Self-guide flow type core material and processing method thereof

A processing method and the technology of diversion core, which are applied in the field of self-guided core material and its processing, can solve the problems of waste of raw materials such as glue, poor surface quality of parts, and high glue content, so as to reduce the waste of glue , Improve production efficiency, use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

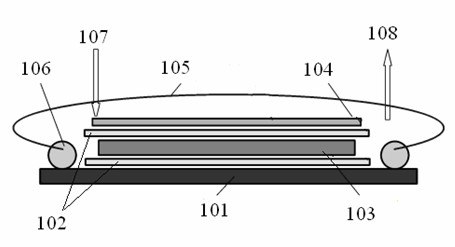

[0011] Below in conjunction with accompanying drawing, the present invention is described in detail, figure 1 It is a schematic diagram of the vacuum infusion of the core material using the processing method of the present invention. The whole infusion system is composed of a mold 101, a glass fiber 102, a sandwich material 103, a release cloth 104, a vacuum bag film 105, a sealant 106, an injection port 107 and an air extraction system. 108 composition, the diversion medium is removed during laying.

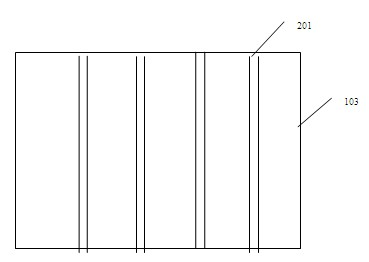

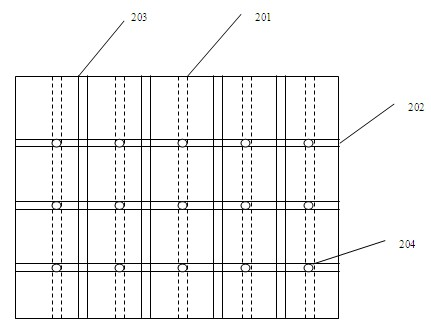

[0012] figure 2 , image 3 The upper surface and the lower surface of the core material 103 of the processing method of the present invention are described. The upper surface of the core material 103 is longitudinally cut grooves 201 at a certain interval, and the lower surface is horizontally cut grooves 201 at a certain interval and longitudinally added shallow grooves 203 . The depth of the groove is 1 / 2-4 / 5 of the thickness of the core material, and the width of the groo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap