Automatic feeding device for screw rod machining

An automatic feeding and screw technology, which is applied in the direction of thread cutting device, thread feeding device, metal processing equipment, etc., can solve the problems affecting product quality, high labor intensity of employees, and affecting production safety, so as to improve processing speed and processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

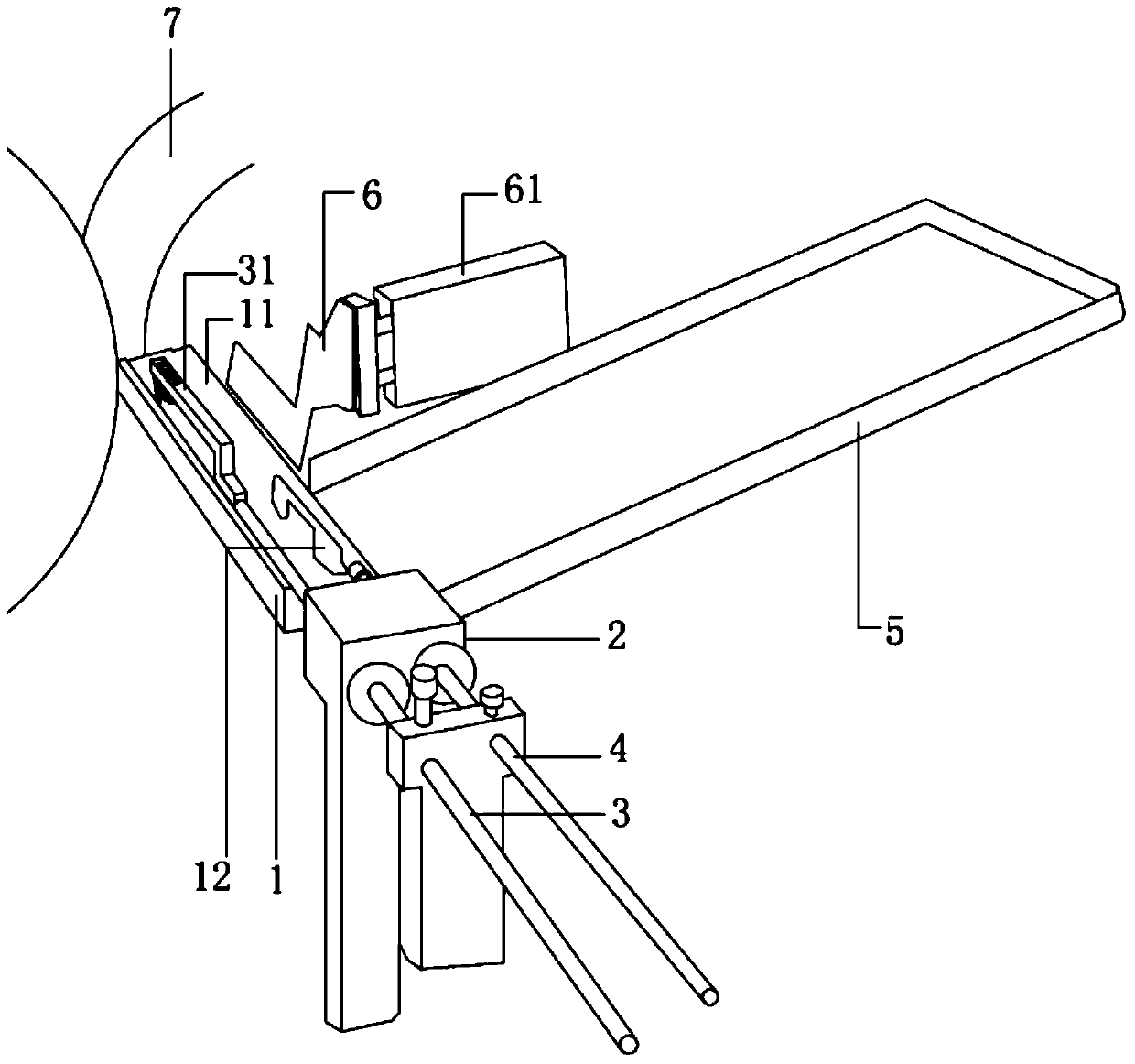

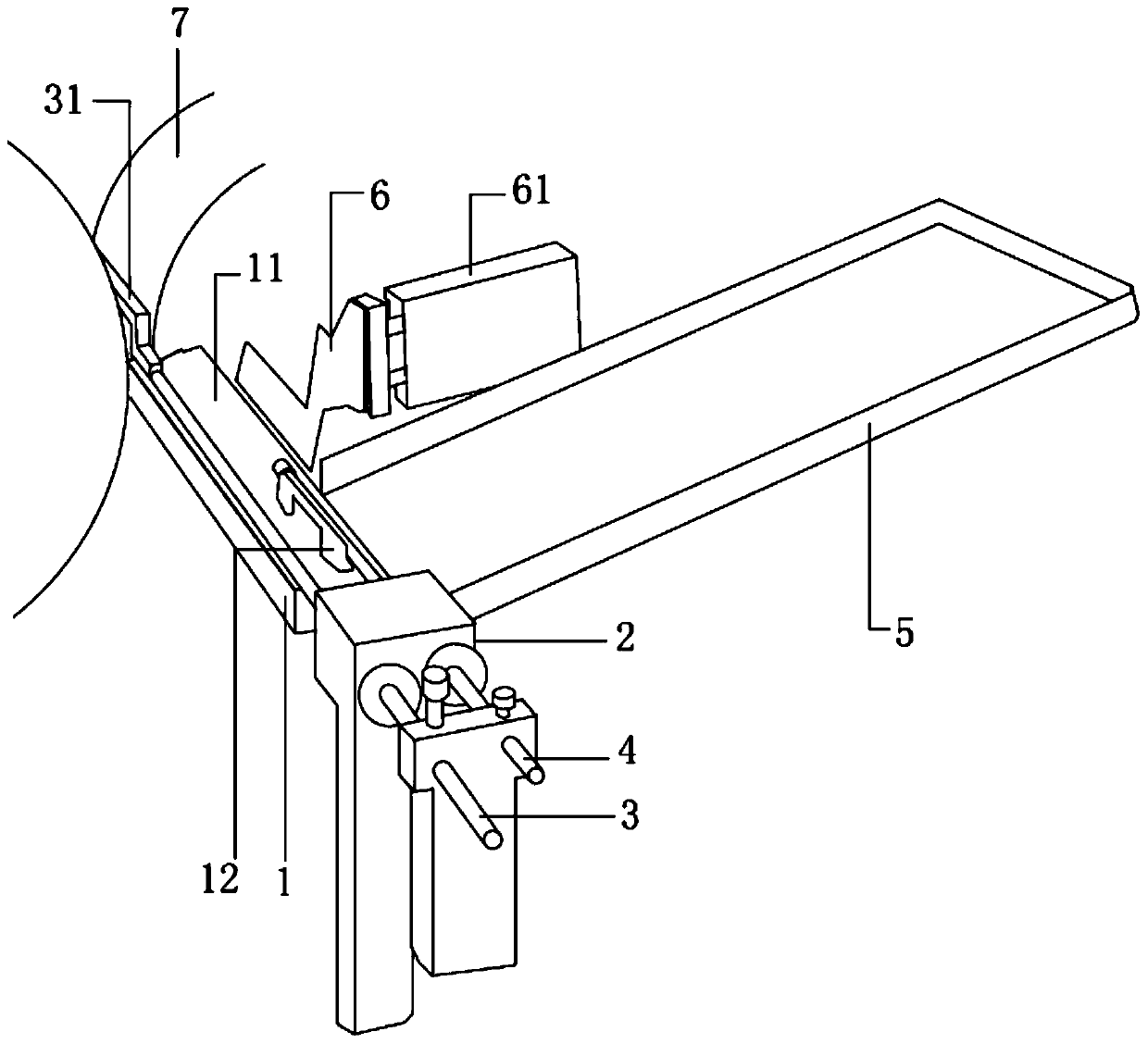

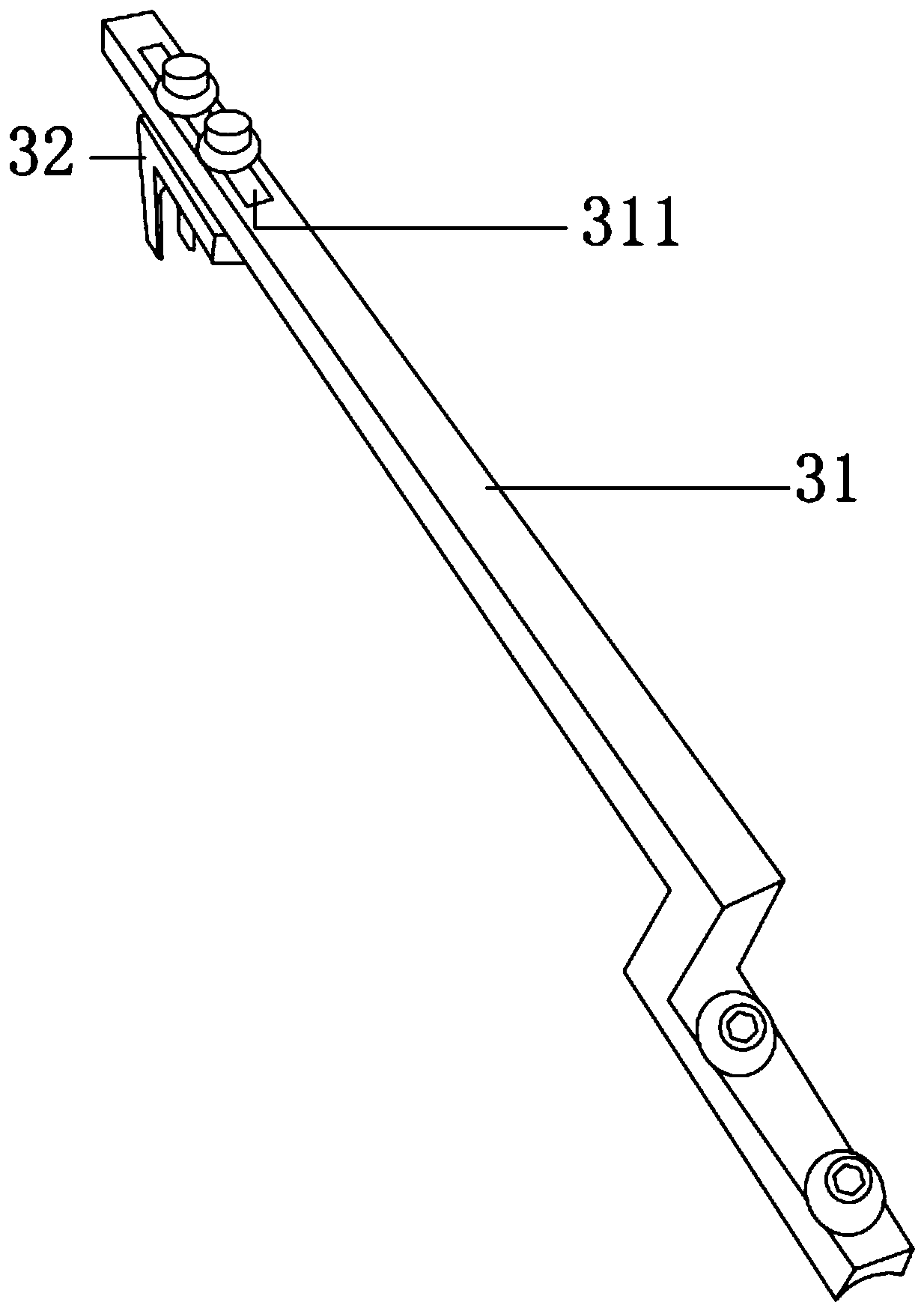

[0023] see Figure 1 to Figure 3 , the figure shows an automatic feeding device for screw mandrel processing provided by Embodiment 1 of the present invention, including: a feeding table 1, a mounting frame 2, a first push rod 3, a second push rod 4, and a feeding tray 5 and the pushing plate 6, one end of the length direction of the feeding table 1 is against the grinder 7, the feeding table 1 is