Main component device for ultrahigh-combustion micro-emission energy-saving high-pressure engine for various tail gas compound cylinders

A technology of ultra-high pressure and composite cylinders, which is applied to engine components, combustion engines, internal combustion piston engines, etc., can solve the problems of low energy saving effect and poor engine feasibility, and achieve the effect of simple structure, stable performance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

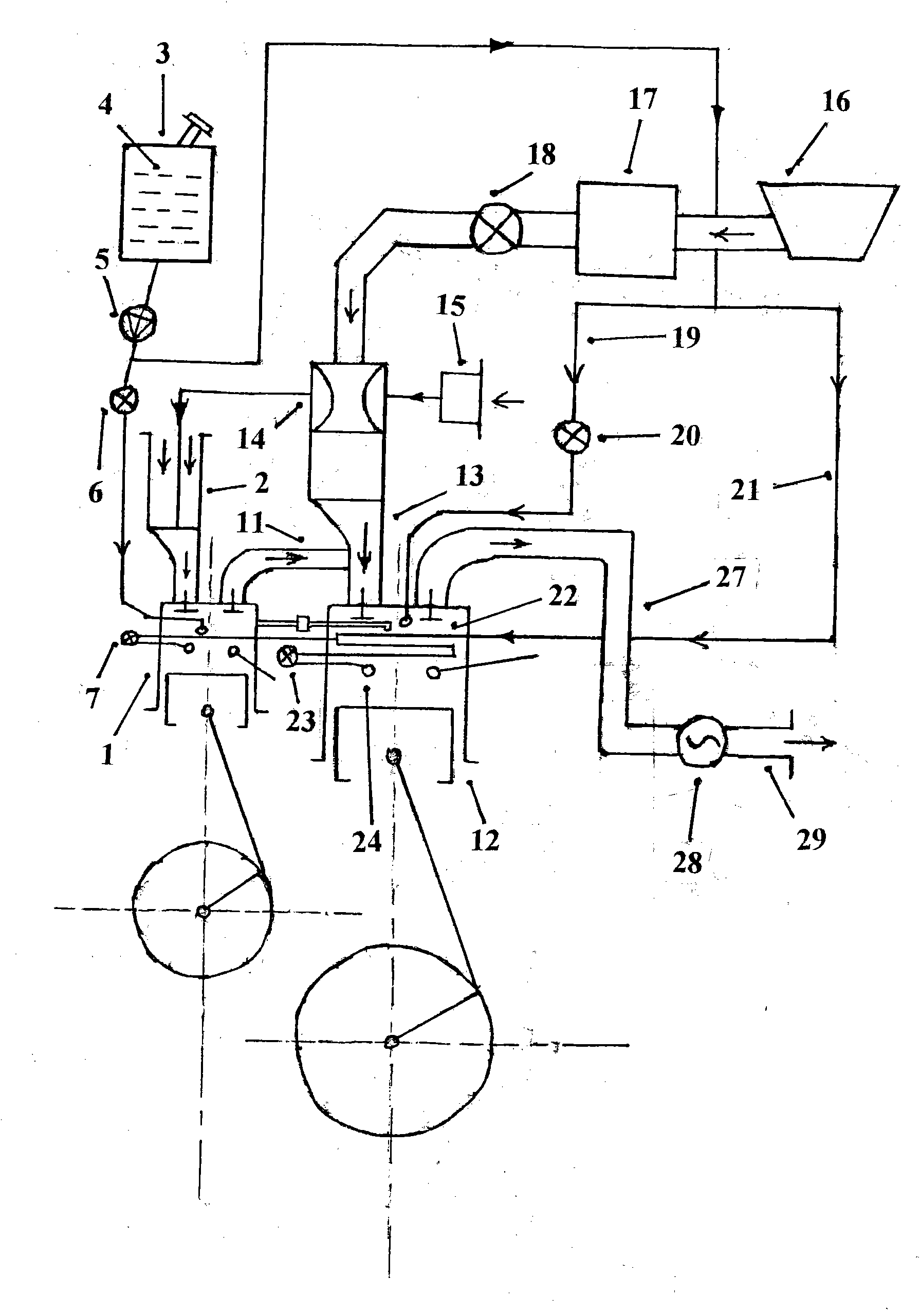

