Textile-material monitoring device and yarn winding apparatus

A technology for measuring devices and strips, which is applied to measuring devices, optical devices, transportation and packaging, etc., can solve the problems of uneconomical efficiency and low level, and achieve the effect of accurate roughness variation and suppressing the generation of shadows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

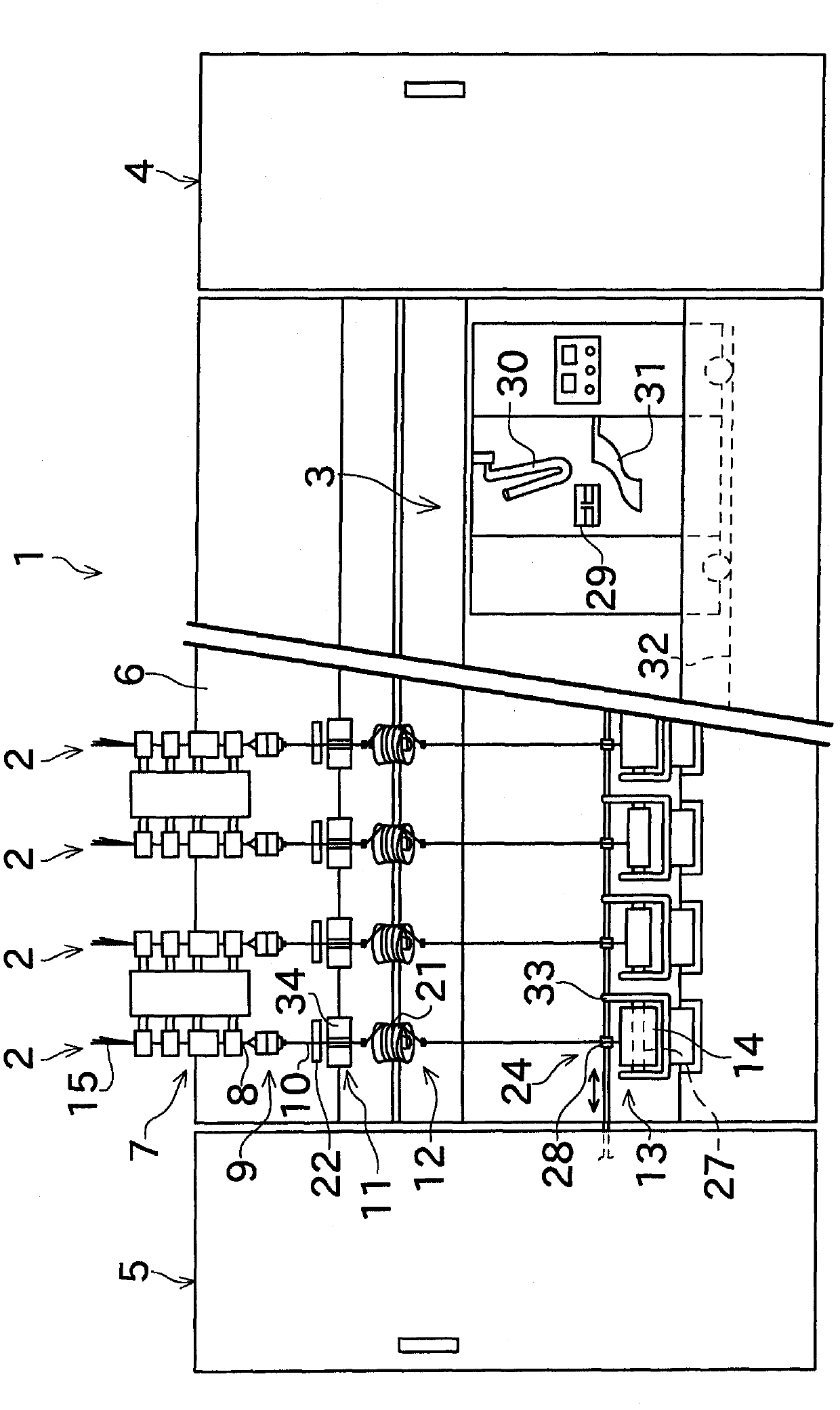

[0035] figure 1The illustrated spinning machine 1 as a yarn winding machine includes a plurality of winder units 2 arranged in parallel, a yarn splicing cart 3 , a blower box 4 , and a prime mover box 5 .

