Small simulation device for testing spontaneous combustion period of coal

A technology for simulating device and spontaneous combustion of coal, which is applied in the fields of soil material testing and material inspection, which can solve the problems of unsatisfactory coal, low maximum temperature, heat flow, etc., and achieve good temperature protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the figures.

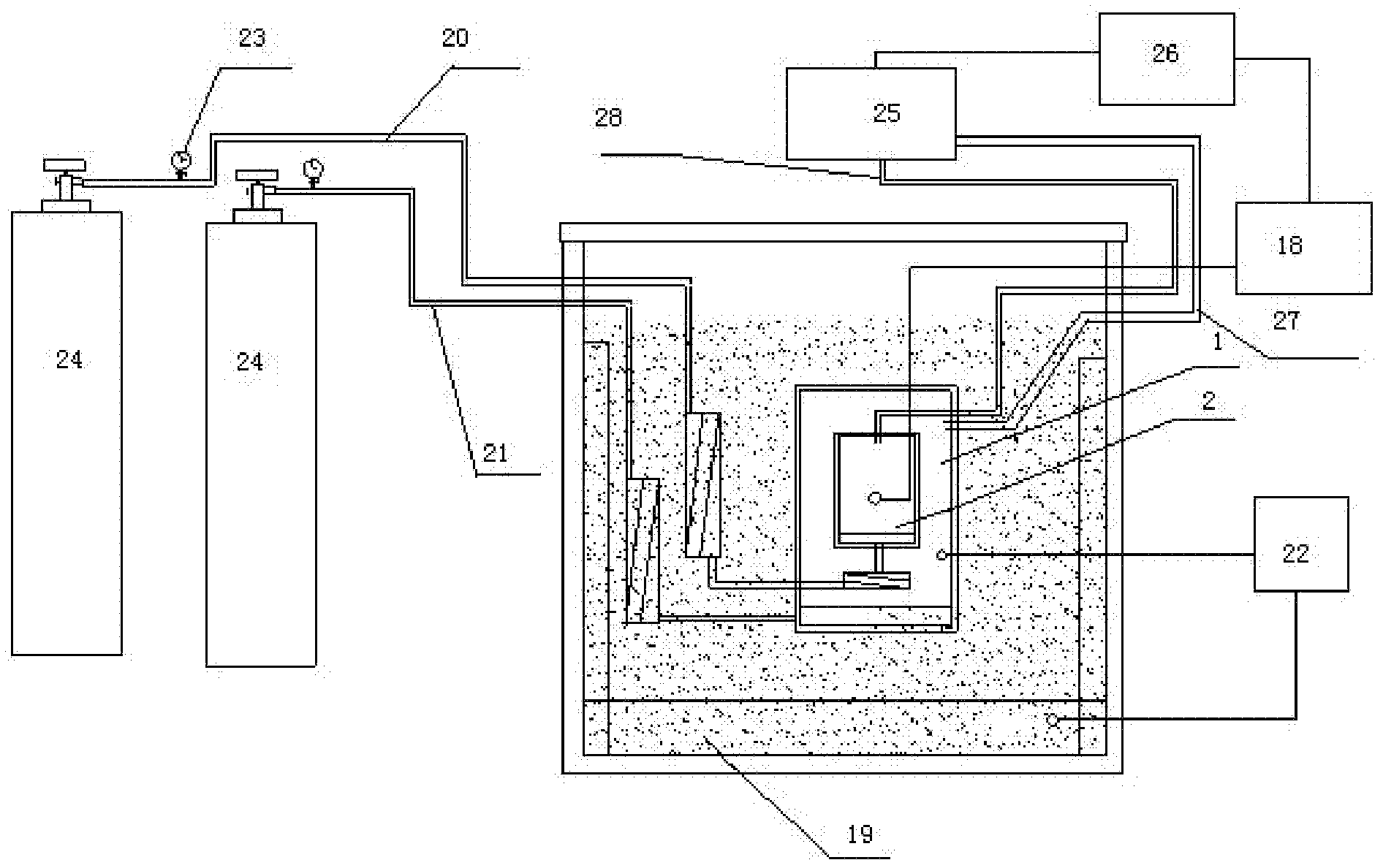

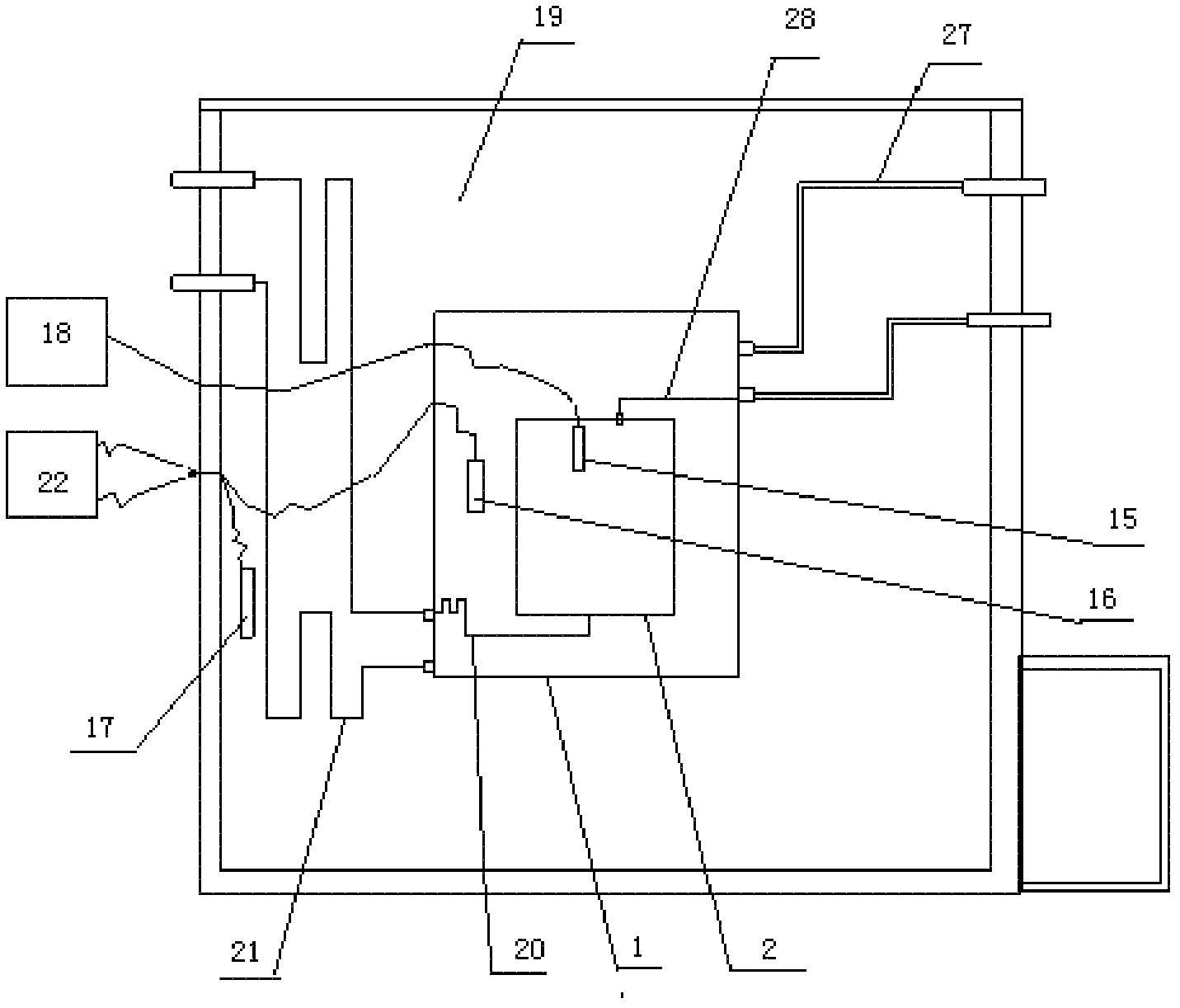

