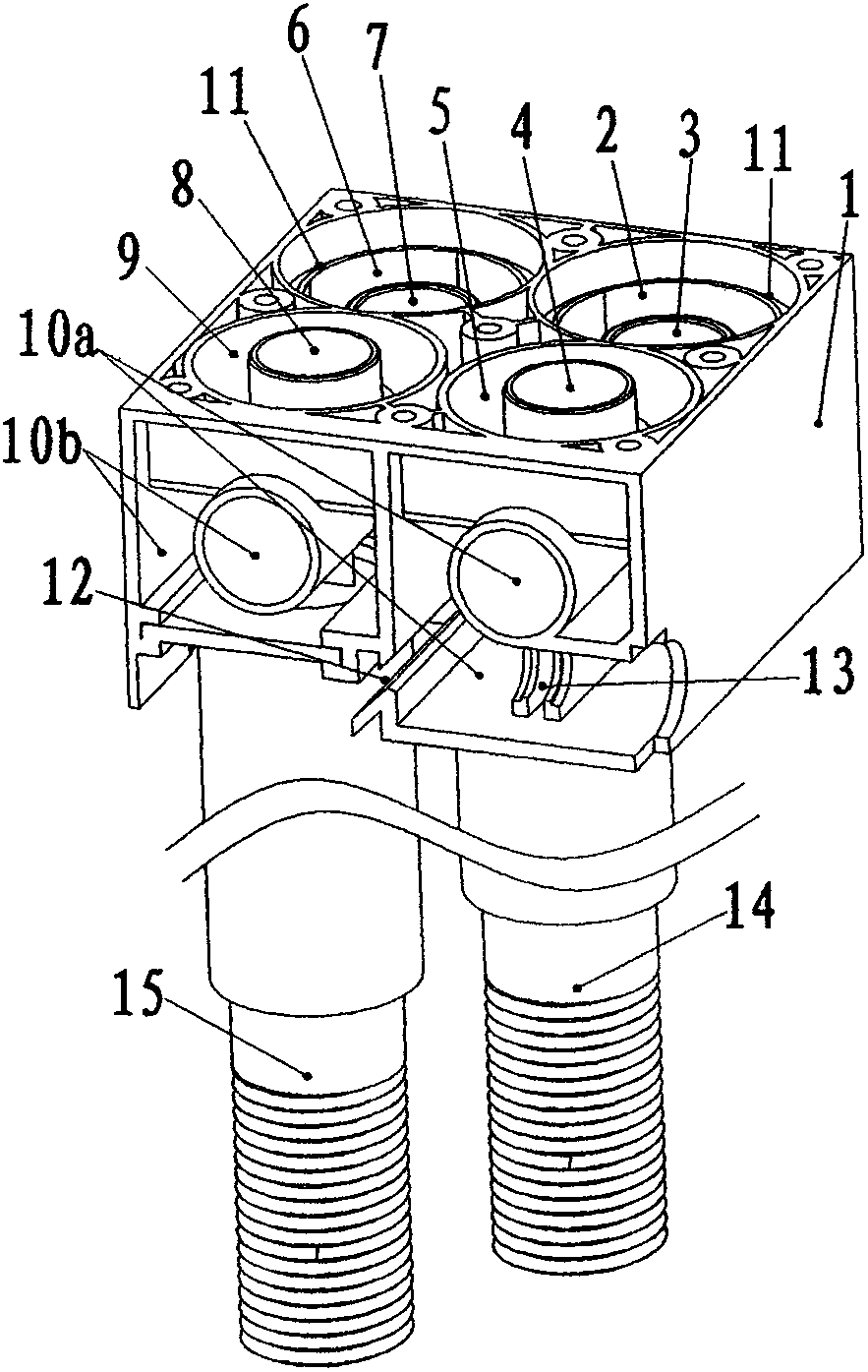

Injection water-saving valve

A jet valve and water-saving valve technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of high water pressure requirements, loud noises, low water pressure, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