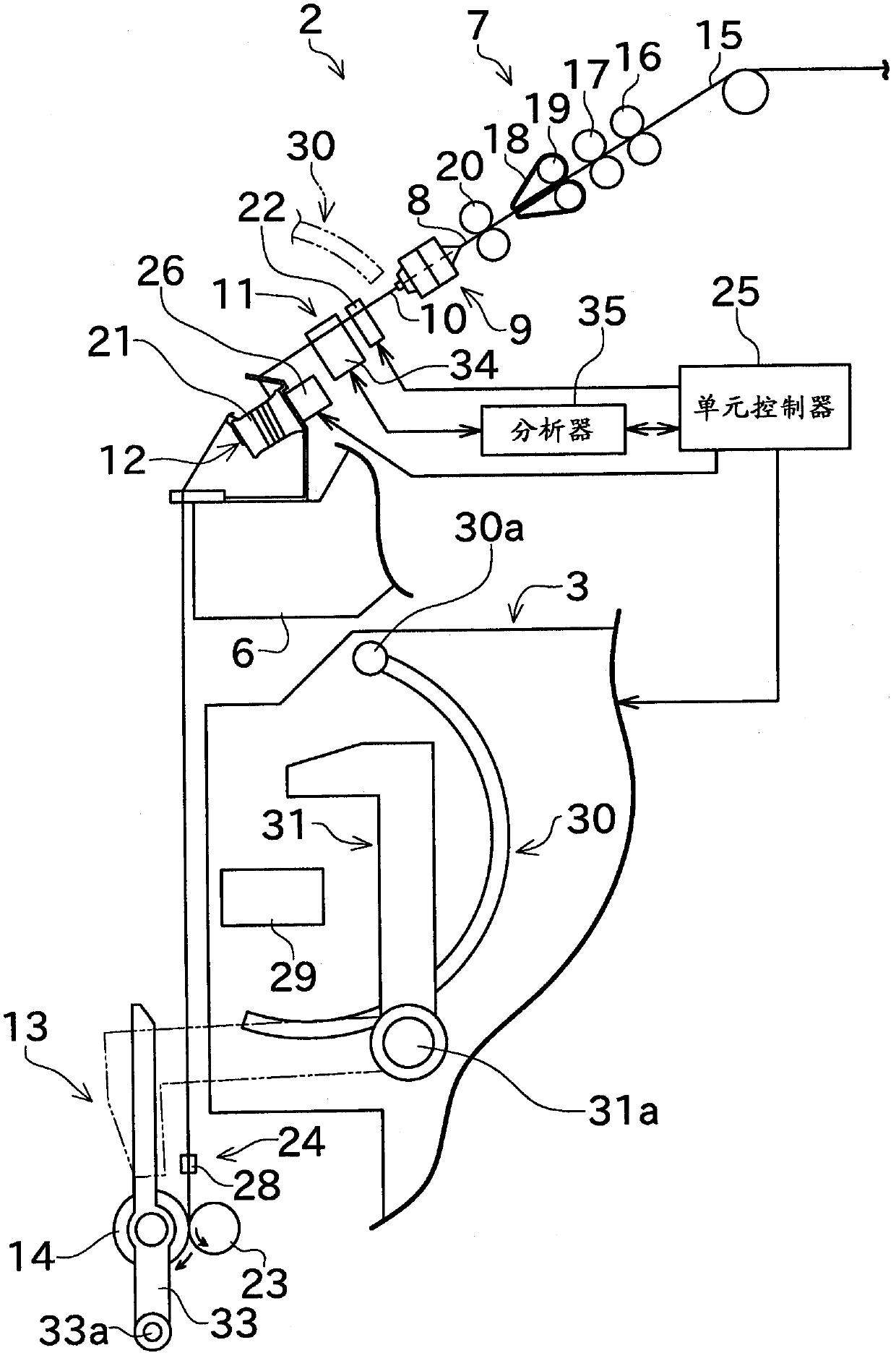

[0036] Each spinning unit 2 is configured by stretching the sliver 15 into a fiber bundle 8 , twisting the fiber bundle 8 to obtain a spun yarn 10 , and then winding the spun yarn 10 to form a package 14 . In addition, the sliver 15, the fiber bundle 8, the spun yarn 10, etc. can be collectively referred to as "fiber strands" because the fibers are connected elongatedly.

