Middle pan comprehensive measurement gauge of scraper conveyor for coal mine and measurement method using same

A technology of scraper conveyors and comprehensive inspection tools, which is applied in the direction of mechanical measuring devices, mechanical gap measuring, measuring devices, etc., can solve problems that affect product installation and performance, cannot guarantee product quality, and the measurement results are not accurate enough, etc., to achieve The effect of flexible and convenient use, control of product quality, and simplified measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

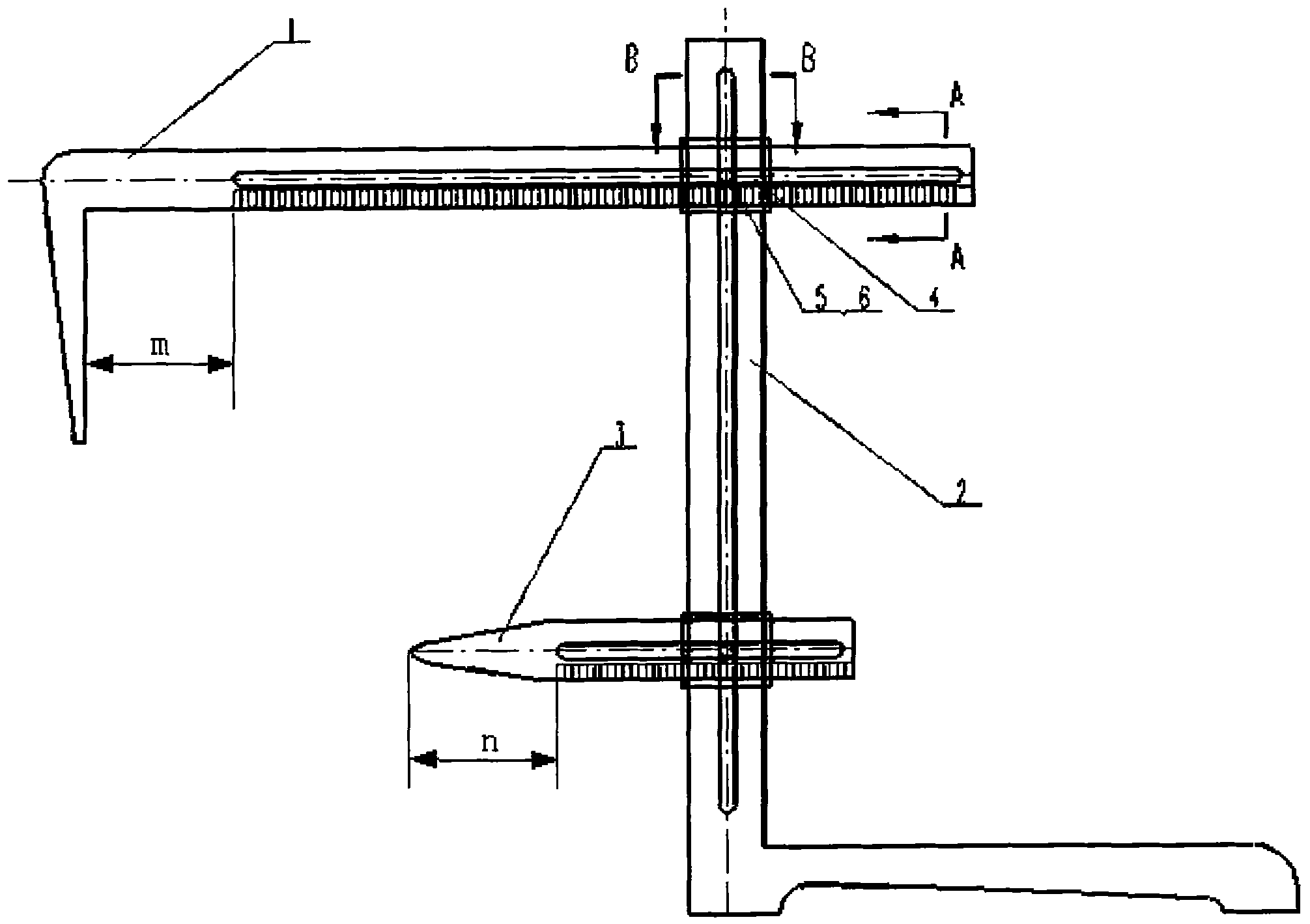

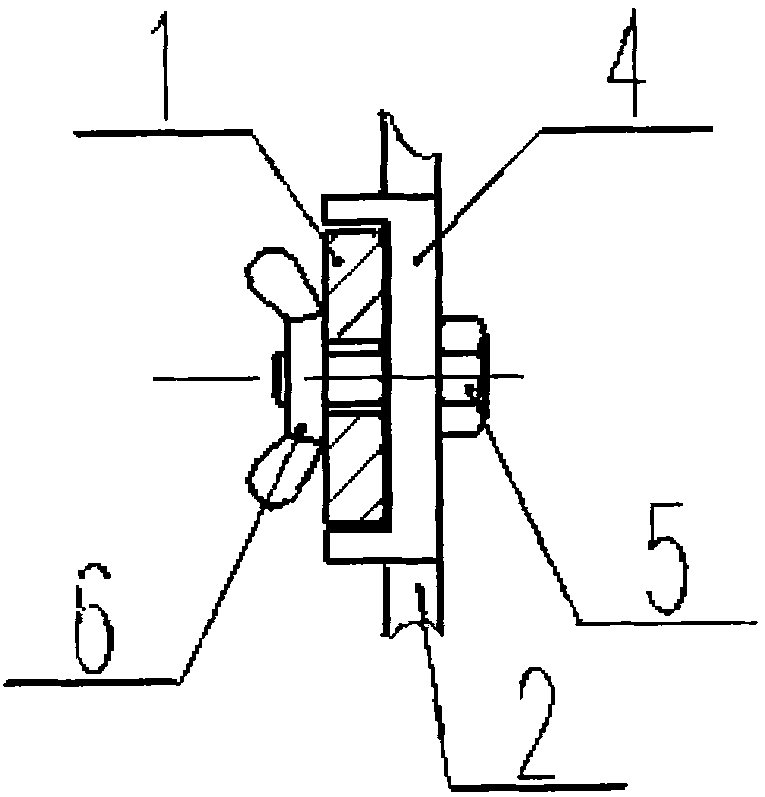

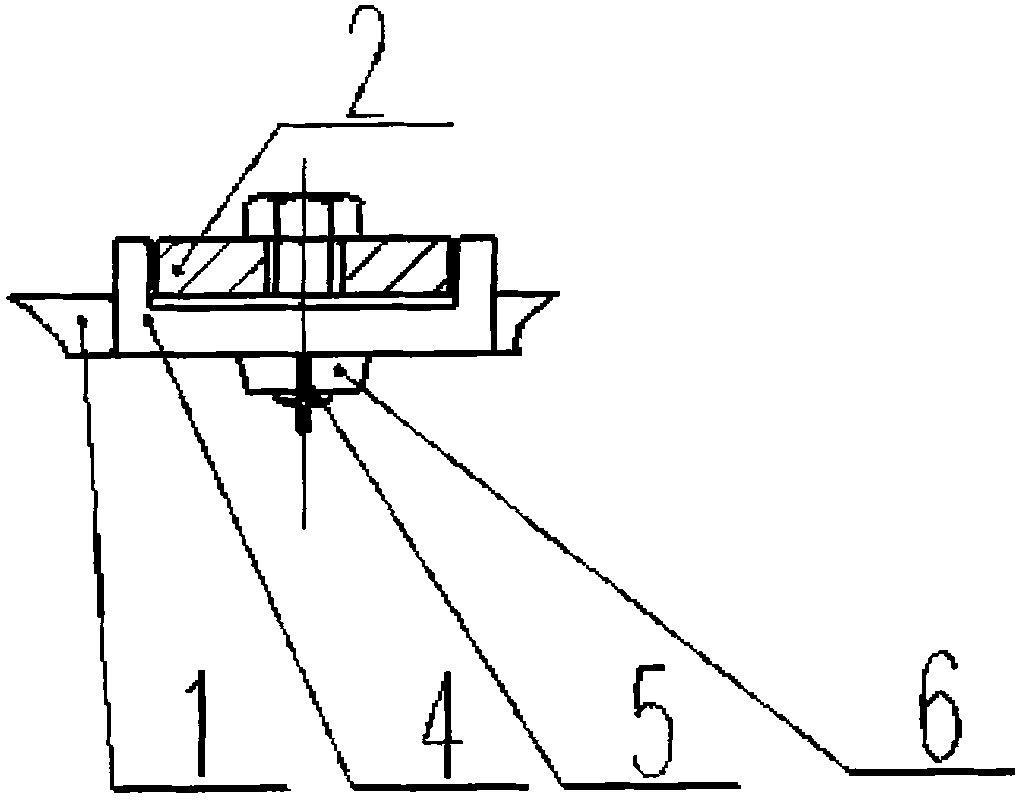

[0021] In the figure: 1 main scale, 2 combination base, 3 auxiliary scales, 4 positioning guide rails, 5 screws, 6 wing nuts;

[0022] a: The horizontal distance from the width of the groove on the middle groove to the inner surface of the rail seat;

[0023] b: The horizontal distance from the inner opening of the upper groove width of the middle groove to the inner side of the bent plate;

[0024] c: the horizontal distance from the inner opening of the upper groove width of the middle groove to the outer side of the bent plate;

[0025] d: rail seat groove width;

[0026] m: the distance from the measuring surface (point) of the main ruler to the zero position of the scale;

[0027] n: the distance from the measuring point of the sub-scale to the zero position of the scale.

[0028] Depend on Figure 1~3 As shown, it is composed of main ruler 1, combined base 2, auxiliary ruler 3, positioning guide rail 4, screw 5 and wing nut 6; The measuring surface is the inner plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com