Gas sensor performance testing device

A gas-sensing sensor and testing device technology, applied in the field of sensor performance testing devices, can solve the problem that the performance testing device can only simulate a high temperature environment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

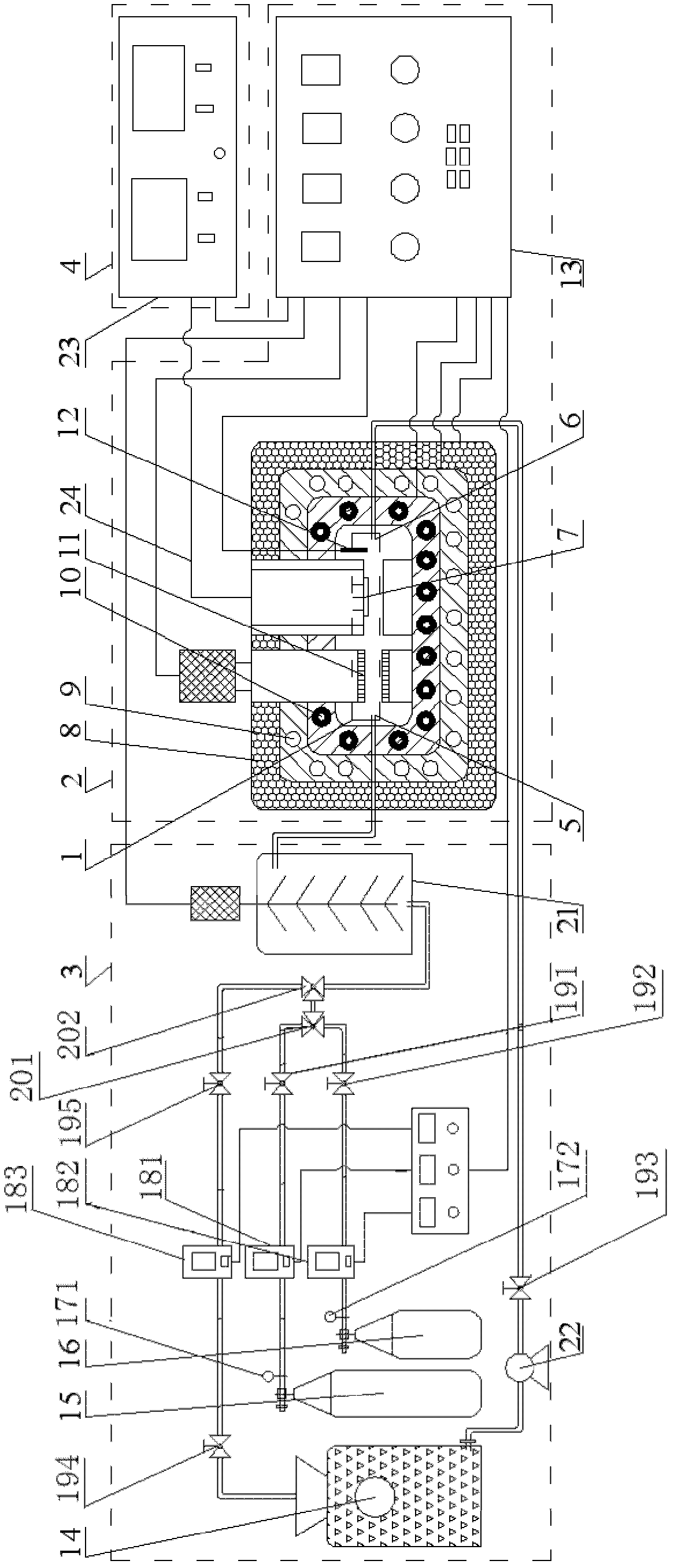

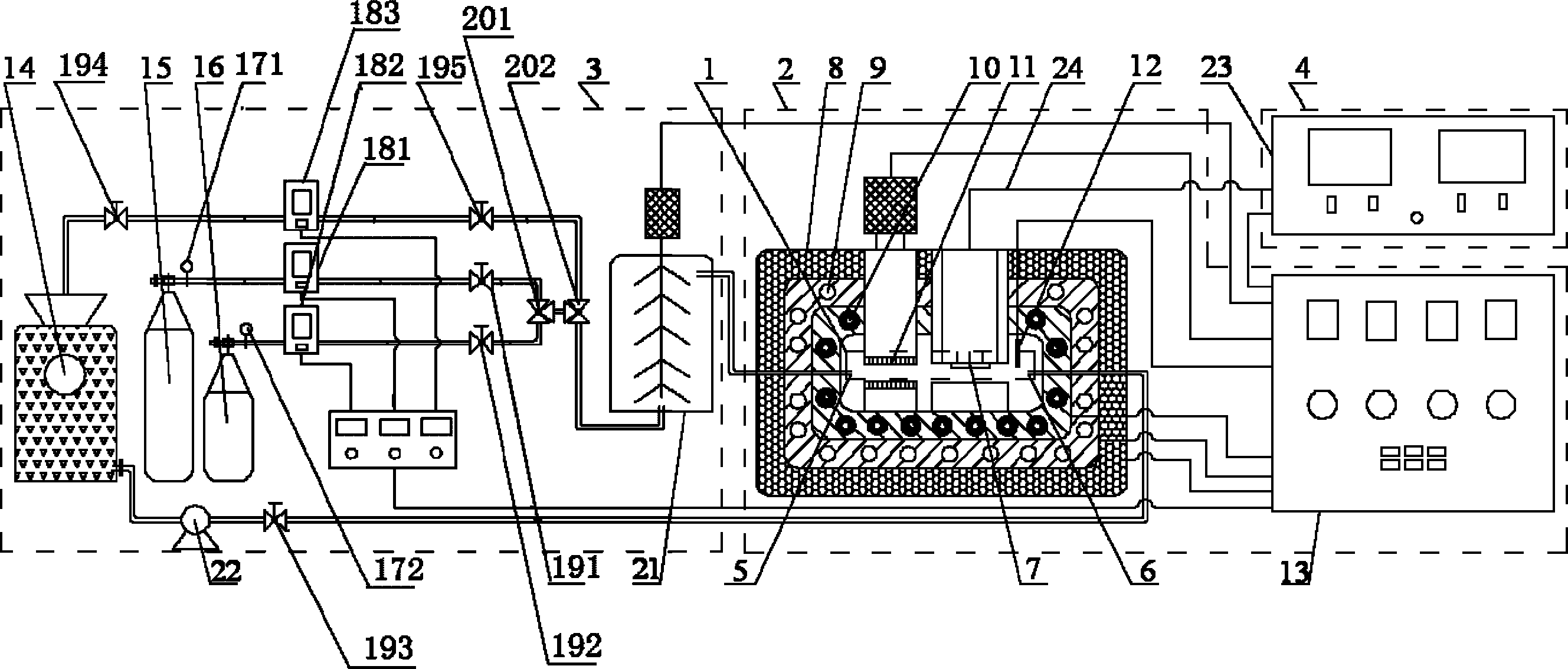

[0036] Such as figure 1 shown. A performance test device for a gas sensor, comprising: a test chamber 1 , a temperature and humidity control mechanism 2 , a circulation gas distribution mechanism 3 , and a gas sensitivity test mechanism 4 .

[0037] The test room 1 is used as a place for testing the performance of the gas sensor. The test room 1 includes a test area and a sample table 7, and the temperature and humidity control mechanism 2 is provided with an installation hole, and the sample table 7 is fixedly arranged in the installation hole and fixedly arranged directly above the vertical direction inside the test area; the test room 1 and The gas-sensitive testing mechanism 4 is connected by wires.

[0038] The temperature and humidity control mechanism 2 is used to control the test temperature and humidity of the test room. The temperature and humidity control mechanism 2 includes: heating tube layer, cooling tube layer, insulation layer 8, thermocouple 12, humidity re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com