arranged perpendicular to the grinding machine 7, the installation frame 2 is fixedly installed on the other end of the length direction of the feeding table 1, and the first push rod 3 and the second push rod 4 pass through the mounting frame 2, the first push rod 3 and the second push rod 4 are arranged along the length direction of the loading table 1, the first push rod 3 and the second push rod 4 are arranged in parallel, the second push rod 3 The end of a push rod 3 is provided with a pusher clip 31, and the end of the pusher clip 31 is provided with a limit block 32, and the f...

Embodiment 2

[0031] see Figure 1 to Figure 3 , the figure shows an automatic feeding device for screw mandrel processing provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: the first The side of the first push rod 3 is higher than the side of the second push rod 4 , and the contact surface between the table 11 and the first push rod 3 is an arc surface.

[0032] In order to prevent the unprocessed screw rod and the processed screw rod from falling into the unloading device when the pusher plate pushes the unprocessed screw rod, the table of the workbench is set so that the table on the side of the first push rod is higher than that of the second The table on one side of the push rod acts as a barrier to the unprocessed screw rod.

Embodiment 3

[0034] see Figure 1 to Figure 3 , the figure shows an automatic feeding device for screw mandrel processing provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the blocking block 12 and The contact surface of the screw rod is an arc surface.

[0035] In order to make the surface of the blocking block better adhere to the surface of the screw rod and make the second push rod more smooth when pushing the screw rod, the contact surface between the blocking block and the screw rod is an arc-shaped surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com