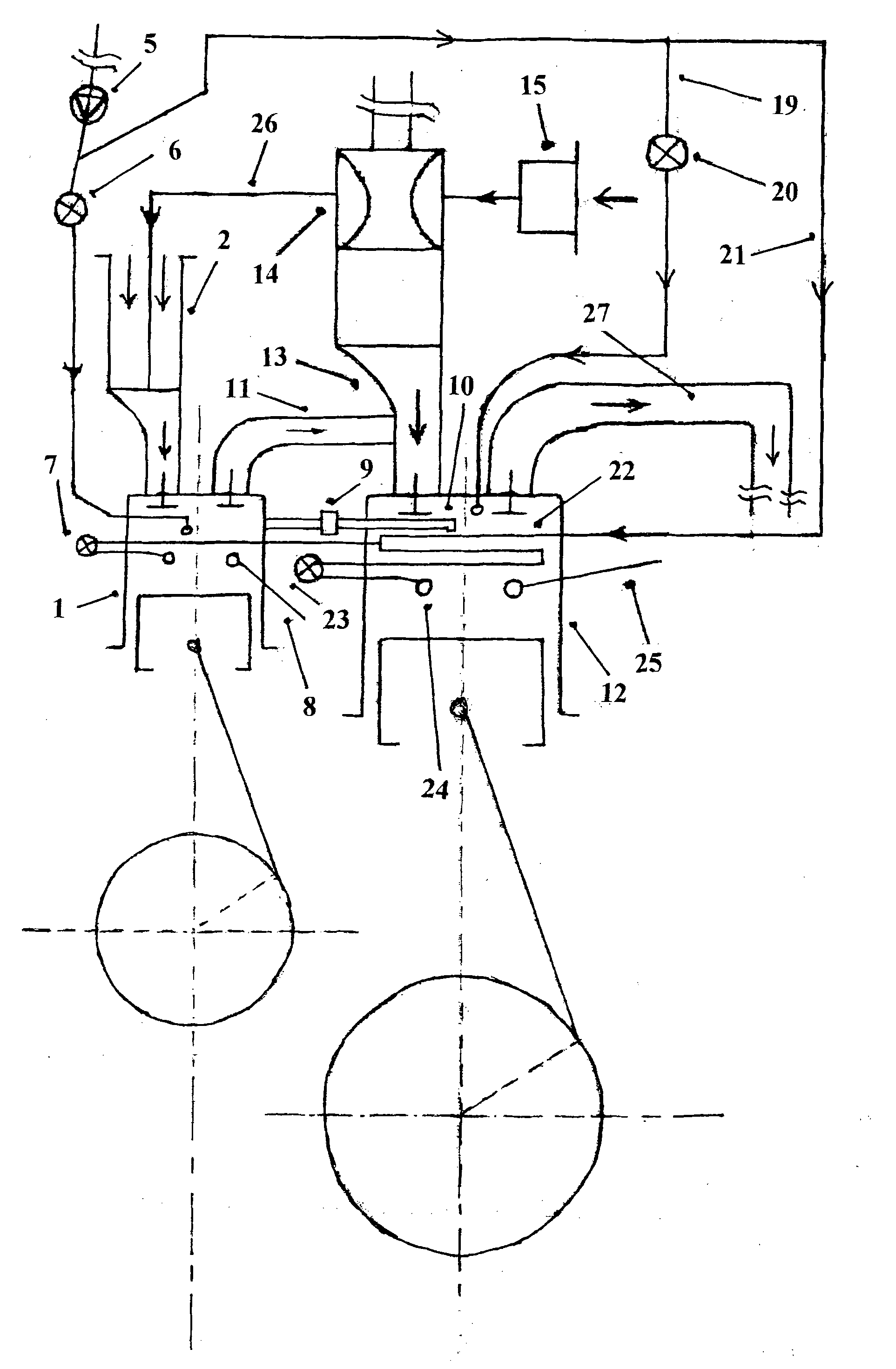

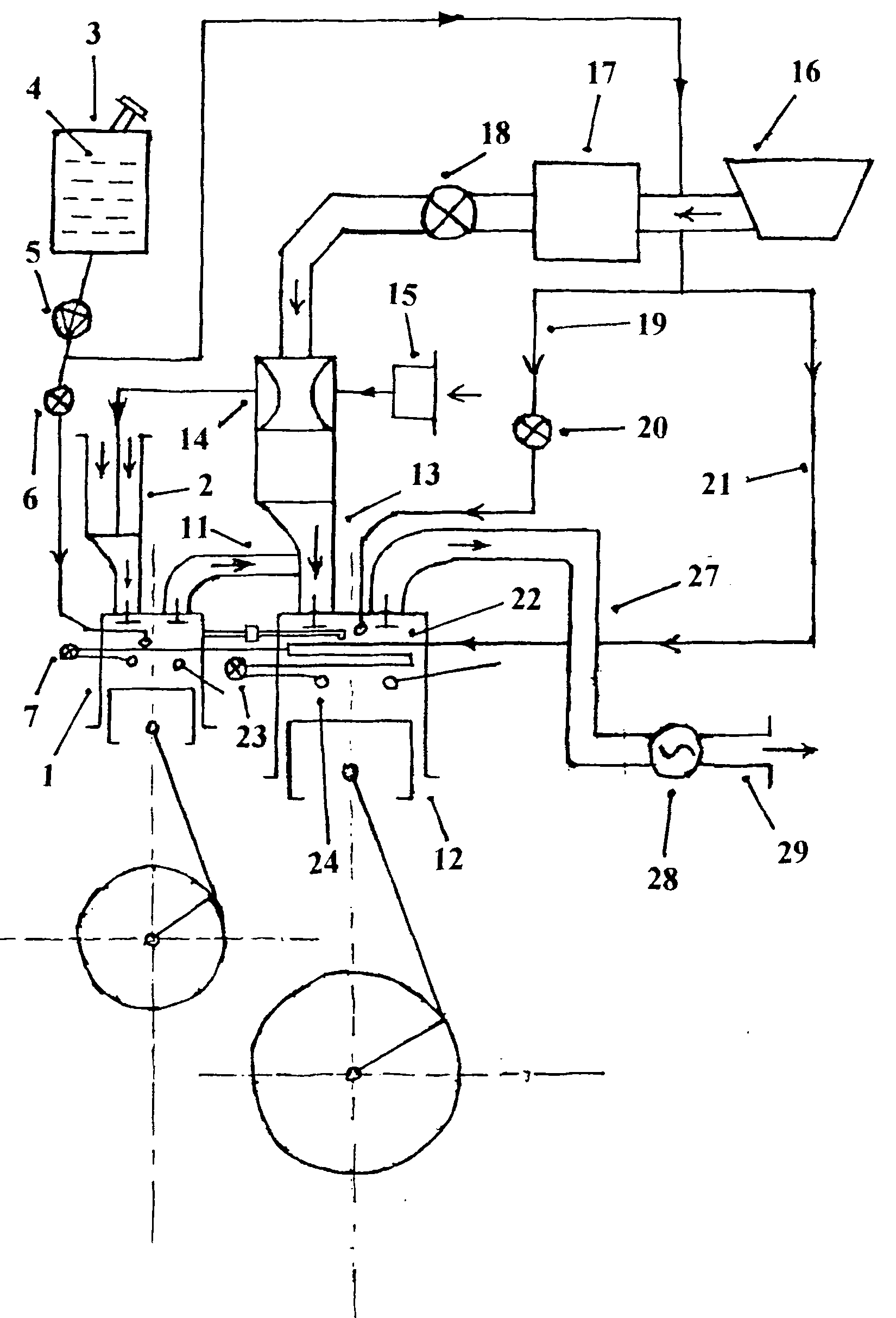

[0011] exist figure 1 Among them, the fuel tank (3), high-energy fuel (4), ultra-high-pressure fuel pump (5), ultra-high-pressure fuel Enter the pre-injection and pre-mixing control system (6), set a lot of high-energy fuel (4) in the fuel tank (3), and connect one end of the ultra-high pressure fuel pump (5) to the fuel tank (3) and the other end to the ultra-high pressure fuel input The pre-injection pre-mixing control system (6) is connected, and one end of the ultra-high pressure fuel input pre-injection pre-mixing control system (6) is connected with the upper injection head of the miniature ultra-high energy ignition high-pressure cylinder (1). A high-pressure mixed gas input device (2) is set in the high-pressure mixed gas intake input control system on the miniature ultra-high energy ignition high-pressure cylinder (1), and one end of the high-pressure mixed gas input device (2) is connected with the miniature ultra-high energy ignition high-pressure cylinder. (1) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com