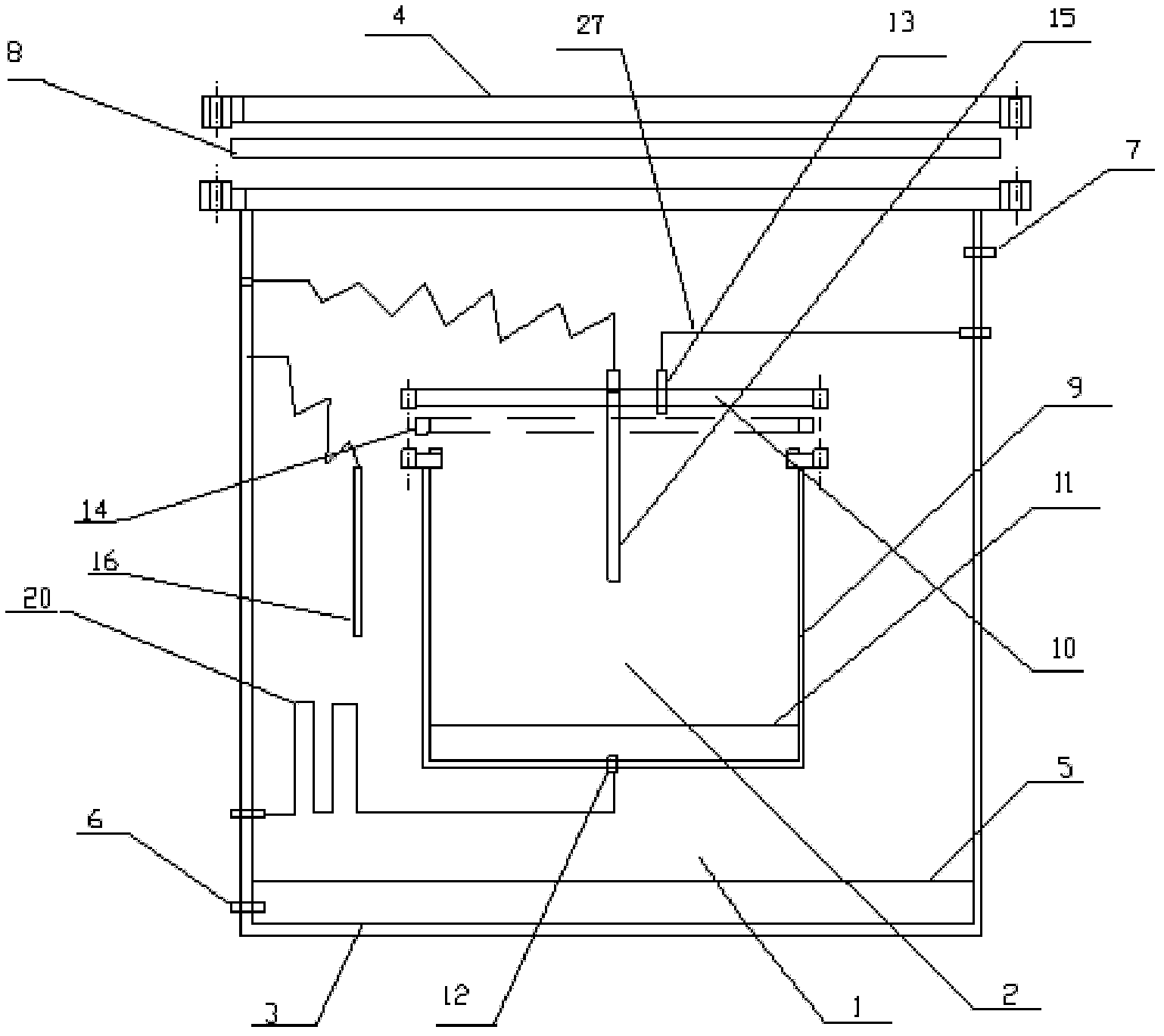

[0023] Such as figure 1 , figure 2 , image 3 As shown, the present invention tests a small-scale simulation device for spontaneous combustion of coal, and the simulation device consists of an external furnace 1, an internal furnace 2, a furnace body II 3, an external furnace flange cover 4, an external furnace iron grid 5, and an external furnace air intake nozzle 6 , outer furnace outlet gas nozzle 7, asbestos board 8, furnace body I9, inner furnace flange cover 10, inner furnace iron grid 11, inner furnace inlet gas nozzle 12, inner furnace outlet gas nozzle 13, sealing ring 14, inner furnace Temperature sensor 15, external furnace temperature sensor 16, sand bath temperature sensor 17, temperature data collector 18, sand bath device 19, internal furnace intake pipe 20, external furnace intake pipe 21, temperature controller 22, gas flow met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com