Wire Spool Supporting Device And Locking Structure Of Threaded Connection Component

A supporting device and winding reel technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of cumbersome replacement of winding reels, cumbersome operations, forgetting to press screws and screwing in operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

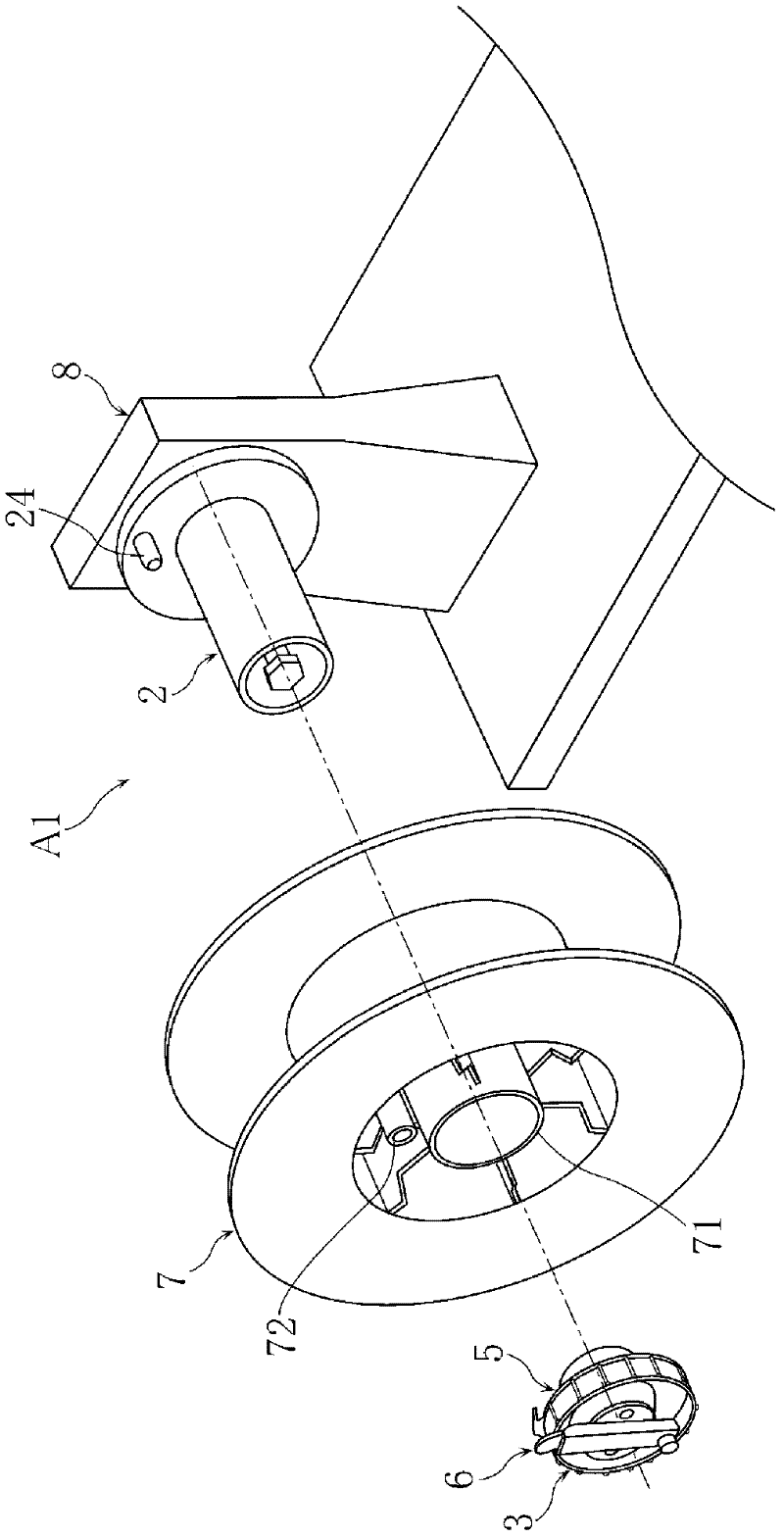

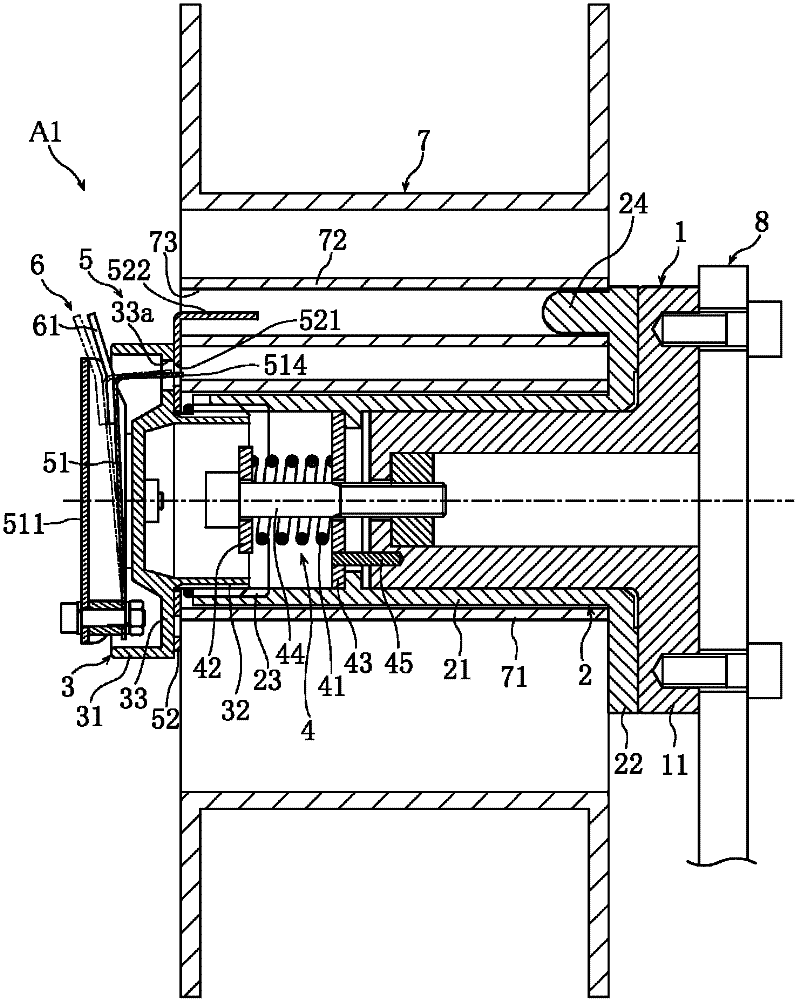

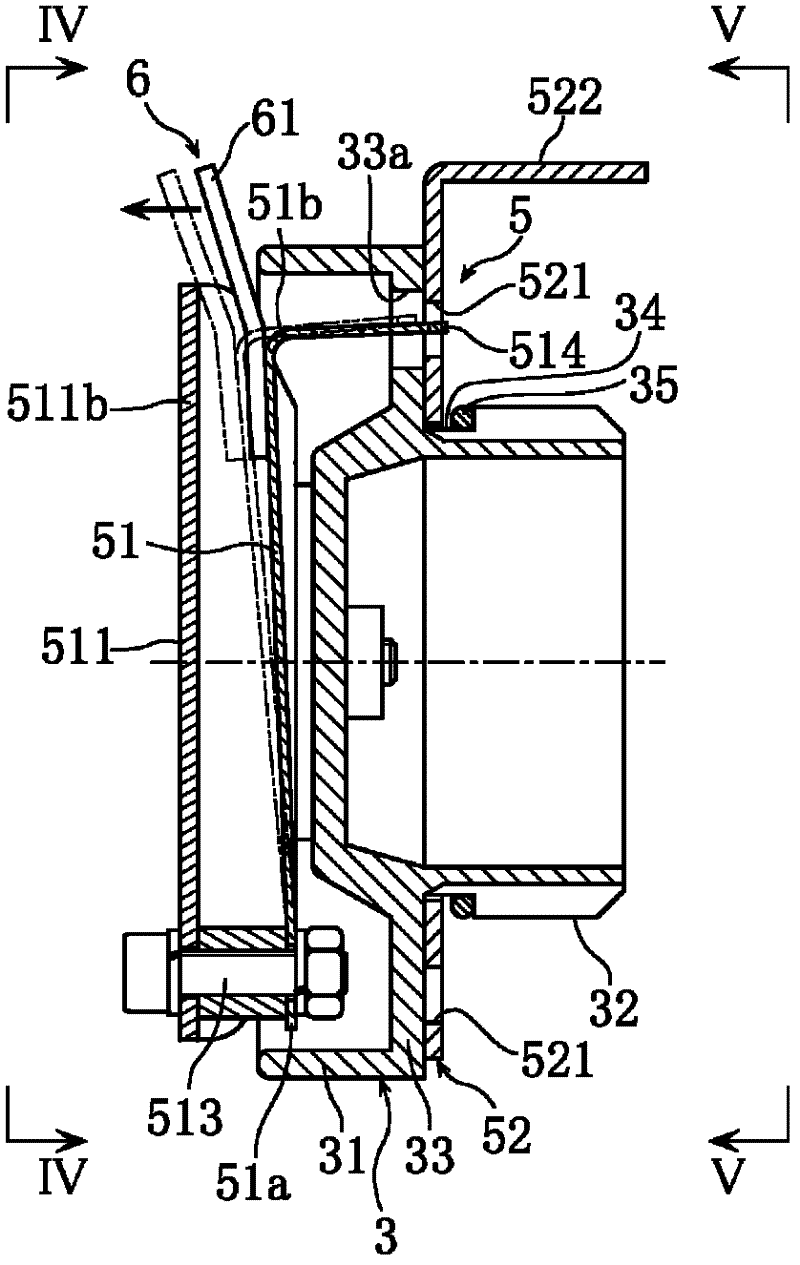

[0070] figure 1 as well as figure 2 The bobbin support device which concerns on 1st Embodiment of this invention is shown. The reel support device A1 of the present embodiment includes a fixed shaft 1 , a rotating body 2 , a cap member 3 , a rotating body brake mechanism 4 , a lock mechanism 5 , and a lock release mechanism 6 .

[0071] A flange 11 is provided at the base end of the fixed shaft 1 , and the flange 11 is fastened to the upright support plate 8 by bolts.

[0072] The rotating body 2 has a cylindrical body portion 21 fitted on the fixed shaft 1 , a flange 22 provided at the proximal end of the body portion 21 , and a threaded portion 23 . The rotating body 2 is rotatably supported on the rotating shaft 1 . A detent pin 24 extending in the axial direction is erected on the flange 22 . A threaded portion 23 formed of a female threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com