Detaching tool for big belt pulley

A technology for dismantling tools and large pulleys, which is applied in the manufacture of tools and hand-held tools, etc. It can solve problems such as deformation, female thread strain of large pulleys, and large destructiveness of crushers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

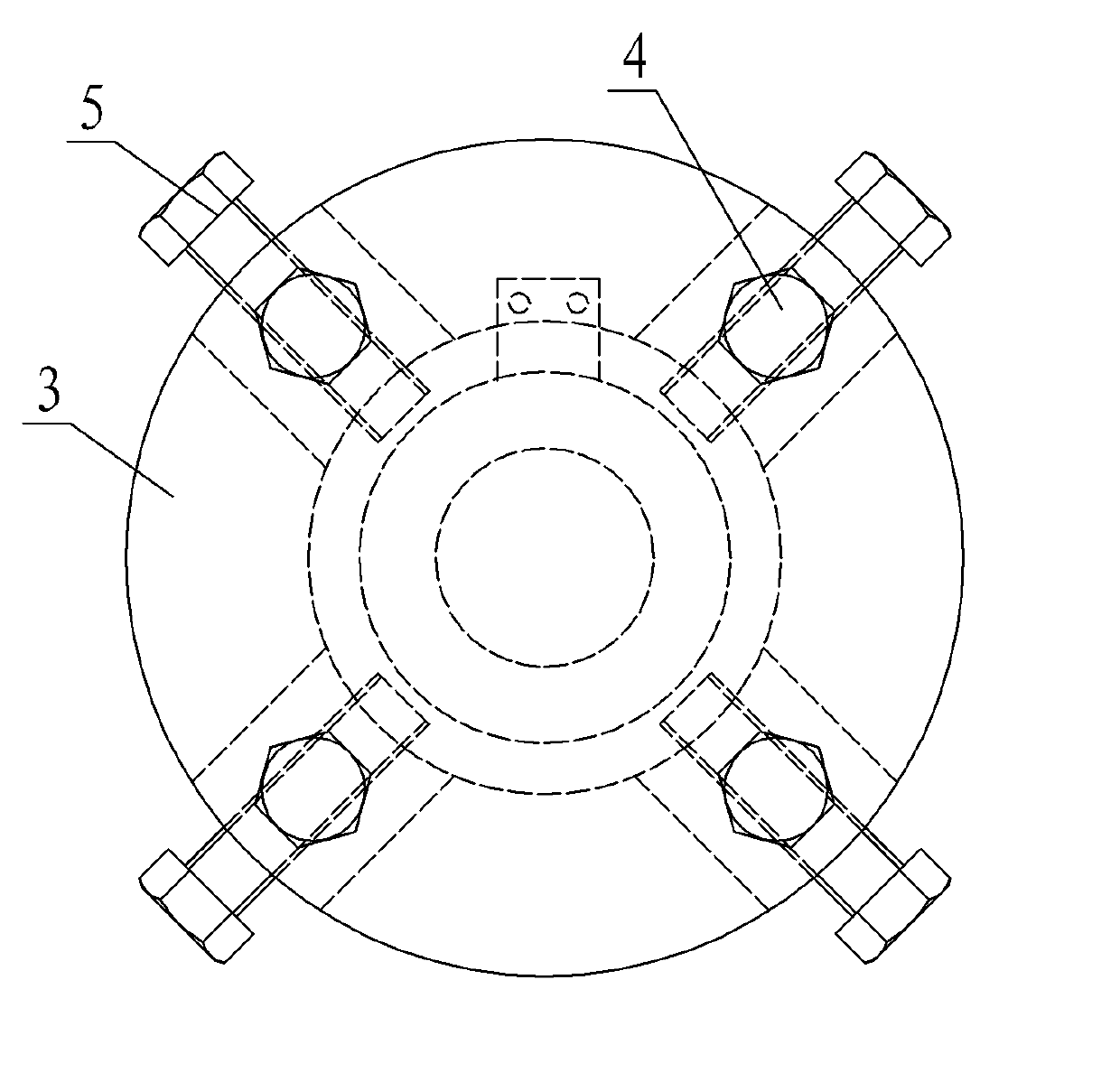

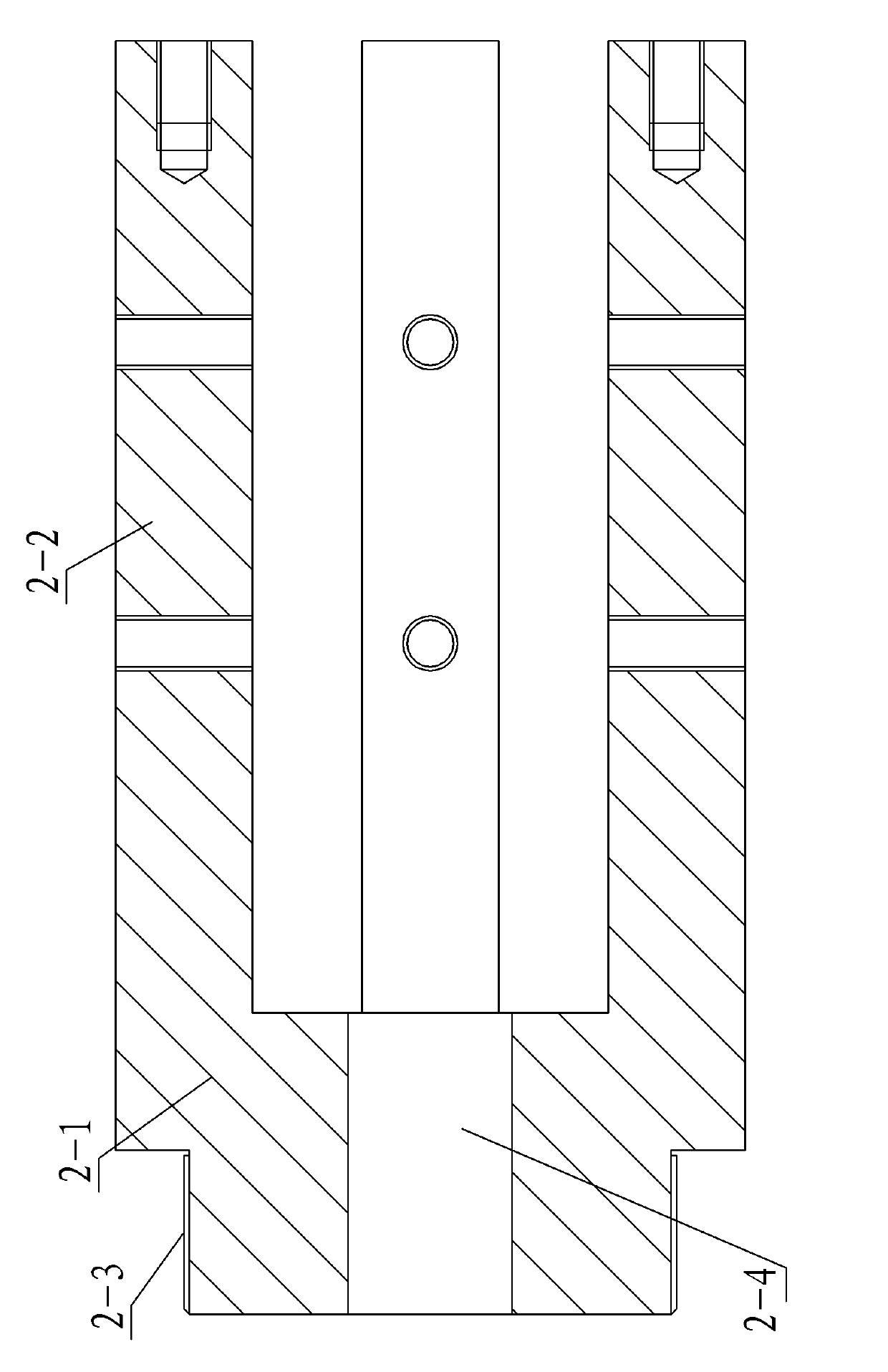

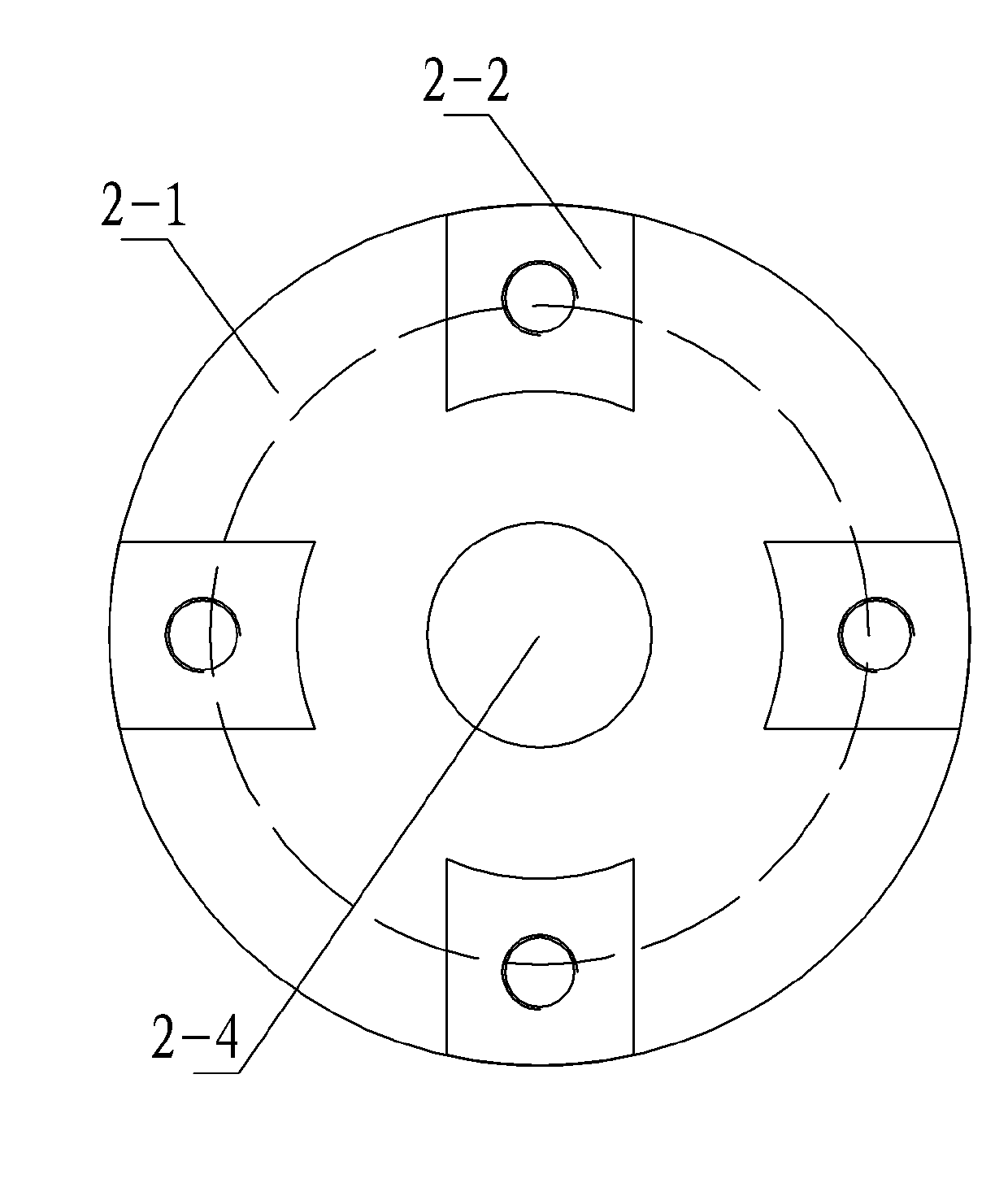

[0016] Example: see figure 1 , a large pulley removal tool in the figure, including a guide sleeve, a hydraulic cylinder, and an end cover. The guide sleeve includes a front disc body and several support rods connected to the disc body along the circumference. The end cover Installed on the tail of the support rod parallel to and facing the disc body, the hydraulic cylinder is placed between the disc body and the end cover, and is located inside several support rods, and the front end of the disc body is provided with a protruding In the threaded section, a through hole is provided in the middle of the disc body, and the piston rod of the hydraulic cylinder expands and contracts in the through hole. Each support rod is provided with a set bolt facing the internal hydraulic cylinder. The end cover is installed on the tail of the support rod through fixing bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com