Device, circuit and method for detecting liquid level of nitric acid storage tank

A technology of liquid level detection and nitric acid, applied in the direction of buoy liquid level indicator, etc., can solve the problem of unsafe labor, and achieve the effect of less investment in hardware facilities, simple wiring, and meeting the needs of equipment control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

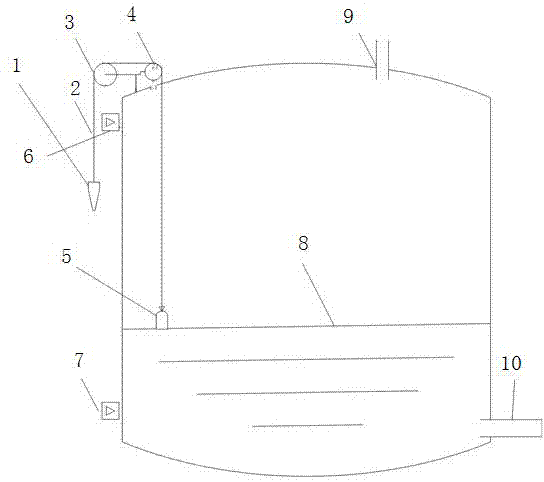

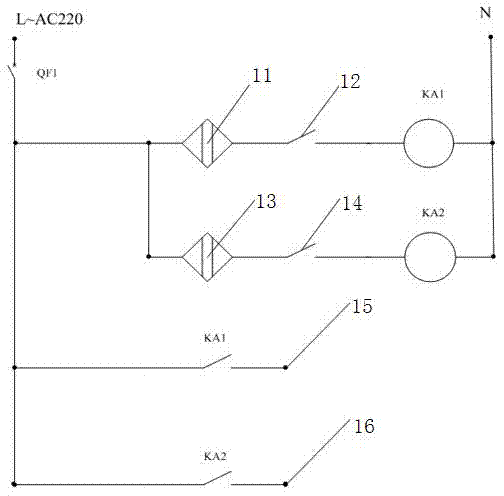

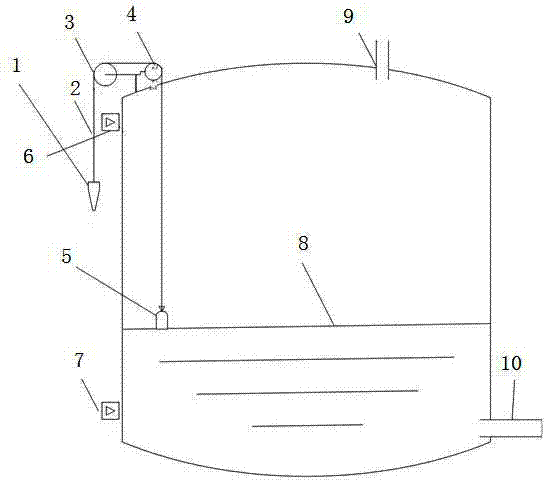

[0024] Combine below figure 1 and figure 2 , the present invention is further described:

[0025] Such as figure 1 As shown, a nitric acid storage tank liquid level detection device includes a nitric acid storage tank, a nitric acid storage tank inlet pipe 9 and a nitric acid storage tank outlet pipe 10, and a liquid level detection device is provided on the nitric acid storage tank. The liquid level detection device includes a metal balance weight 1, a stainless steel rope 2, a pulley component and a stainless steel liquid level float 5, the metal balance weight 1 is located outside the nitric acid storage tank, and the stainless steel liquid level float 5 floats on the nitric acid liquid surface 8, The metal balance weight 1 is connected with the stainless steel liquid level float 5 through a stainless steel rope 2 and a pulley.

[0026] The pulley includes a left pulley part 3 and a right pulley part 4, the left pulley part 3 and the right pulley part 4 are located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com