Automatic capturing and moving device for cover mould of concrete pipe pile

A technology of concrete pipe piles and mobile devices, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of hook slippage, low work efficiency, and high labor intensity of workers, so as to achieve good locking effect, improve work efficiency, The effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

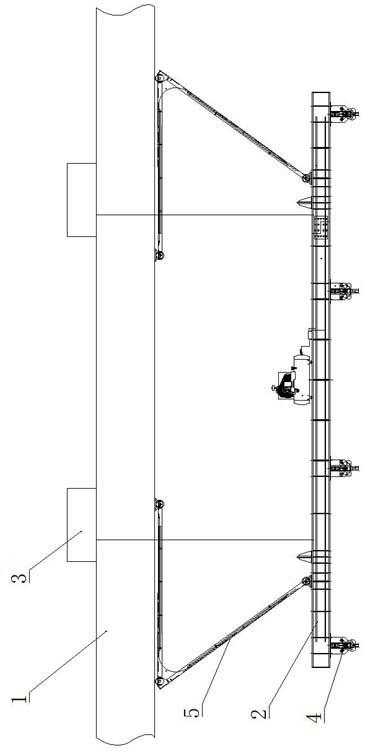

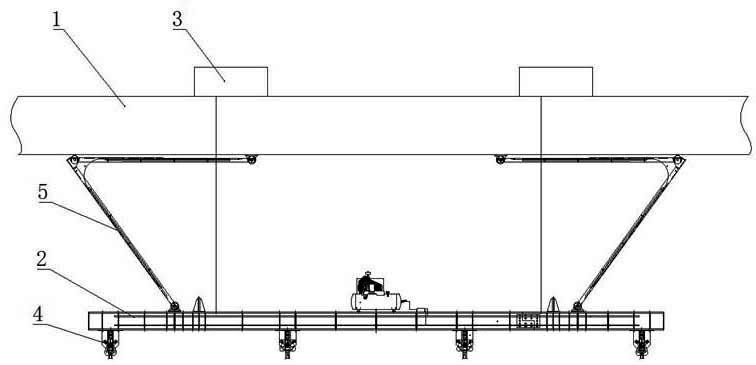

[0011] like figure 1 As shown, it includes a beam 1, a movable spreader 2, a lifting trolley 3, a mechanical claw 4, and a folding arm 5.

[0012] A movable spreader 2 is arranged below the crossbeam 1 of the above-mentioned row crane, and the movable spreader 2 is connected with the lifting trolley 3 on the crossbeam 1 through a wire rope.

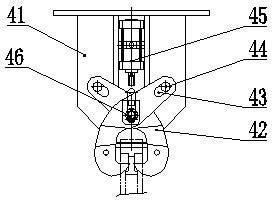

[0013] Some mechanical claws 4 are installed on the movable spreader 2, such as figure 2 As shown, the mechanical claw 4 includes a bracket 41 fixed on the movable sling 2, a pair of hooks 42 arranged crosswise in an X shape, the lower end of the hook 42 is a hook portion, and a waist-shaped hole 43 is opened at the upper end of the hook 42. The waist-shaped hole 43 is pierced with a positioning pin 44 fixedly connected to the bracket 41, and the center intersection of the pair of hooks 44 is connected by a pin shaft 46, and a drive cylinder 45 is connected to the pin shaft 46. In this embodiment, the driving cylinder 45 is a driving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com