Arc extinguish chamber device for circuit breaker

A technology for arc extinguishing chambers and circuit breakers, which is applied to circuits, electrical components, and electrical switches. It can solve problems such as reduced arc ignition performance, increased carbonization area of arcs, and inability to cut arcs, so as to improve breaking performance and technical solutions. Simple, good arc extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

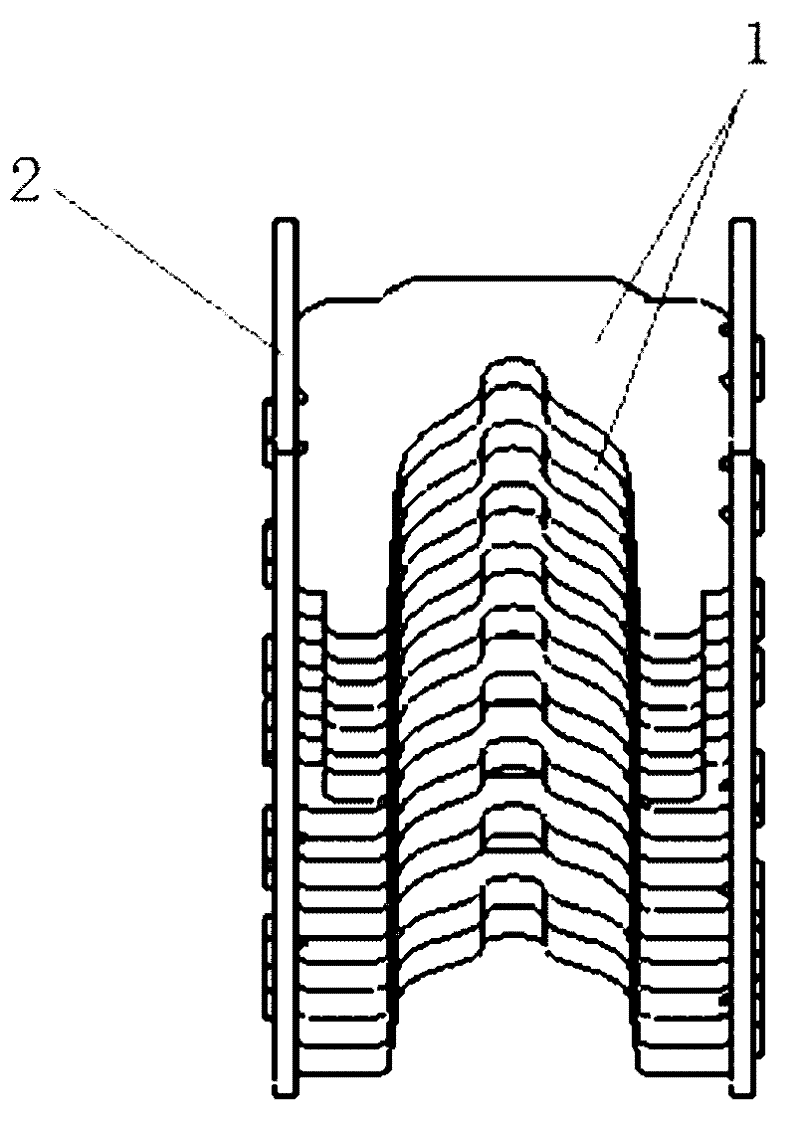

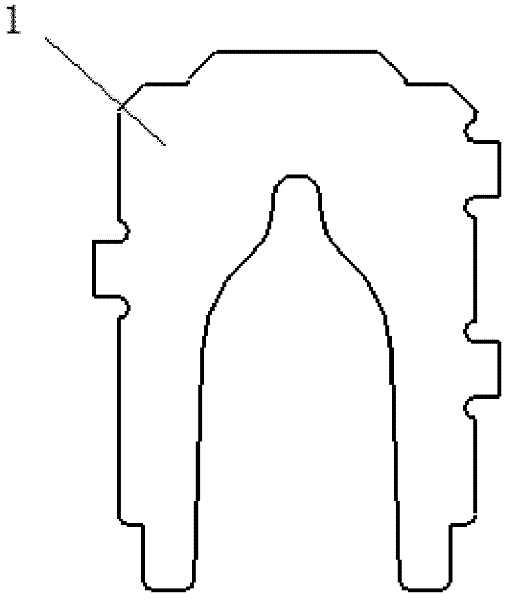

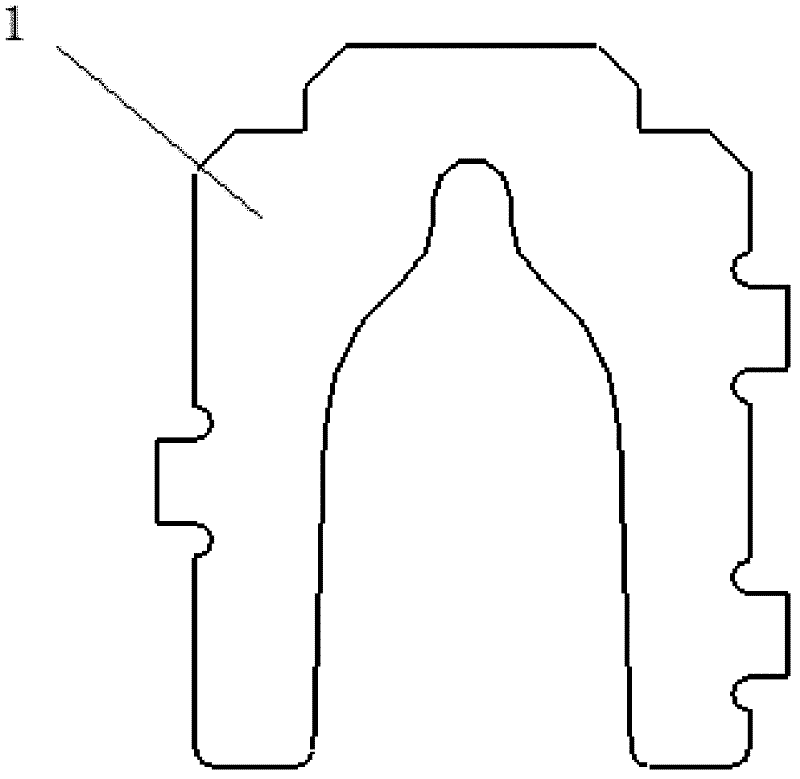

[0031] Example: first combine figure 1 , figure 2 , image 3 , Figure 4 As shown, it can be known that the existing circuit breaker arc extinguishing chamber device has the same shape and size of the gaps at the bottom of the arc extinguishing grid sheets 1 adjacent up and down (both are left-right symmetrical "bottle-shaped" gaps). When assembling, the arc extinguishing grid The sheets 1 are neatly arranged and overlapped, and are not staggered, so that the arc generated after the circuit breaker is broken cannot be effectively cut, resulting in a decrease in the arc extinguishing performance of the circuit breaker. In addition, in the existing arc extinguishing chamber device, the arc extinguishing grid 1 located at the top and responsible for arc striking lacks an effective arc striking position, so that the arc generated after the circuit breaker is broken cannot enter the arc extinguishing chamber quickly and effectively; at the same time, the two The side arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com