Manufacture method for inner composite pipe

A manufacturing method and internal compounding technology, applied in the field of machinery, can solve the problem of easy existence of micro gap between the base pipe and the inner pipe, and achieve the effect of reliable technical effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

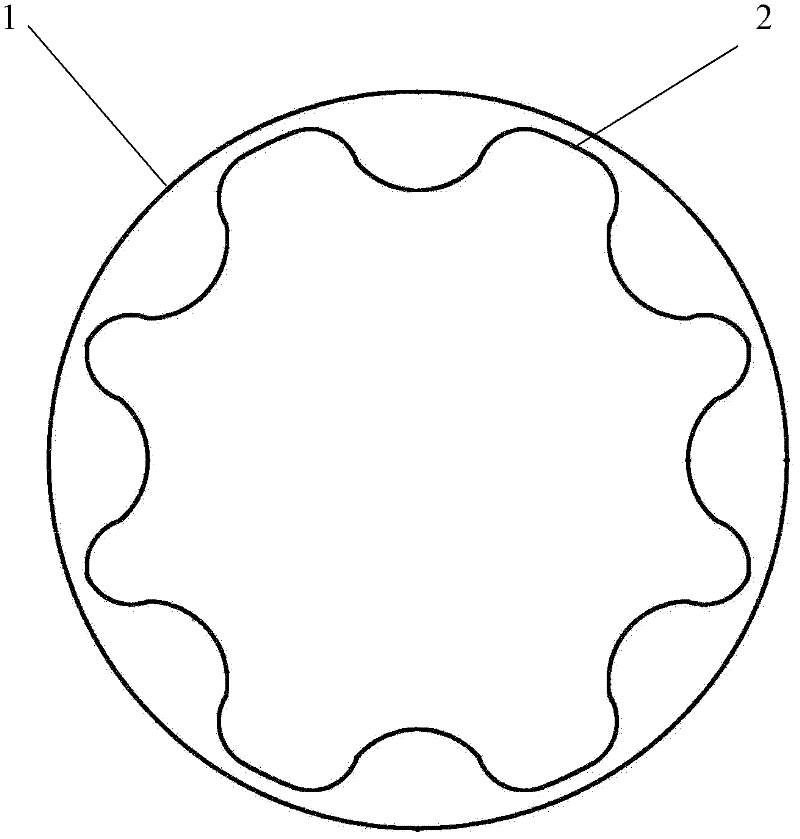

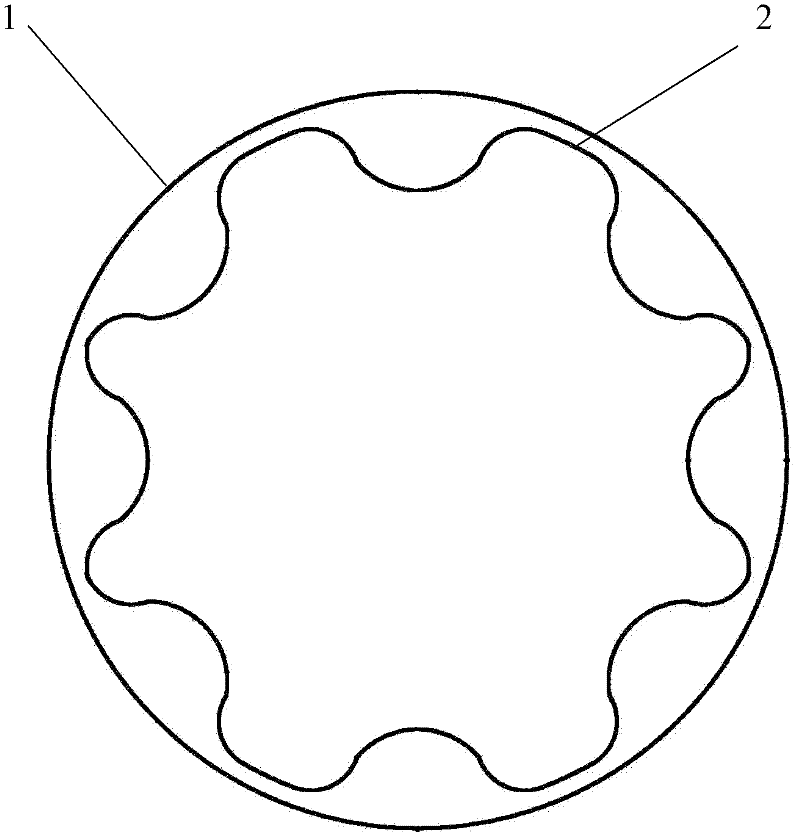

[0015] Such as figure 1 As shown, the manufacturing method of the inner composite pipe of the present invention includes a process of combining the inner pipe 1 with the base pipe 2, wherein, in the process of combining the inner pipe 1 with the base pipe 2, firstly, a mechanical tool is used to Processing and deforming the tube wall of the inner tube 1 and reducing the outer diameter of the inner tube 1, then putting the inner tube 1 into the base tube 2, and then applying Hydraulic pressure or mechanical pressure expands the inner tube 1 into a cylindrical tubular shape.

[0016] Further, after the inner tube 1 is put into the base tube 2, hydraulic pressure is first applied from the lumen of the inner tube 1 to the inner wall of the inner tube 1, and then mechanical pressure is applied from the lumen of the inner tube 1 to the inner wall of the inner tube 1 , or first apply mechanical pressure from the lumen of the inner tube 1 to the inner wall of the inner tube 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com