Housing for axial flow threshing cylinder

A threshing drum and axial flow technology, which is applied in the field of agricultural machinery, can solve the problems of not being able to harvest easy-to-thresh crops, easy-to-wrap grains, and easy-to-thresh crops that are easy to run away, so as to expand the variety and scope, reduce resistance, and solve the problems of easy-to-thresh crops. The effect of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

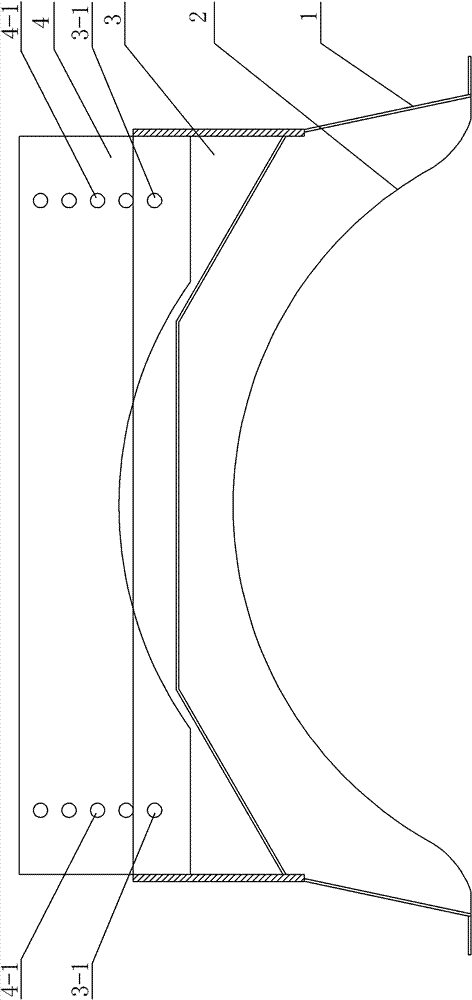

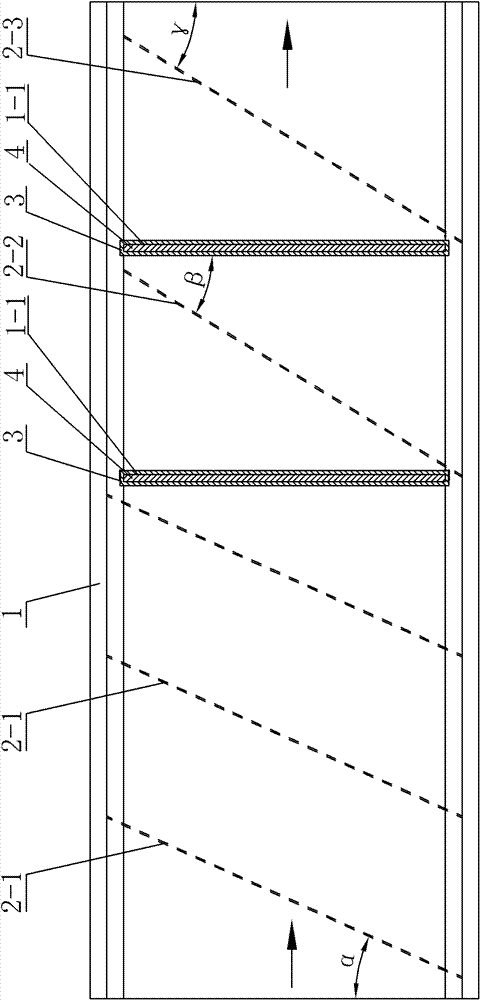

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. A casing for an axial-flow threshing drum in this embodiment includes a housing 1 and a guide vane set 2. The guide vane set 2 includes a second guide vane 2-2, a third guide vane 2 -3 and a plurality of first guide vanes 2-1, which also includes two plug-in plates 3 and two speed-limiting baffles 4, the housing 1 is provided with an end face parallel to the housing 1 along the width direction of the housing Two parallel openings 1-1, on the inner wall of the housing 1 between the feeding port and the opening 1-1 near the feeding port side, there are a plurality of first ones evenly distributed and parallel along the length direction of the housing 1. Guide vane 2-1, a second guide vane 2-2 is fixedly attached to the inner wall of housing 1 between the opening 1-1 on the side of the feed opening and the opening 1-1 on the side of the crop outlet, A third guide vane 2-3 is affixe...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 To describe this embodiment, the included angle α between the side surface of each first guide vane 2 - 1 in the longitudinal direction and the end surface of the housing 1 in this embodiment is 35° to 45°. Such setting is beneficial to the threshing of crops and meets the design requirements and actual work needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 To describe this embodiment, the second guide vane 2-2 and the third guide vane 2-3 of this embodiment are arranged in parallel, and the angle β between the side surface of the second guide vane 2-2 in the longitudinal direction and the end surface of the housing 1 is The included angle γ between the side surface in the length direction of the third guide vane 2-3 and the end surface of the casing 1 is 20-35°. Such setting makes it easy to discharge easily entangled crops, reduces resistance, and meets design requirements and actual work needs. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com