Template rolling-taking device used for conveying template

A formwork and cover plate technology, which is applied in the field of glass magnesium plate production equipment, can solve the problems of not being able to absorb the formwork, low work efficiency, and influence on the position of the suction plate, and achieve labor-saving operation, improve work efficiency, and save production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

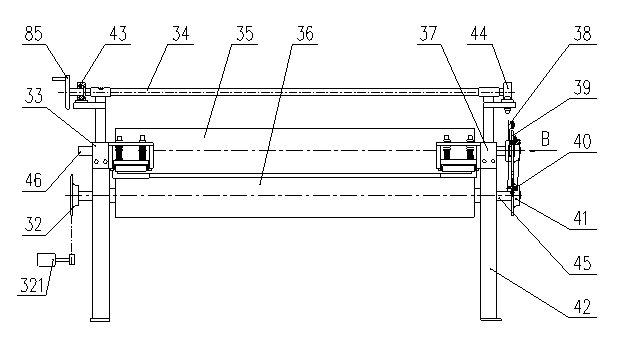

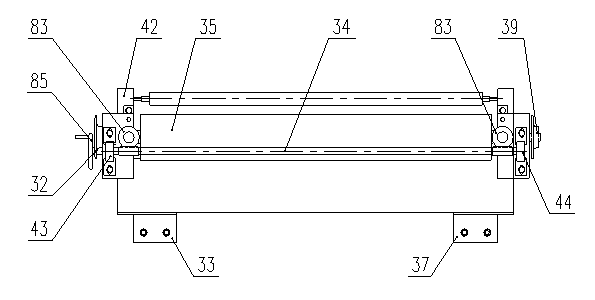

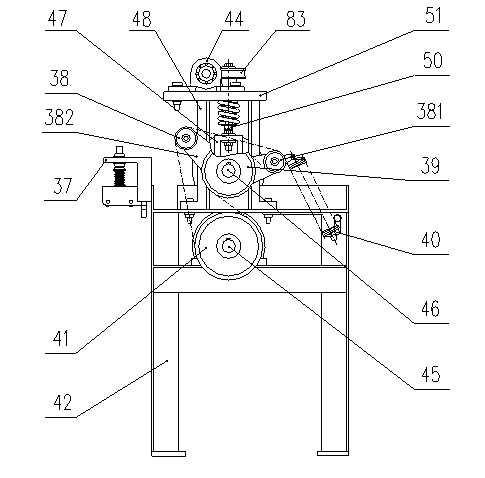

[0021] Such as figure 1 , figure 2 , image 3 As shown, the template rolling device for conveying templates according to the present invention includes: a rolling bracket 42, an upper roller 35 and a lower roller 36 are arranged in the rolling bracket 42, and the lower roller 36 is movably supported by the lower roller shaft 45 In the rolling support 42, in actual production, the lower roll shaft 45 can be movably supported in the rolling support 42 through bearings, and a pair of slide rails 48 are respectively arranged on the upper positions of the rolling support 42 sides, and each pair of slide rails 48 There is an adjustment seat 47 movable in the center, and the adjustment seat 47 can slide up and down in the slide rail 48. The upper roll 35 is movably supported in the adjustment seat 47 through the upper rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com