Sealed compressor shell

A technology for hermetic compressors and compressor shells, which is applied in the field of compressor manufacturing, and can solve problems such as increased shell size and weight, reduced welding process at the bottom of the lower shell, unreasonable use of shell space, etc. , to achieve the effect of saving oil injection, reducing cost and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

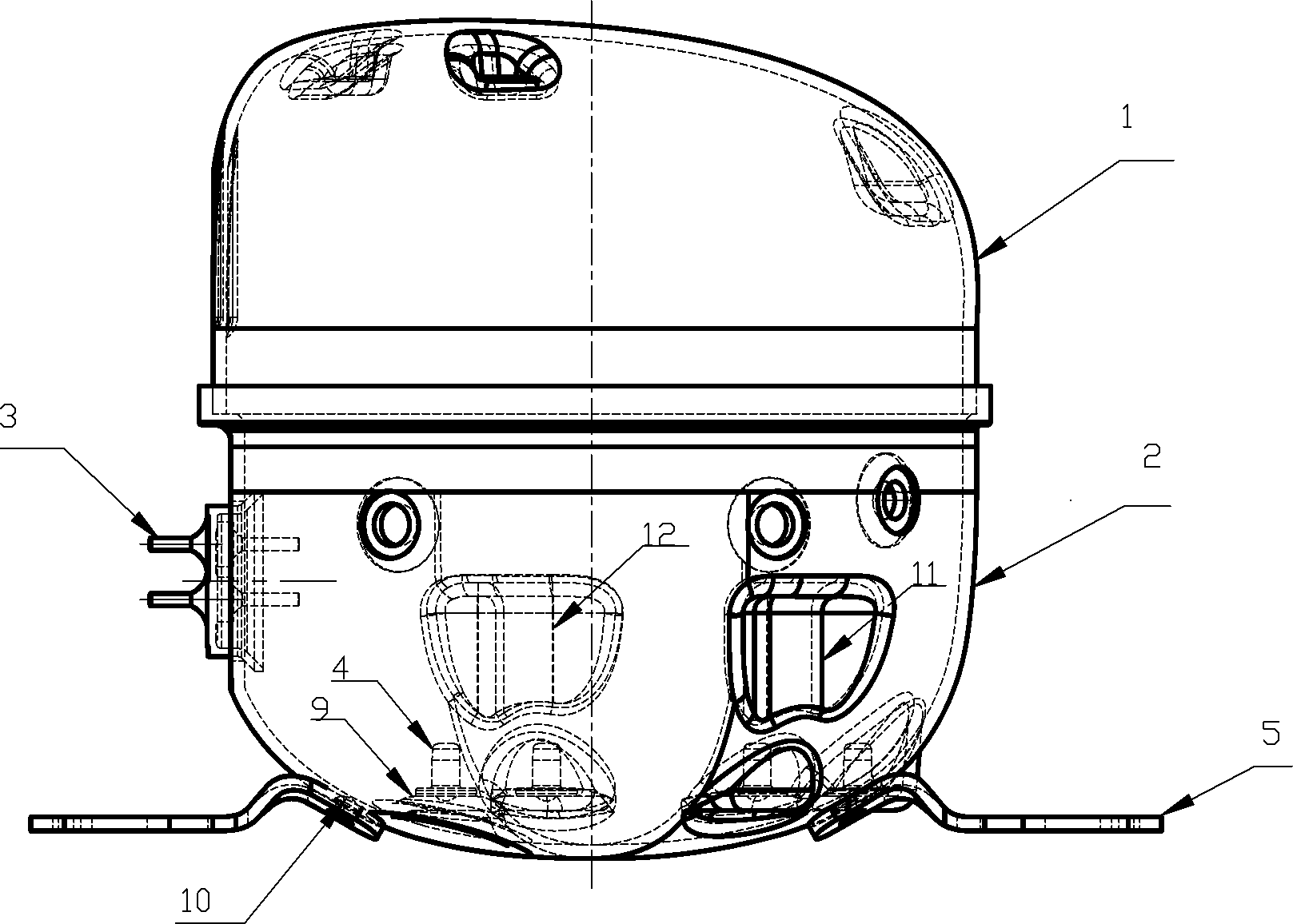

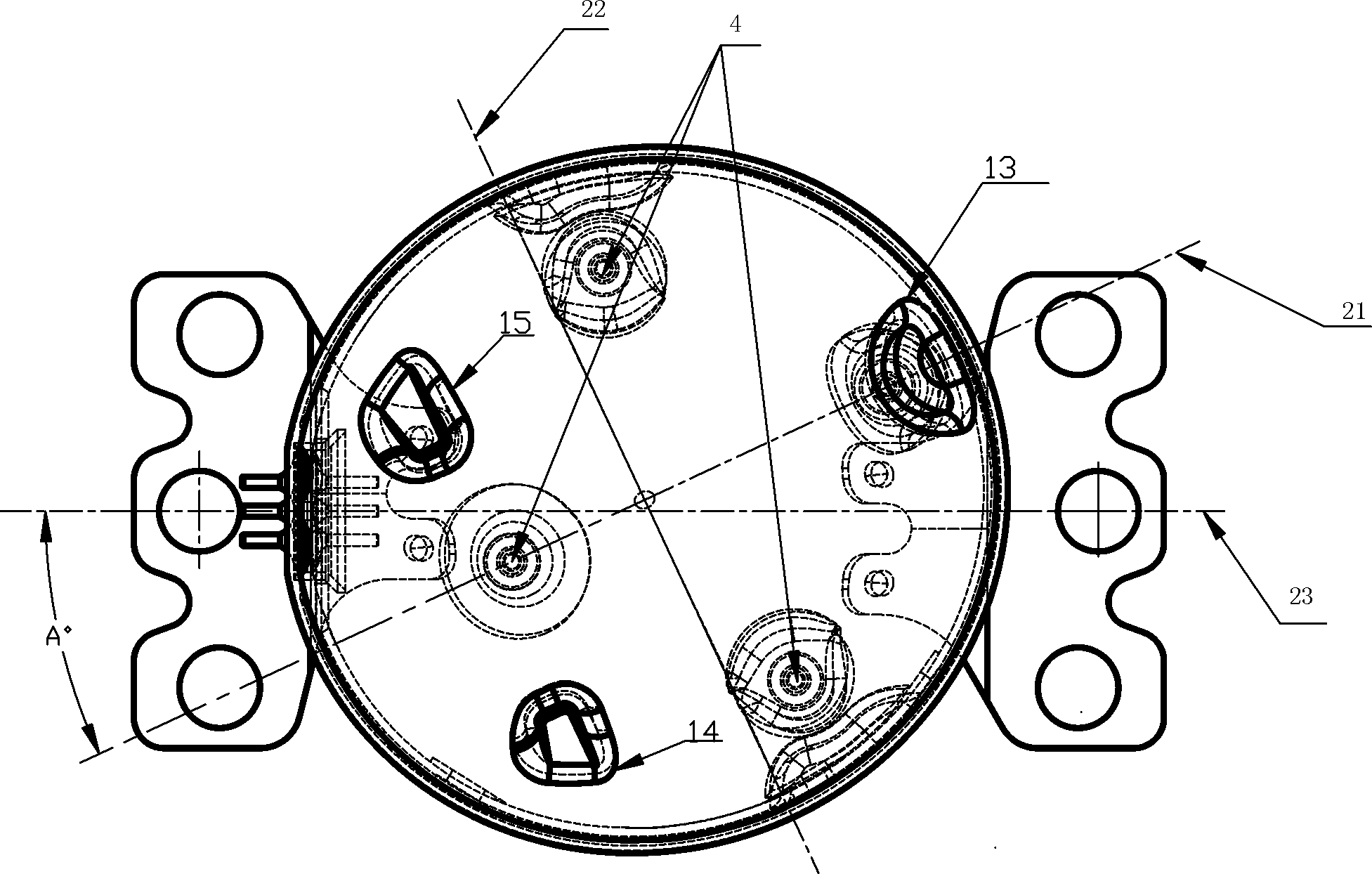