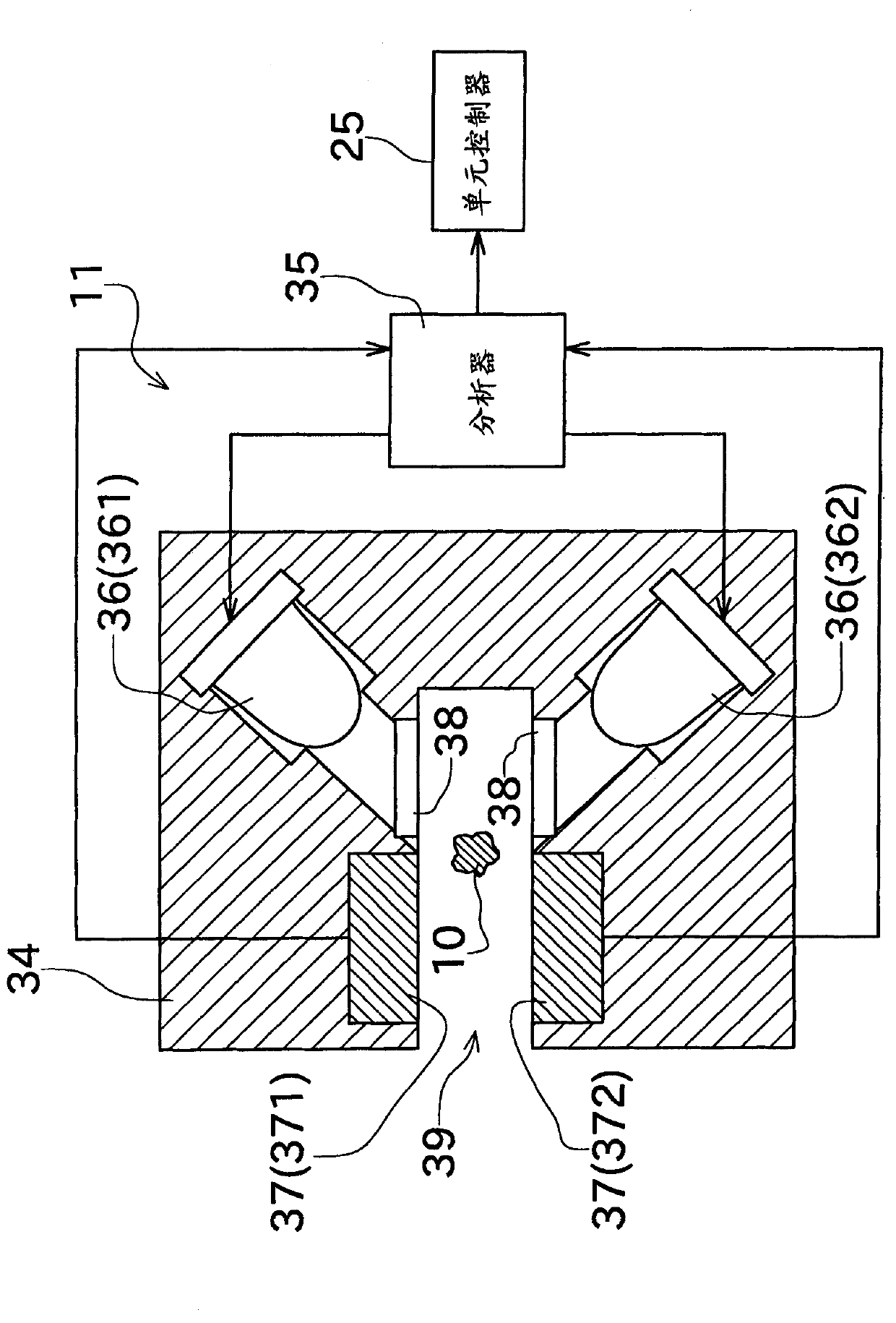

[0037] like figure 1 and figure 2 As shown, each weaving unit 2 has, as main components in order from upstream to downstream: a drafting device 7 , a weaving device 9 , and a winding device 13 . Additionally, if figure 2 As shown, each spinning unit 2 has a unit controller 25 for controlling each configuration of the spinning unit 2 . In addition, "upstream" and "downstream" in this specification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com