Measuring cup type metering mechanism without bin gate

A measuring cup and material gate technology, which is applied in the field of the measuring cup type measuring mechanism without material gate, can solve the problems such as difficulty in grasping the flatness of the upper turntable 4 and the lower turntable 5, wear of the metal surface, and increase of electric power of the motor, so as to save the cleaning workload, The effect of reducing material waste and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

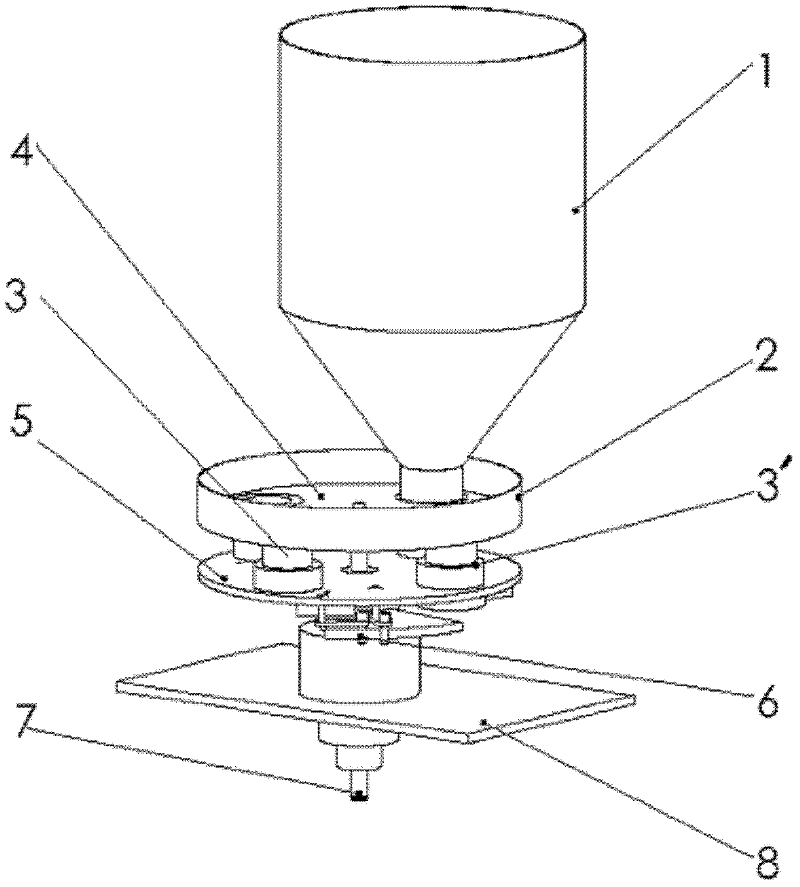

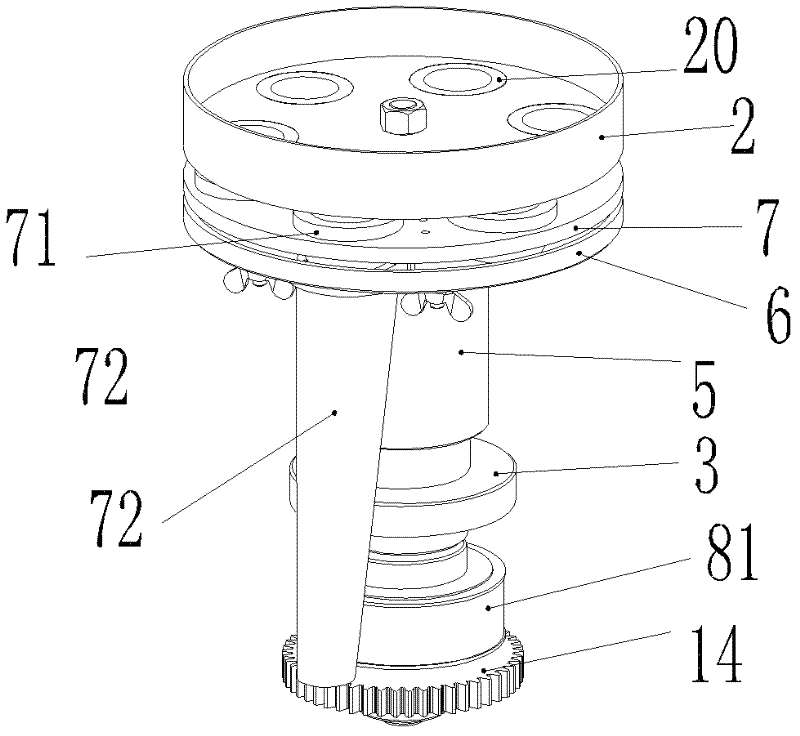

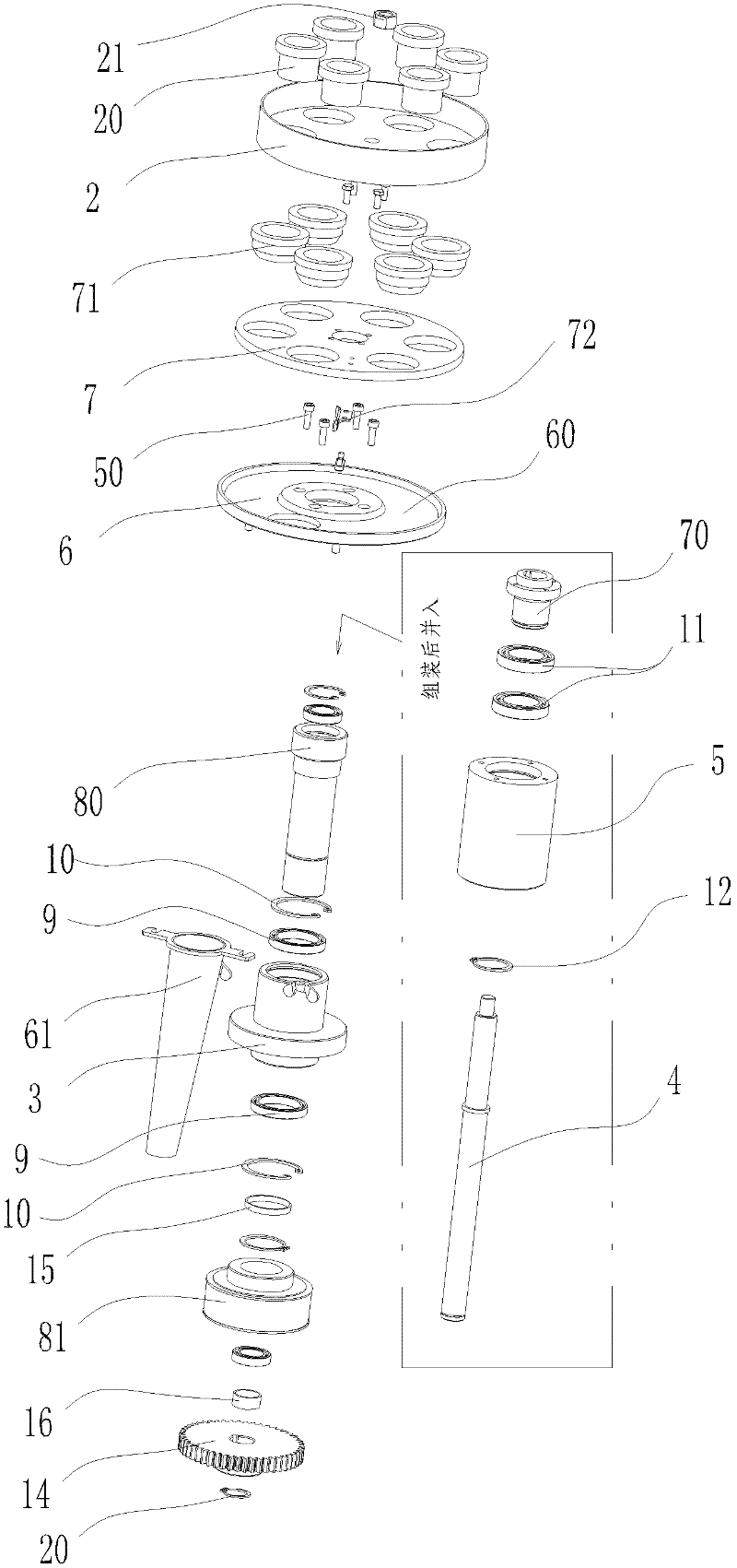

[0022] like Figure 2 to Figure 4 As shown, the non-material door measuring cup type metering mechanism includes a mounting frame 1, a driving motor (not shown in the figure), a material disc 2, an axle seat 3 and a metering disk spindle 4, and the axle seat 3 is fixed on the mounting frame 1, and the metering disk The main shaft 4 is sleeved on the shaft seat 3 and driven by the drive motor to rotate. The material disc 2 used to accept the material is installed on the top of the metering disc main shaft 4 through the nut 21; The upper sleeve 5 of the upper sleeve 5, the top of the upper sleeve 5 is fixed on the blanking plate 6 sleeved on the upper part of the main shaft 4 of the metering disc through the hexagon socket head screw 50; 7. The middle plate 7 is fixed on the upper end of the middle plate base 70 sleeved on the upper part of the metering disc main shaft 4, and the lower end of the middle plate base 70 is fixed in the center cavity of the upper sleeve 5 and the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com