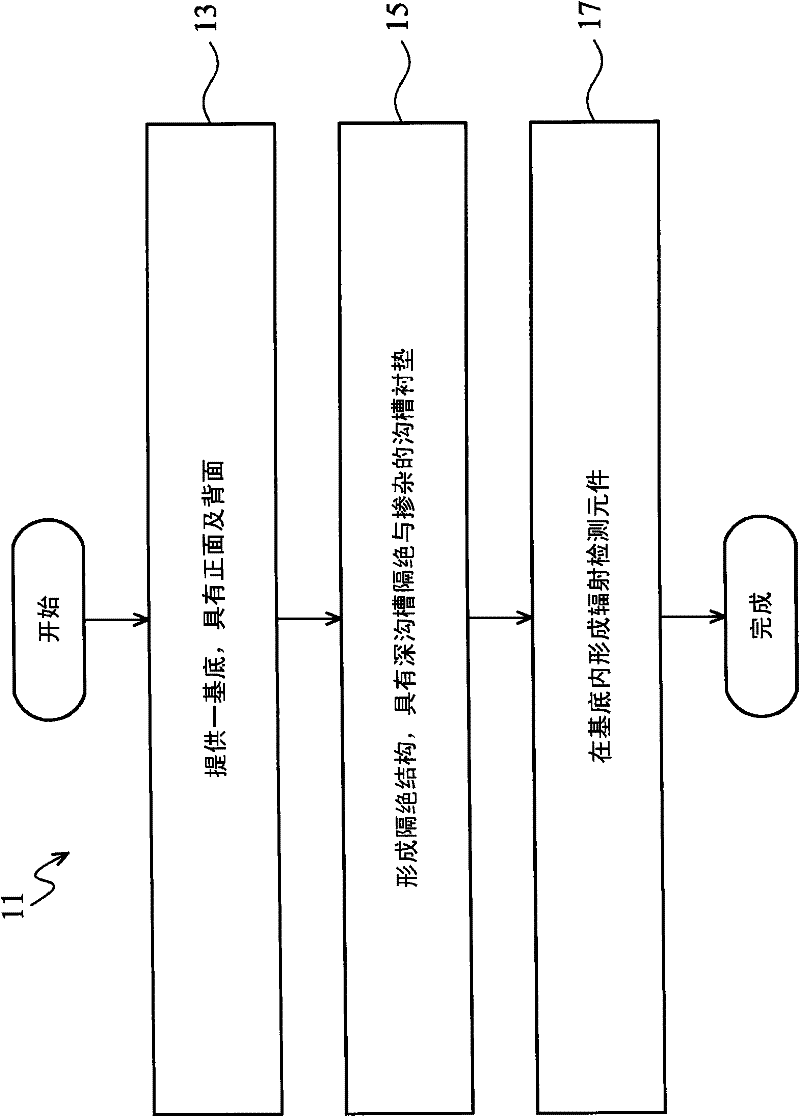

[0032] figure 1 A flowchart illustrating a method 11 of fabricating a backside illuminated (BSI) image sensing device in accordance with various concepts disclosed herein. refer to figure 1 , method 11 begin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com