Shutter having snap-in type blade

A technology of blinds and blades, which is applied in the field of blinds, can solve the problems of low installation efficiency, high installation difficulty, and inability to connect frames, and achieve the effects of improving installation efficiency, improving installation convenience, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

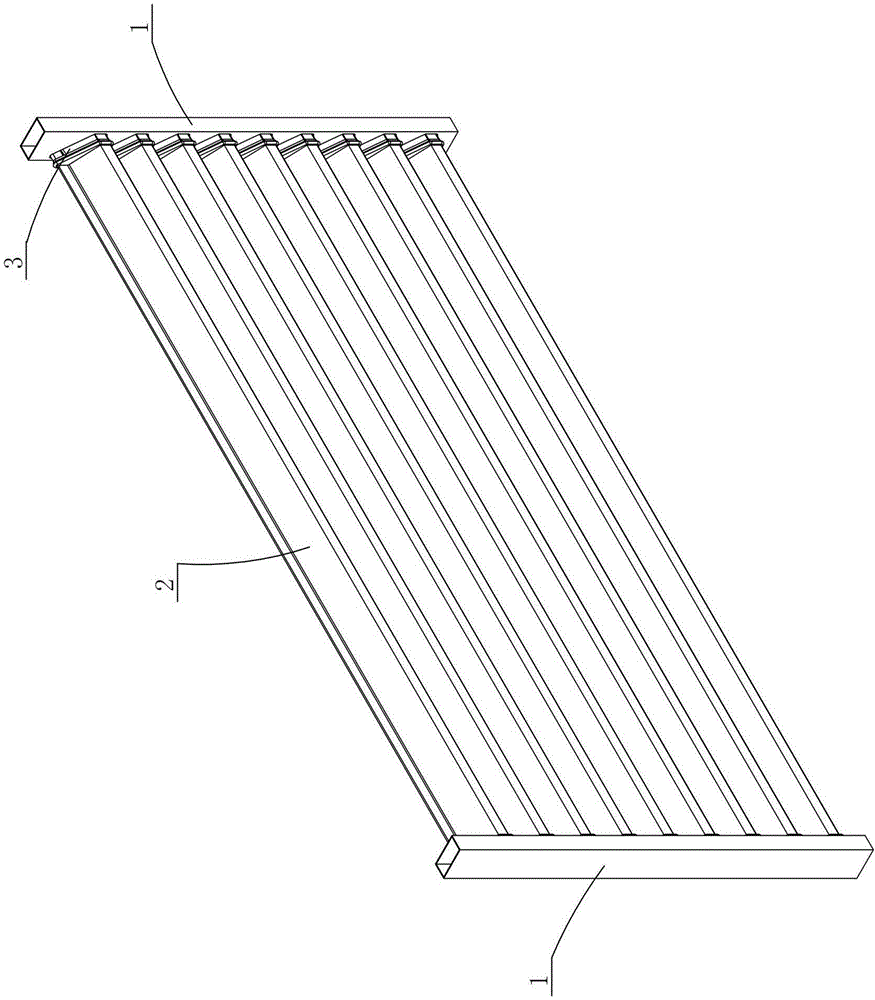

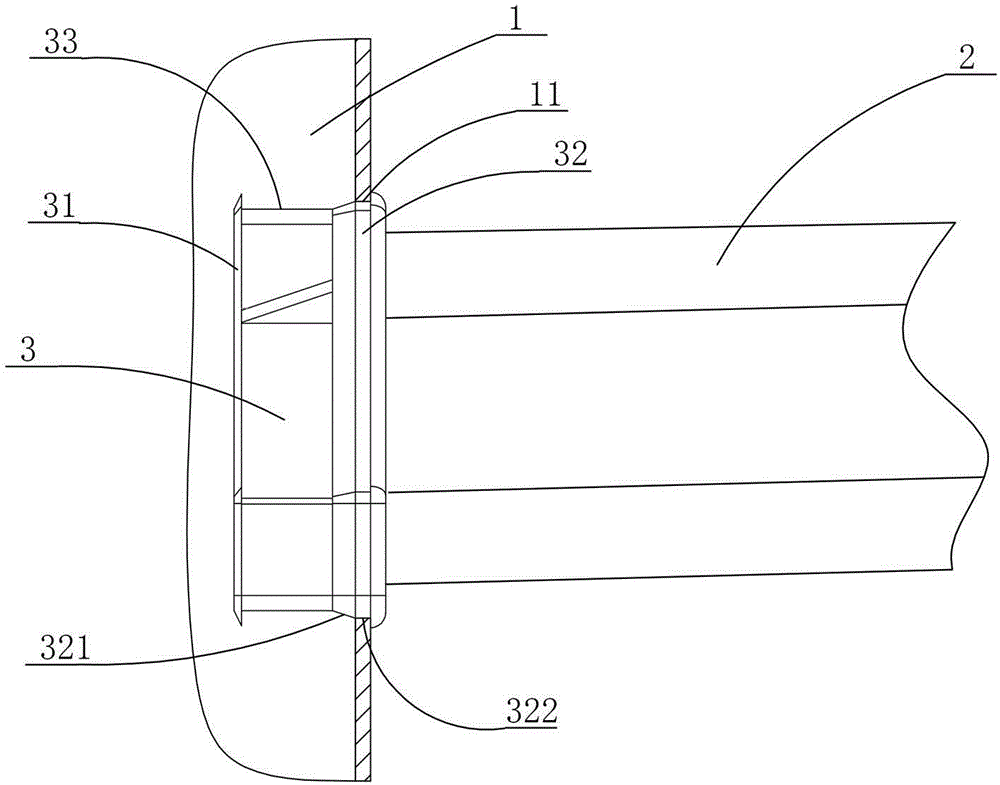

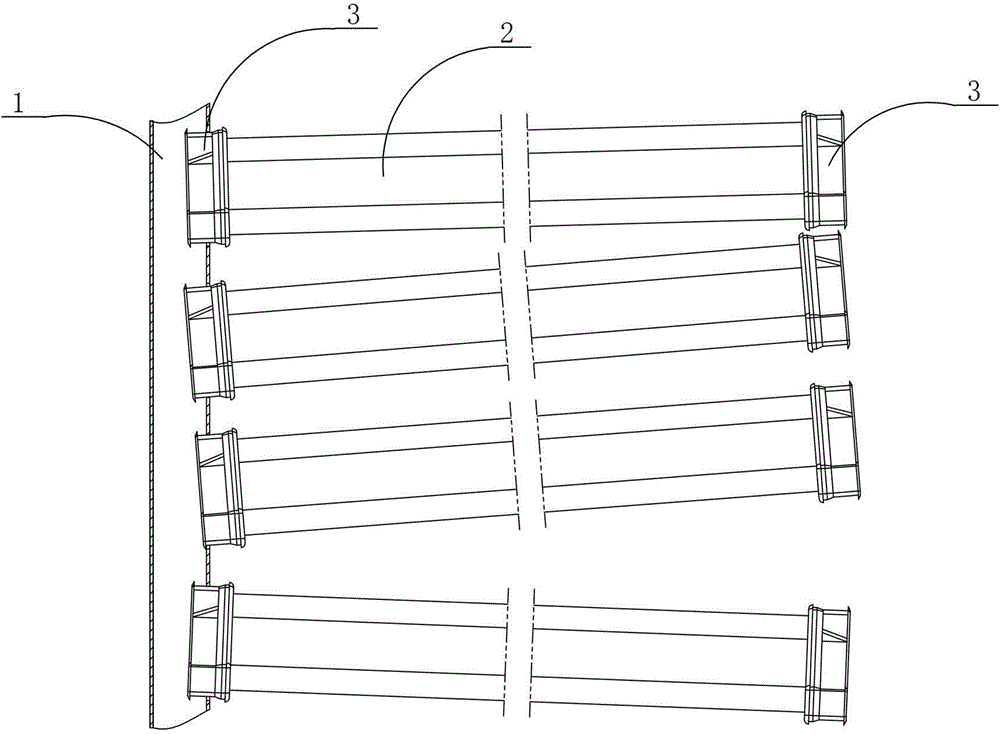

[0020] Figure 1 to Figure 5 It shows an embodiment of a louver with buckle-in blades of the present invention. The louver of the present invention includes a frame 1, blades 2 and blade fixing pads 3, and both ends of the blade 2 are respectively inserted into a blade fixing pad 3. The blade fixing pad 3 is inserted in the blade installation hole 11 on the frame 1, and the end of the blade fixing pad 3 and the blade installation hole 11 is provided with an elastic rib 31, and the end of the blade fixing pad 3 and the blade 2 is provided with a Tight buckle section 32, a recessed adjustment gap section 33 is provided between the elastic rib 31 and the tight buckle section 32, after the elastic rib 31 is squeezed and buckled into the blade installation hole 11, the elastic rib 31 can block the blade The inside of the mounting hole 11 is to prevent the blade fixing pad 3 from naturally protruding from the blade mounting hole 11. When installing, the blade fixing pad 3 at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com