Thread lock

A technology of thread lock and lock shell, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of flying out of the bottom plate or skirt plate, disappearance of pre-tightening force, loosening of T-shaped screw 101, etc., so as to achieve easy maintenance and replacement. , the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

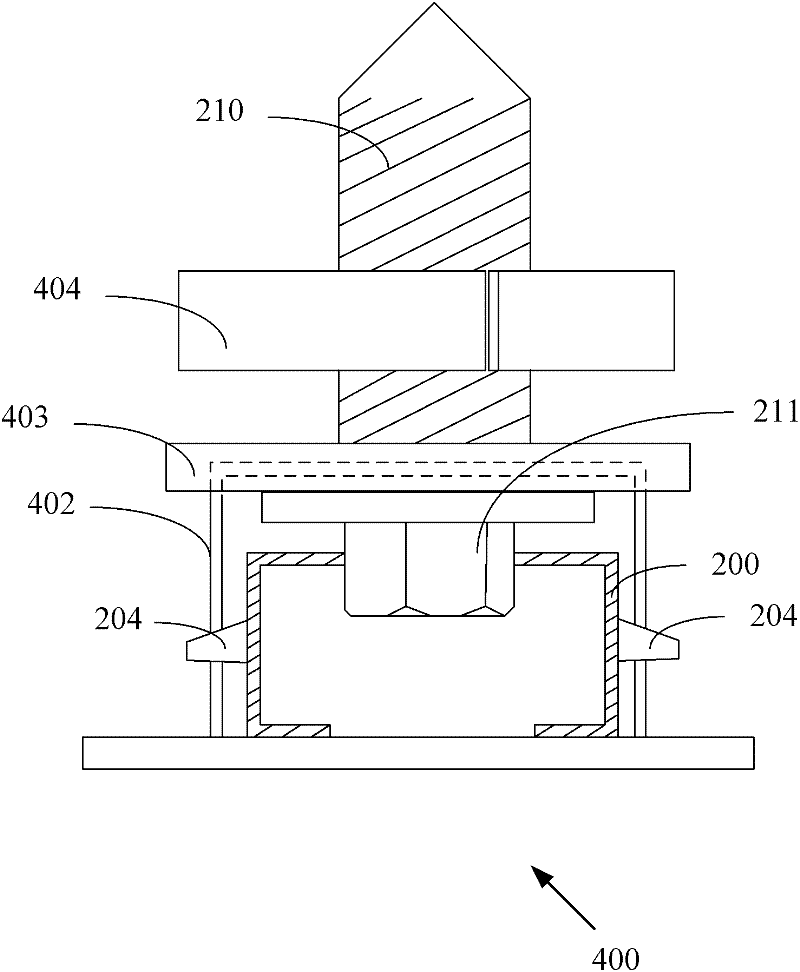

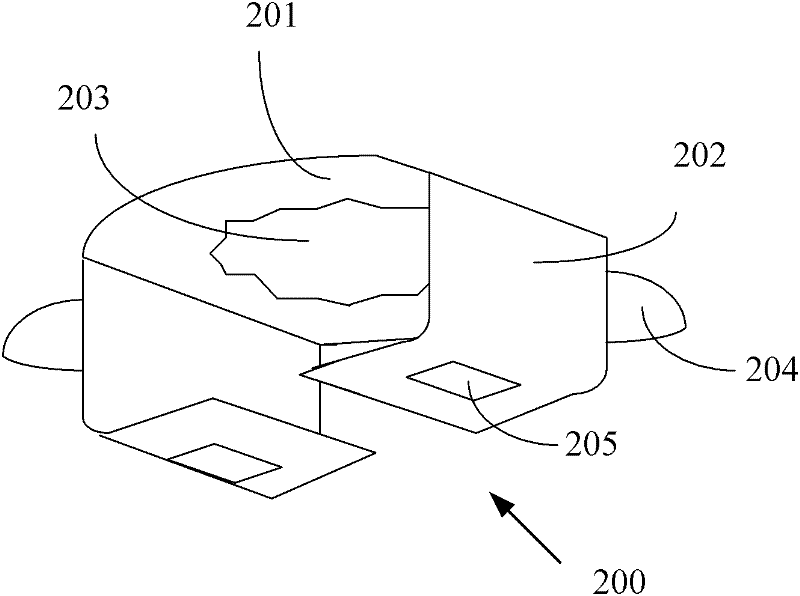

[0032] like Figure 2A Shown is a schematic structural view of the thread lock according to the first embodiment. The thread lock 400 comprises: a screw 210 with a polygonal head 211, a lock case 402, a locking part 403, and a nut 404, and the screw 210 passes through the lock case 402, the locking part 403 and the nut 404 in turn, so that the polygonal head 211 is positioned at Inside the lock case 402 , at least one locking slot (not shown in the figure) is provided on the side wall of the lock case 402 , and the lock case 402 is also provided with a holding part 200 . combine Figure 2B As shown, the clamping component 200 has a top plate 201 and at least one side plate 202 connected to the top plate 201 . A non-return hole 203 is opened on the top plate 201, and the non-return hole 203 is used to clamp the polygonal head 211. There is at least one protrusion 204 on the side plate 202, and the protrusion 204 is located in the slot, and slides and fits with the slot. When...

Embodiment 2

[0040] The second embodiment further improves the thread lock of the first embodiment. like Figure 4 As shown, it is an exploded view of the thread lock 500 according to the second embodiment, which shows the locking groove 410 on the lock case 402 . like Figure 5 As shown, it is a schematic structural diagram of the thread lock 500 according to the second embodiment. The thread lock 500 also includes a flat washer 501 and a wave washer 502 sleeved on the screw rod 210 , the flat washer 501 and the wave washer 502 are located in the lock housing 402 , and the flat washer 501 is located above the wave washer 502 . Other structures are consistent with those in Embodiment 1.

[0041] According to the thread lock 500 of the second example, the flat washer 501 and the wave washer 502 can increase the pre-tightening force of the screw 210 and the nut 404 through the deformation and friction caused by the screw 210, and improve the ability to prevent loosening and loosening.

...

Embodiment 3

[0045] like Figure 6A As shown, it is a schematic view viewed from the R-R direction of the thread lock 500 of the second embodiment. The clamping part 200 and the lock case 402 are respectively provided with looseness identification marks 601A and 601B. When the screw 210 is tightened, the looseness identification mark 601A of the clamping part 200 and the looseness identification mark 601B of the lock case 402 are located on the same straight line.

[0046] When the screw 210 rotates, that is, when the screw 210 becomes loose, the clamping part 200 will rotate in the lock housing 402. At this time, the loose identification marks 601A and 601B are no longer located on the same straight line, such as Figure 6B shown. At this time, the staff can judge whether the screw rod 210 is loose according to the states of 601A and 601B, and can carry out inspection and maintenance in time to further ensure the tight connection between the bottom plate and the vehicle body.

[0047] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com