Mining inclinometer, bracket inclination angle measuring system and inclination angle measuring method

An inclination sensor and measurement method technology, applied in the direction of measuring inclination, measuring devices, instruments, etc., can solve the problems of high power consumption, occupying multiple interfaces, and unfavorable product safety, so as to reduce system power consumption and avoid topology changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

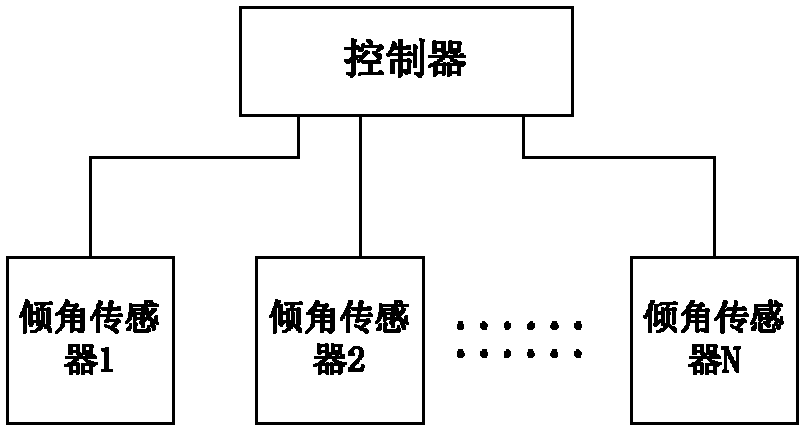

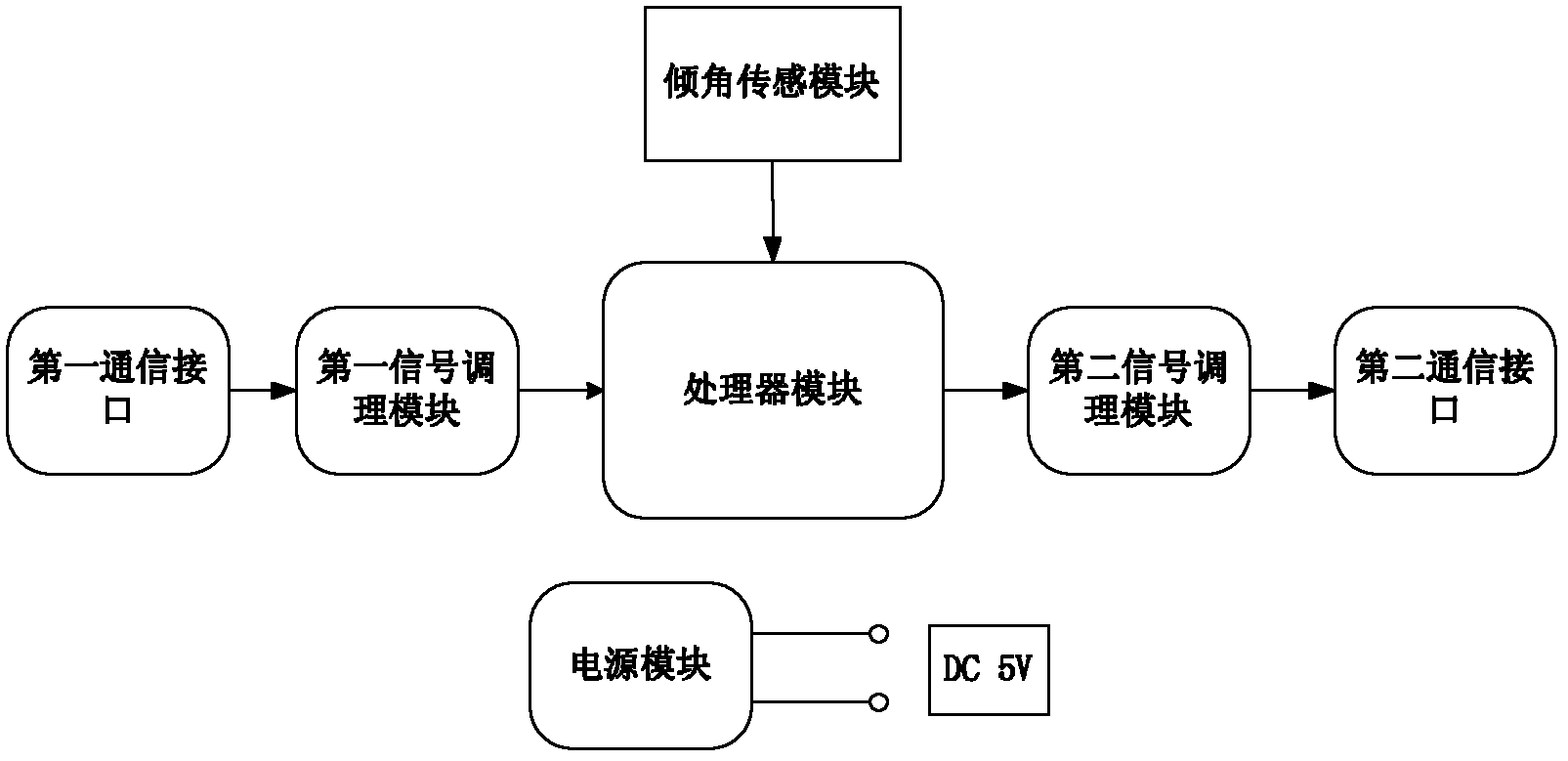

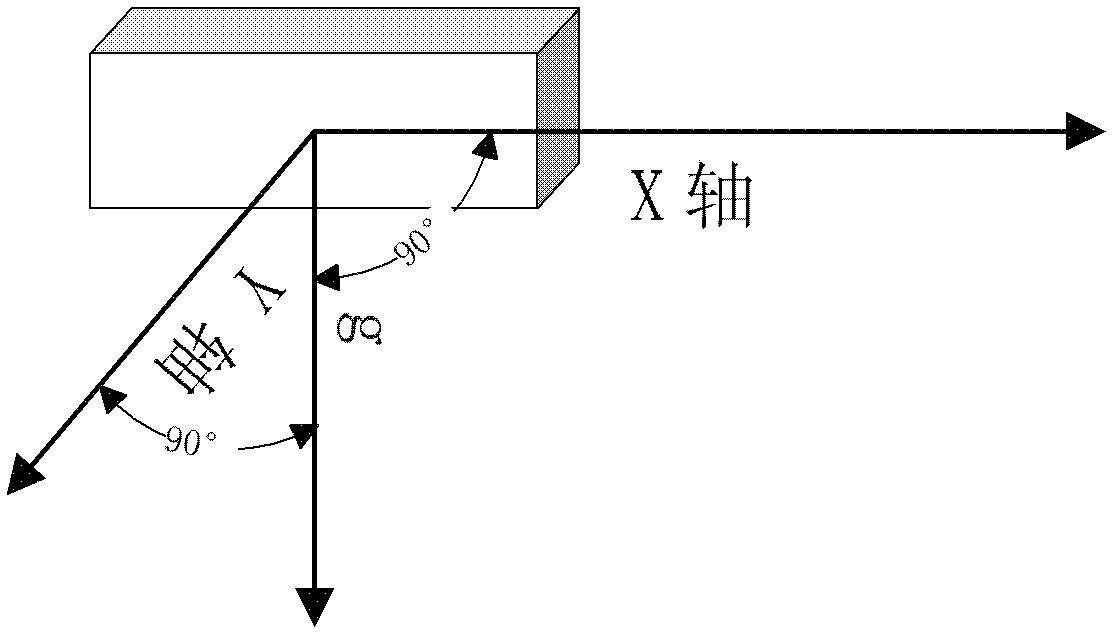

[0029] The inclination sensor of the present invention is mainly installed on various parts of the coal mine hydraulic support, such as the top plate, the bottom plate, the cover beam and other parts; the sensors are connected in series through cables, and the sensor closest to the controller is connected to the support controller , forming an inclination measurement system. The inclination measurement system of the present invention can measure the inclination angle of each part of the support in real time, and obtain the actual posture of the support through combined calculation; the sequential connection between the sensors greatly simplifies the complexity of wiring, and is more suitable for complex underground environments; it only occupies the control of the support Multiple inclination data can be obtained through one interface of the controller, which saves controller resources.

[0030] The inclination sensor of the present invention includes a processing module as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com