Prefabricated upright post and bearing platform assembled structure and assembling and positioning process thereof

A prefabricated assembly and column technology, which is used in infrastructure engineering, erection/assembly of bridges, roads, etc., can solve the problems of difficult positioning of bridge piers and the lack of detailed introduction of assembly construction positioning technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

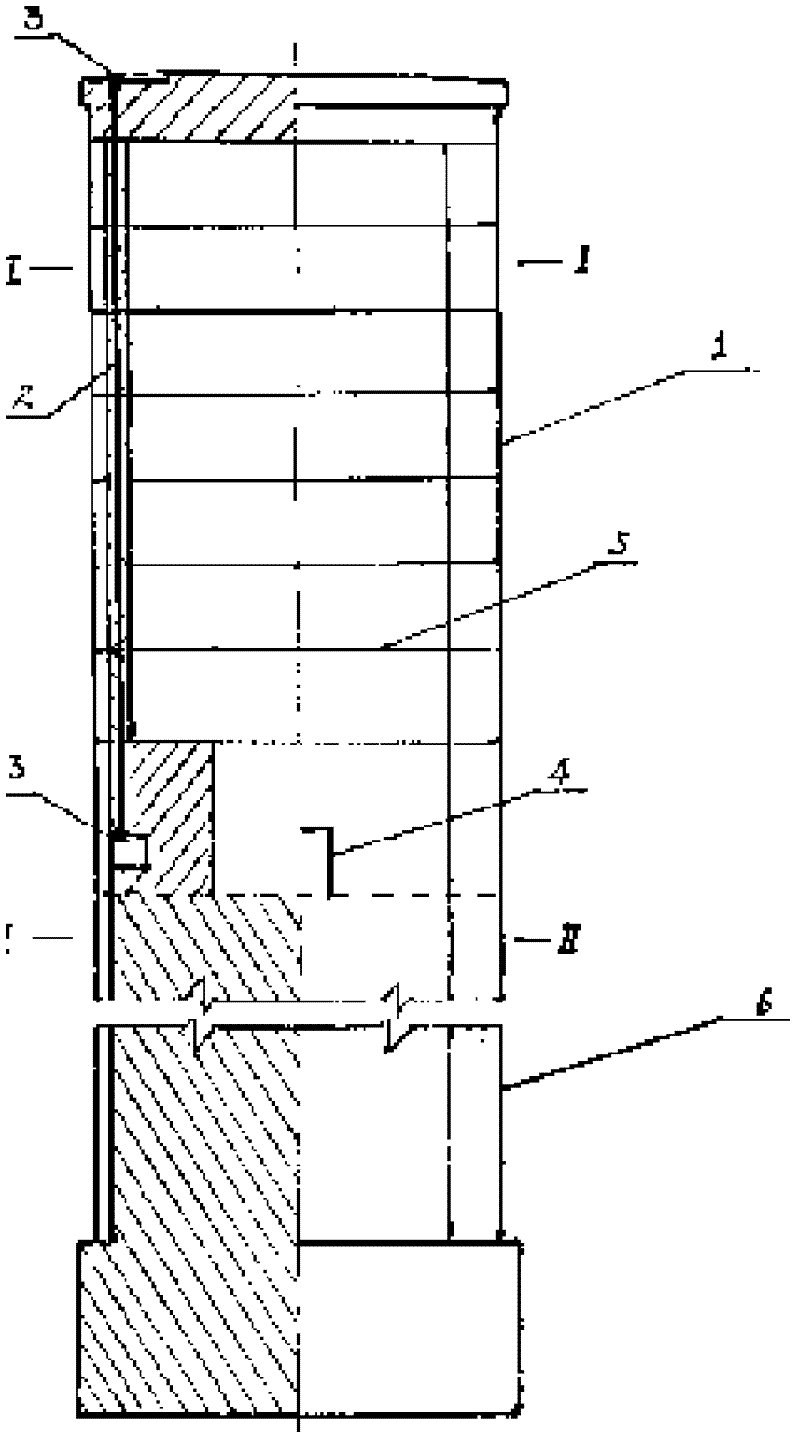

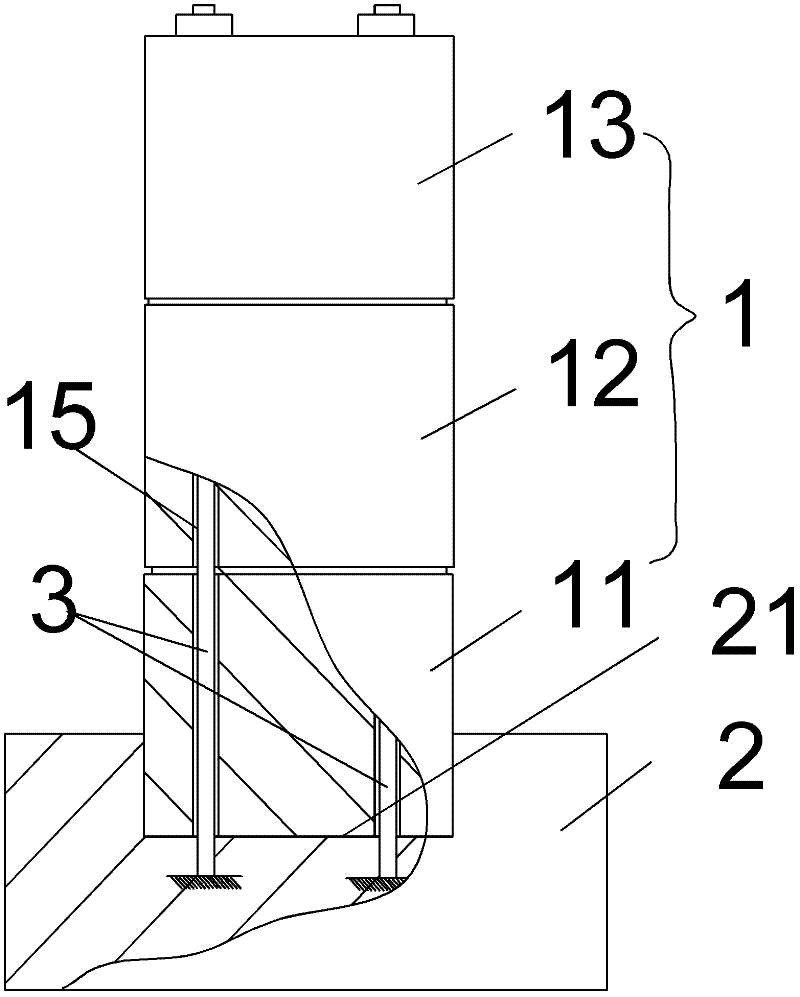

[0030] Such as image 3 As shown, a specific embodiment of the prefabricated assembled column bearing platform structure of the present invention includes two parts of the column 1 and the bearing platform 2, which are fixedly connected to form the column bearing platform structure.

[0031] A connecting plane 21 is formed on the surface where the bearing platform 2 and the column 1 are fixedly connected. Preferably, the connecting plane 21 is lower than the upper plane of the platform 2.

[0032] Of course, in other embodiments, the connecting plane 21 can also be flush with the upper plane of the platform 2 or higher.

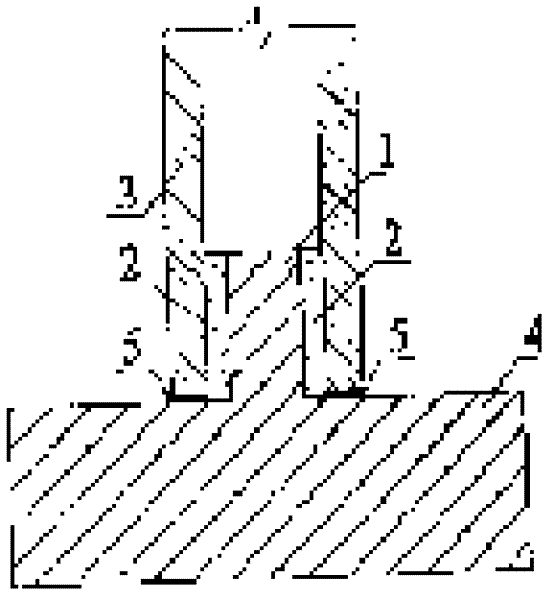

[0033] A pre-stressed component 3 is fixedly arranged on the connecting plane 21. In this embodiment, the prestressed component 3 is a thick threaded steel bar, which is anchored in the connecting plane 21 and erected in a direction away from the connecting plane 21.

[0034] The column 1 is assembled by several prefabricated column segments 11, 12, 13 and so on. ...

Embodiment 2

[0042] The structure of this embodiment is basically the same as that of the foregoing embodiment, except that the prestressed component 3 is a prestressed steel strand, which is anchored in the connection plane 21 of the bearing platform 2.

[0043] In addition, in this embodiment, the bearing platform 2 and the prefabricated column section 11, and the prefabricated column sections 11, 12, 13 are fixedly connected by cast-in-place concrete.

Embodiment 3

[0045] The assembly and positioning process of the prefabricated assembled column cap structure of the present invention is used to realize the accurate positioning between the prefabricated column segments and the caps and between the prefabricated column segments during the installation process of the prefabricated assembled column cap structure , Including the following steps:

[0046] Step one, refer to image 3 As shown, a pre-stressed component 3 is fixedly arranged in the connecting plane 21 of the bearing platform 2.

[0047] In different embodiments, the prestressed component 3 can be thick rebar or prestressed steel strand. The special feature of the present invention is that the prestressed component 3 also doubles as a positioning component.

[0048] Step two: hoist a prefabricated column section 11 on the connecting plane 21.

[0049] Among them, during the hoisting construction process, it is necessary to ensure that the prestressed component 3 is inserted in the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com