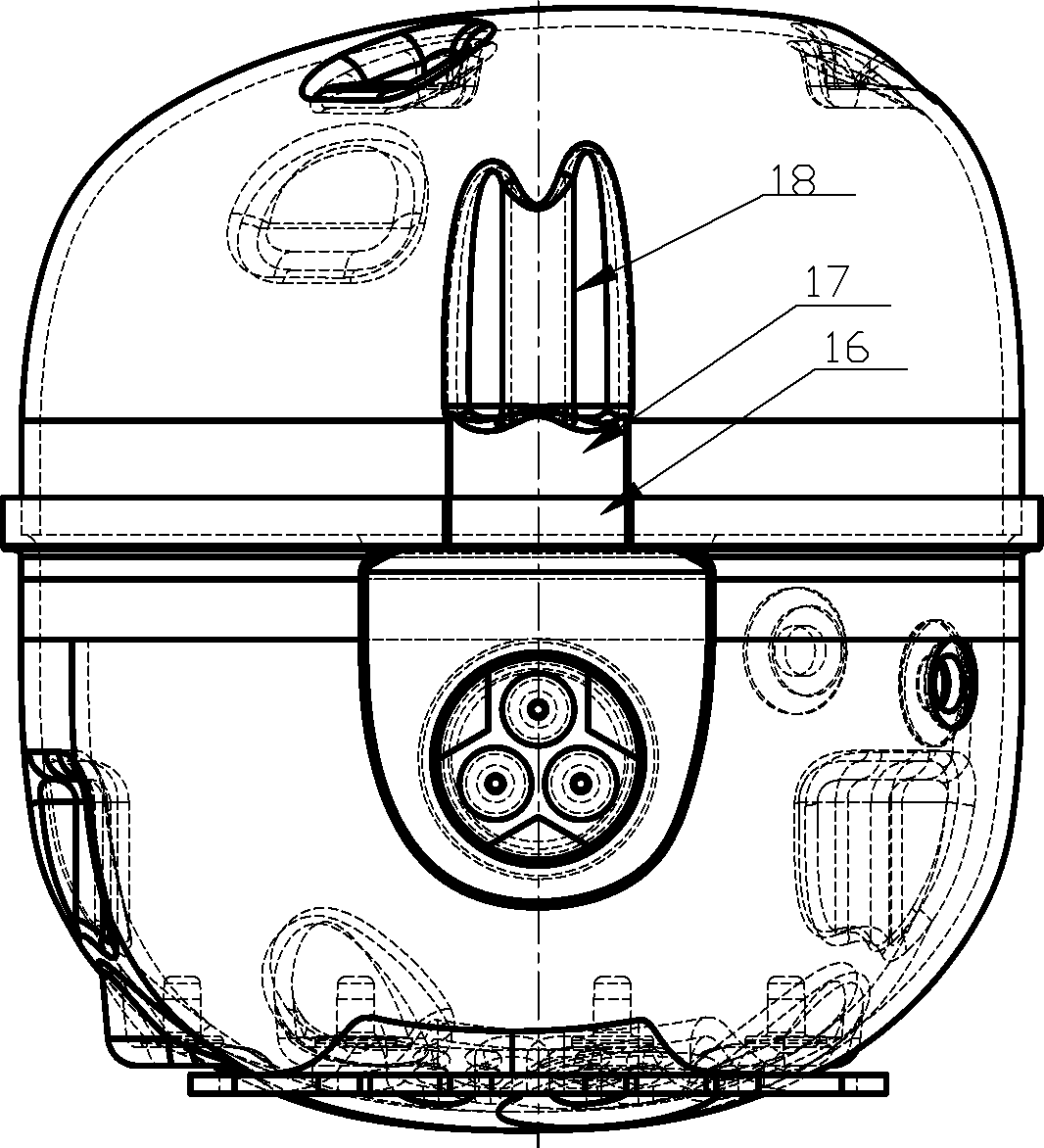

[0027] The following is attached Figure 1-5 The embodiment of the present invention is described further, but does not limit the present invention.

[0028] see Figure 1-5 The housing of the present invention is suitable for hermetic refrigeration compressors, especially small hermetic refrigeration compressors, and mainly includes a cylindrical upper cover 1 and a lower shell 2 that can be engaged with each other, and the horizontal section of the upper cover 1 and the lower shell 2 It is elliptical, and the elliptical major axis centerline 21 of the upper cover and the lower shell coincides, and similarly, the elliptical minor axis centerline 22 of the housing upper cover and the lower shell also coincides; the terminal 3 is arranged on the lower shell 2 And it is symmetrical with the center line 23 of the terminal hole; the top surface of the upper cover 1 is asymmetrical spherical shrinkage, and the terminal side and the front side are higher than the rear side; the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com