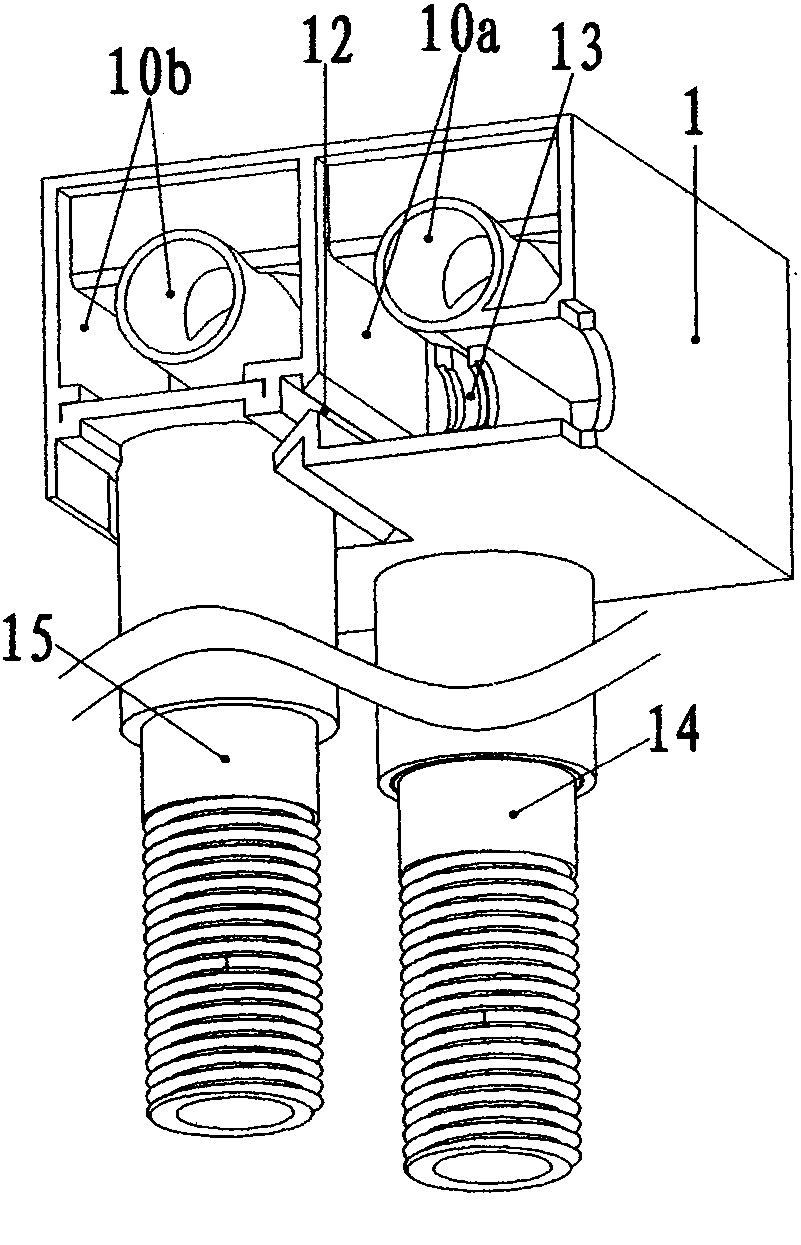

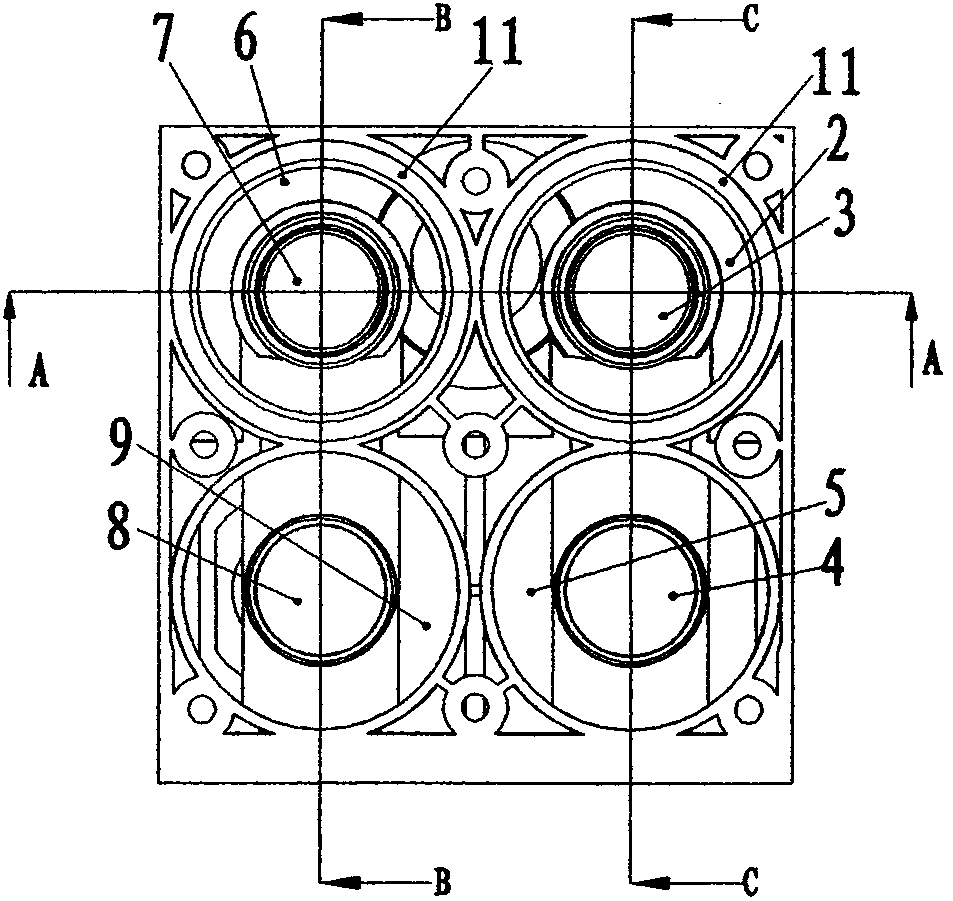

Method used

Image

Examples

specific Embodiment approach 2

[0142] In the first embodiment, the water outlet 12 is above the jet valve float tank B. The purpose of this design is to conveniently guide the water flowing from the water outlet 12 to the jet valve float tank B so that the water in the jet valve float tank B In order to achieve this goal, there are actually many ways to close the jet valve float mechanism 30. The water outlet 12 does not have to be above the jet valve float tank B. In the second embodiment, the water outlet 12 It is connected with the jet valve floating body tank B with a communicating pipe, so that all or part of the water flowing out of the water outlet 12 flows to the jet valve floating body tank B and then into the water tank, thus achieving the purpose as in the first embodiment, and the rest All the components are exactly the same as those in the first embodiment, and the working principles and steps are also exactly the same, so the oblique description will not be repeated here.

[0143] To add a note: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com