High-voltage direct-current cable terminal using shielding cylinder

A high-voltage direct current, cable terminal technology, applied in the direction of the cable terminal, to achieve the effect of uniform field strength along the surface and increase the flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but these examples should not be construed as limiting the present invention.

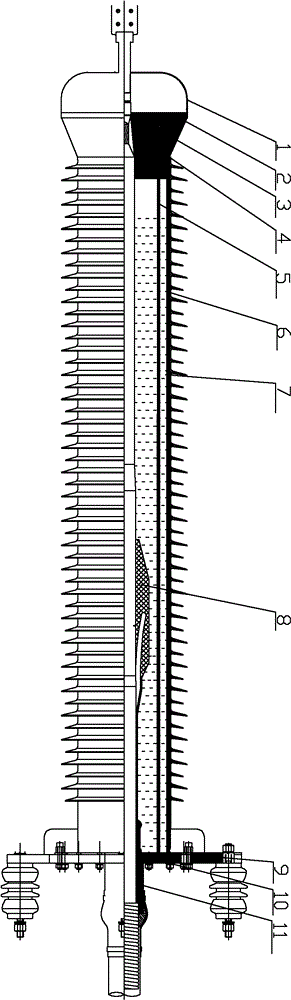

[0012] Description of reference symbols: 1 upper electrode, 2 upper flange, 3 epoxy parts, 4 shielding ring, 5 shielding cylinder, 6 epoxy composite sleeve (or porcelain sleeve), 7 insulating oil, 8 stress cone, 9 lower method Lan, 10 sealing ferrules, 11 tailpipes.

[0013] The embodiment of the present invention provides a high-voltage DC cable terminal with a shielding cylinder, including an upper electrode 1, an upper flange 2, an epoxy part 3, a shielding ring 4, a shielding cylinder 5, an epoxy composite sleeve (or porcelain sleeve ) 6. Insulating oil 7, stress cone 8, lower flange 9, sealing ring 10 and tailpipe 11.

[0014] On the cable at the high-voltage DC cable terminal, the upper electrode 1, the upper flange 2, the epoxy part 3, the stress cone 8, the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com