Method for inhibiting back cavitation of blade of mixed-flow water turbine

A technology of the back of the blade and the water turbine, which is used in the testing of machine/structural components, fluid dynamics testing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

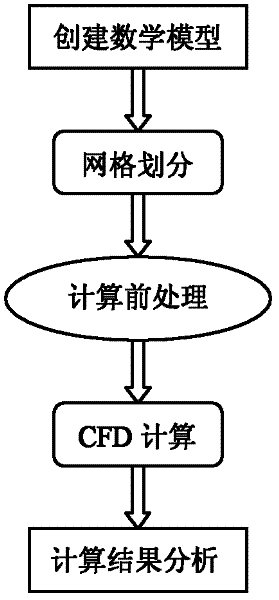

Method used

Image

Examples

Embodiment Construction

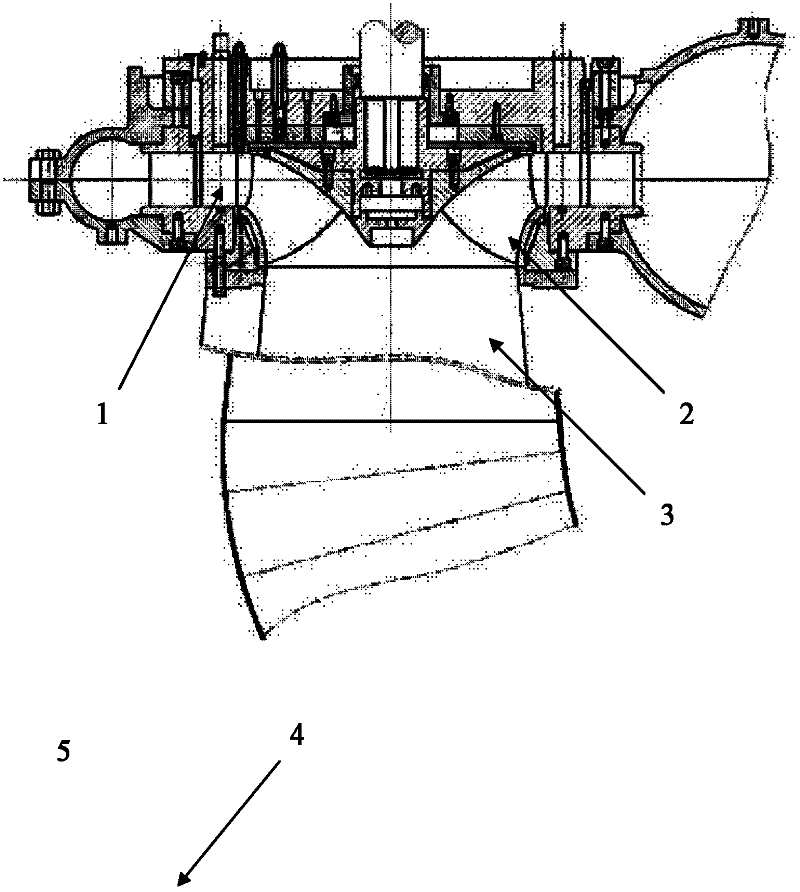

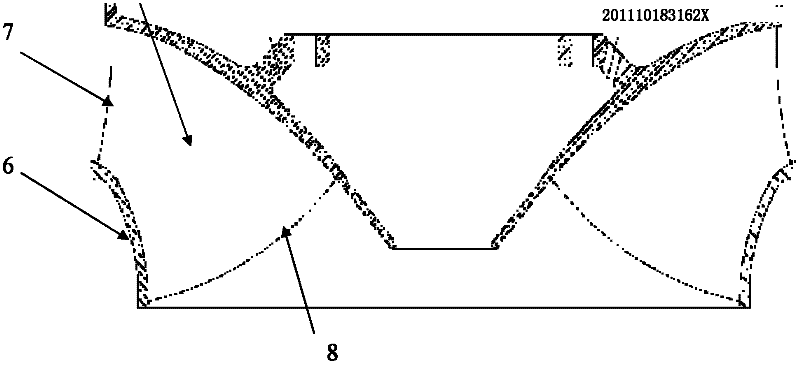

[0037] Such as image 3 As shown, the upper crown of the water turbine is 4, the blades of the water turbine are 5, the lower ring of the water turbine is 6, the water inlet edge of the water turbine blade is 7, and the water outlet edge of the water turbine blade is 8, Figure 4 It is a top view of the water turbine blade, the water turbine blade water inlet edge 7, the water turbine blade working surface 9, the water turbine blade back side 10, and the water turbine blade water outlet edge 8. During the operation of the Francis turbine, the water flow from image 3 The water inlet side shown enters the water turbine, flows through the blade area of the water turbine, does work on the front of the water turbine blade, and finally flows out from the water outlet side. Since the water flow does work on the front of the blade, the pressure of the water flow on the front of the blade is relatively high. Figure 5 It is the pressure distribution diagram on the back of the blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com