Plug for beverage container

A plug and container technology, applied in the direction of drinking utensils, etc., can solve the problems of difficult to identify the direction of the front, inconvenient loading and unloading operability, hindering drinking, etc., and achieve the effect of preventing forgetting to close the lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

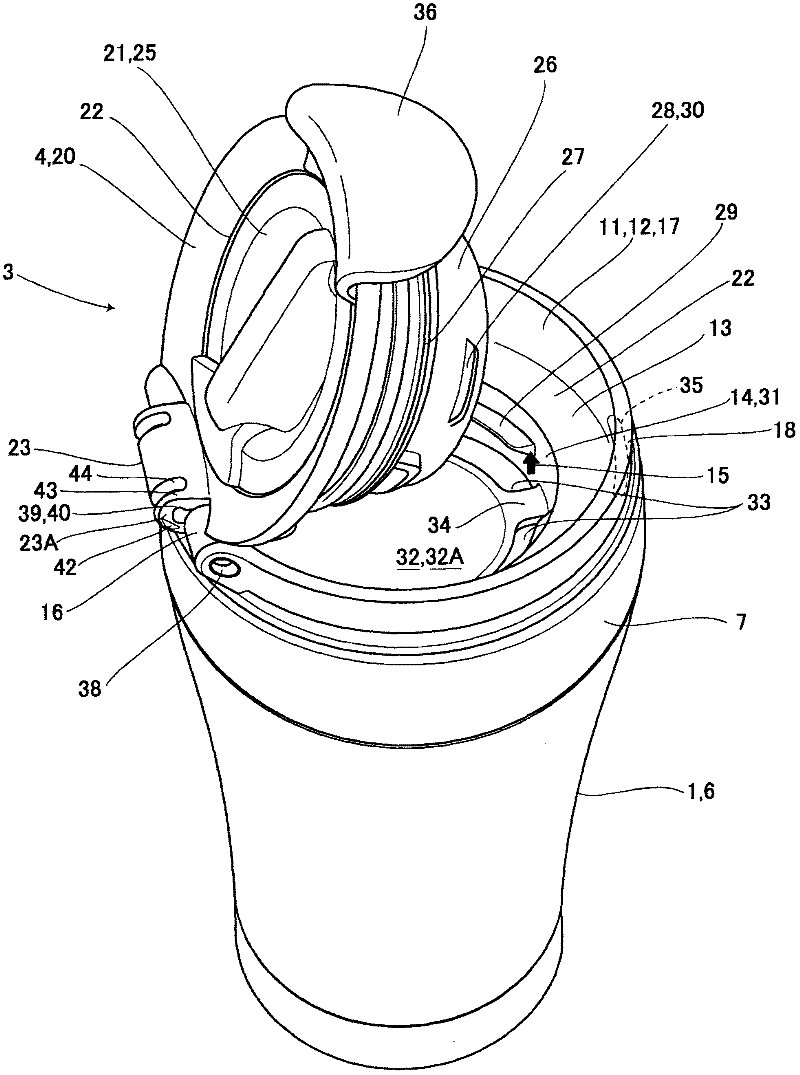

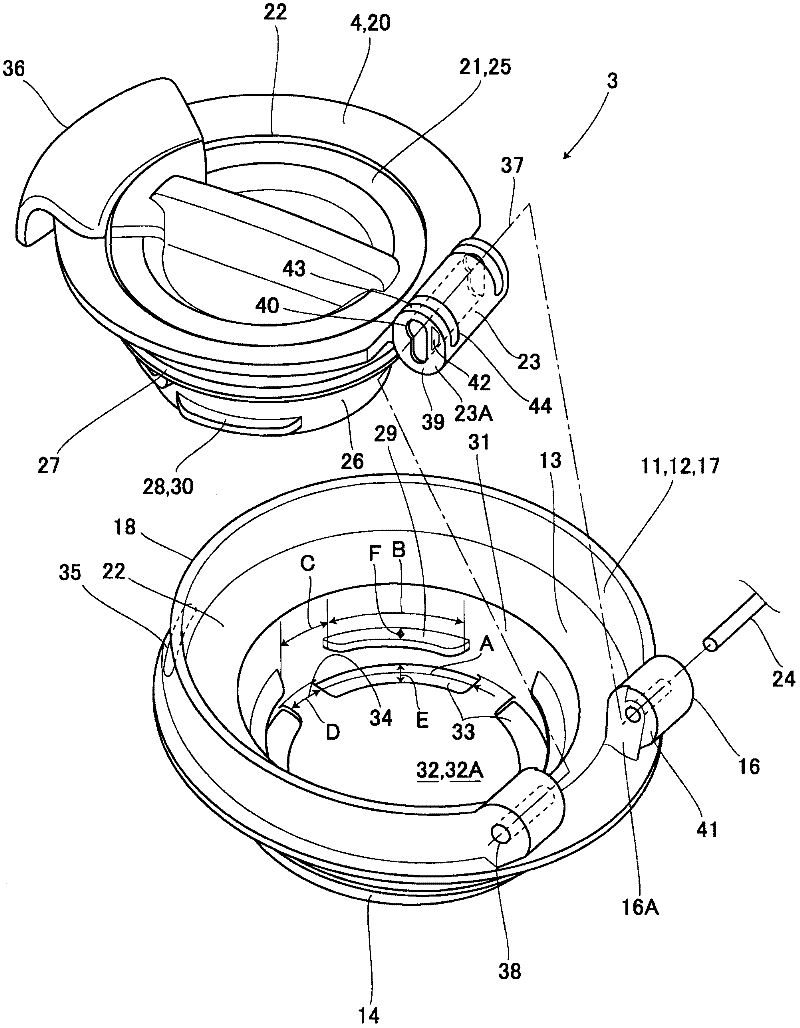

[0048] Such as Figure 1-9 As shown, the beverage container for containing water, coffee, tea or soft drink is covered with a plug body 3 mounted on the upper opening 2 of the container 1, and a lid body 4 is provided on the plug body 3 to open and close freely. The container 1 is provided with a bottomed cylindrical outer cylinder 6 on the outside of the bottomed cylindrical inner cylinder 5, and an edge member 7 is covered and installed on the upper edge of the main body joined by the mouth, and a vacuum is provided between the inner cylinder 5 and the outer cylinder 6. space8. Furthermore, a first internal thread 9 is formed on the inner periphery of the edge member 7 centering on the central axis 10 of the container 1 .

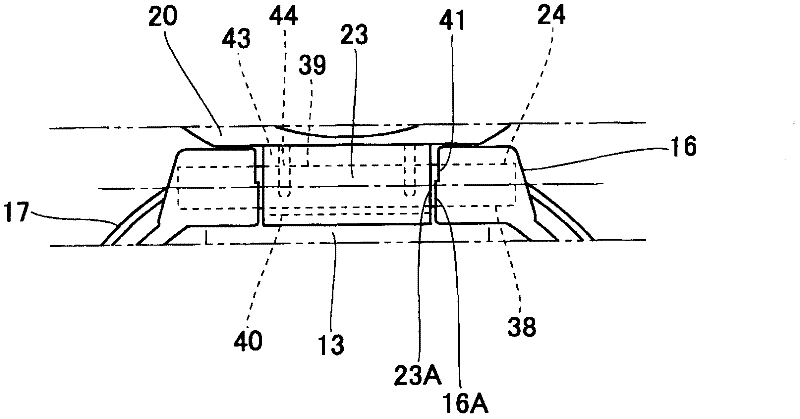

[0049] The plug main body 11 of the plug body 3 is made of synthetic resin, and has an upper cylindrical portion 12 coaxially covering and mounted on the upper opening portion 2 with the central axis 10 and connected to the upper cylindrical portion 12 t...

Embodiment 2

[0077] Figure 10 Example 2 is shown, and the same parts as those in the above-mentioned Example 1 are assigned the same symbols, and detailed description thereof will be omitted. In Embodiment 2, in the state where the ring member 20 and the plug body 3 are fixed integrally, the rotating member 21 advances and retreats relative to the ring member 20 in the up and down direction, and in the state where the rotating member 21 is locked on the plug body 11, Similar to Embodiment 1, the upper surface of the rotating member 21 and the upper surface of the ring member 20 are on the same plane, and when the locking of the rotating member 21 and the plug body 11 is released, the rotating member 21 is directed upward relative to the ring member 20. Prominent, the step 45' can be seen from the outside. Furthermore, the cover body 4 is hinged with the hinge receiving portion 16 as the base point, so that the plug body 3 is opened and closed.

[0078] Also in this second embodiment, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com