Safe and automatic brake of wind power generator

A wind power generator, safe and automatic technology, applied in the direction of reduction gear parts, etc., can solve the problems of large power consumption, insufficient buffering, insufficient buffering, etc., and achieve the effect of saving power and sufficient buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

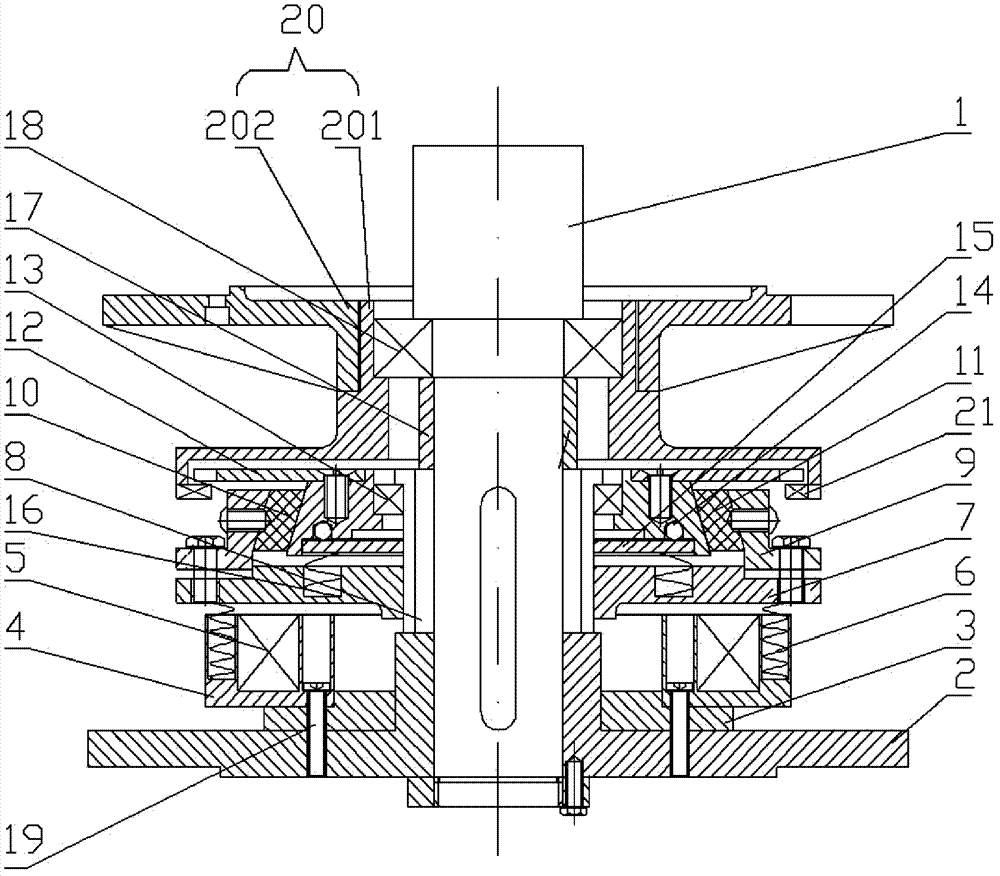

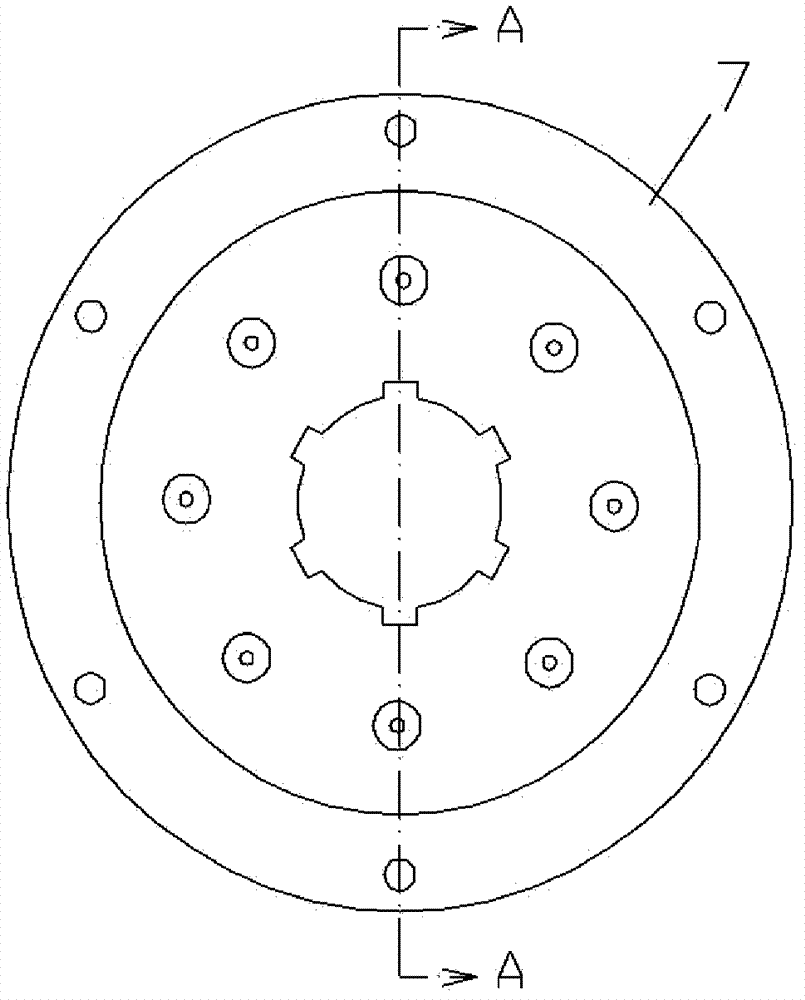

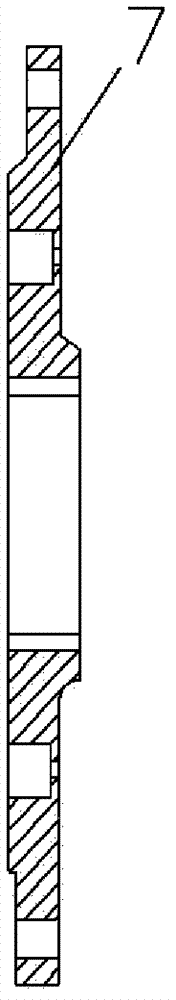

[0025] Example: see Figures 1 to 6 As shown, the safety automatic braking device for wind power generators includes a stator shaft 1 and a base 2, the stator shaft 1 is fixed on the base 2, an aluminum part 3 is fixed on the base 2, a magnetic base 4 is fixed on the aluminum part 3, and an electromagnetic coil 5 Fixed on the magnetic base 4, one end of the first spring 6 acts on the magnetic base 4, and the other end acts on the suspension iron 7;

[0026] The annular suspension iron 7 is inserted on the spline sleeve 8, and the spline sleeve 8 is inserted on the stator shaft 1. The suspension iron 7 and the outer ring 9 are fixed together by screws, and the outer ring 9 is fixed on the conical shaft by screws. On the brake ring 10, the inner inclined ring surface 101 of the tapered brake ring 10 is pressed against the outer inclined ring surface 111 of the brake pad seat 11, the brake pad 12 is fixed on the brake pad seat 11 by screws, and the brake pad seat 11 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com