Temperature calibration method of laser gyro inertia measurement unit

A technology of inertial measurement unit and laser gyroscope, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of large approximation error of temperature error model, affecting the measurement accuracy of laser gyroscope and accelerometer, and not completely separated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

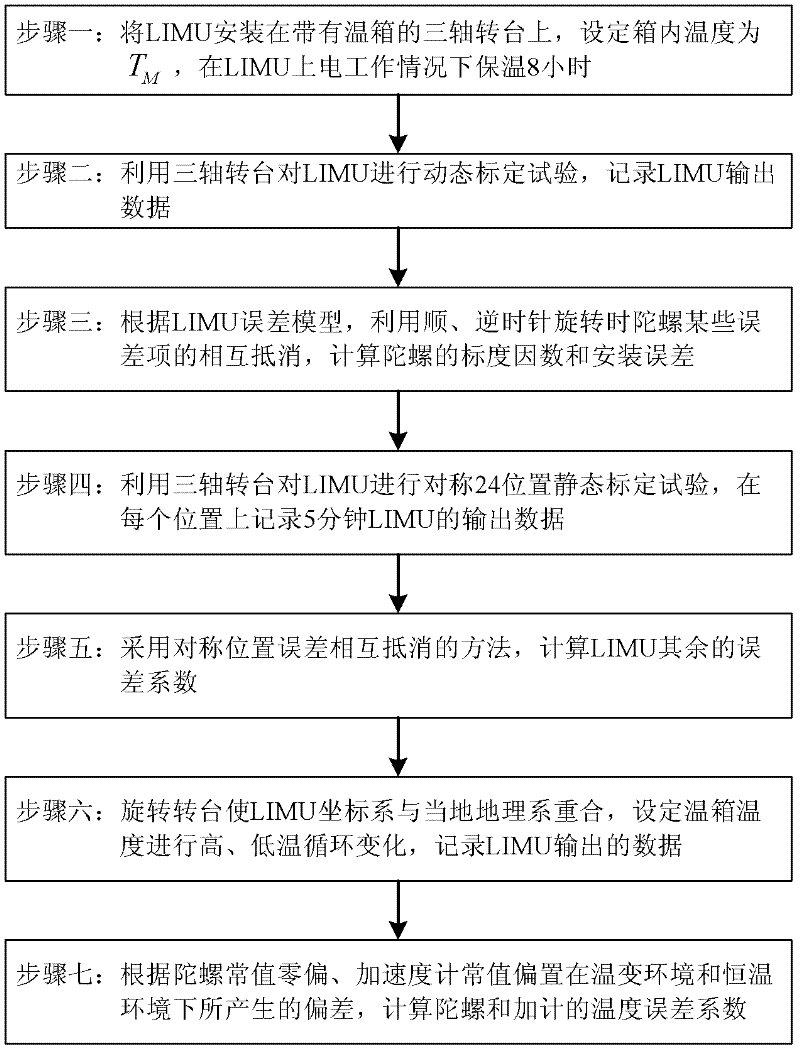

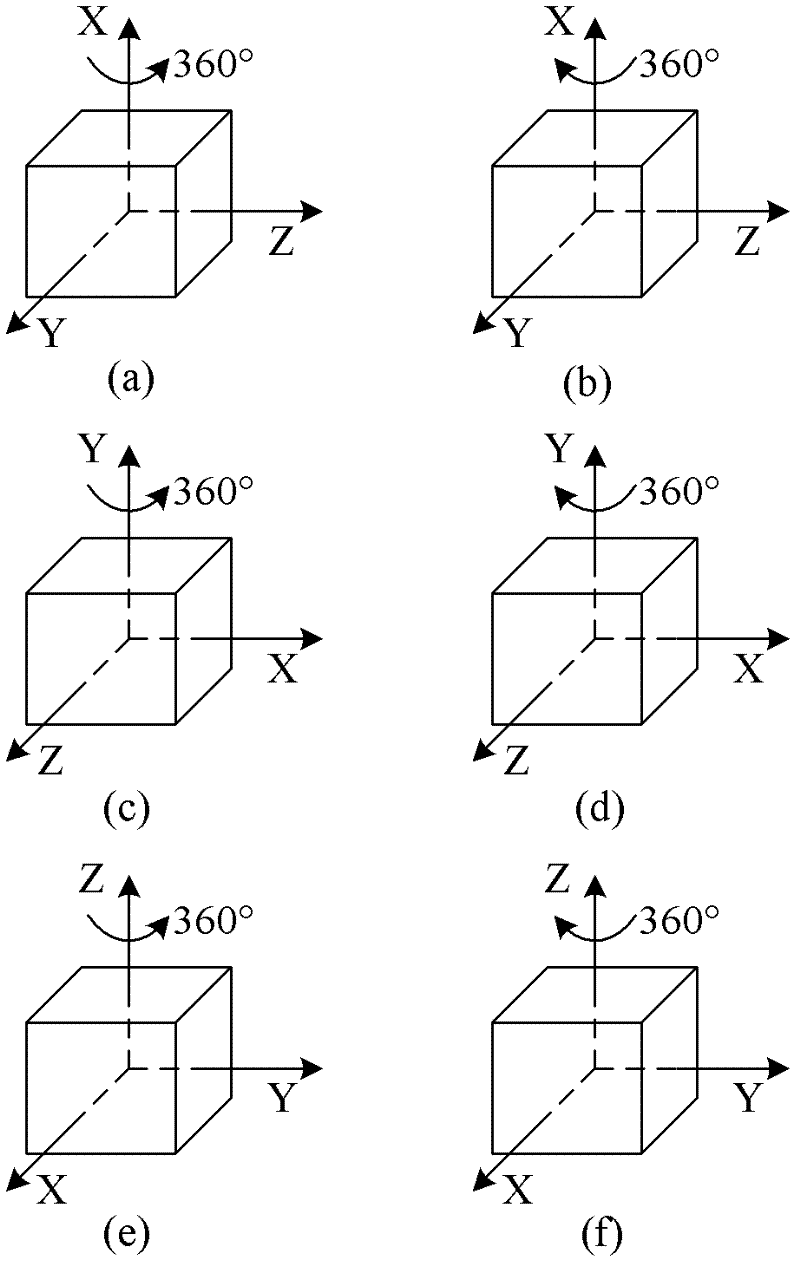

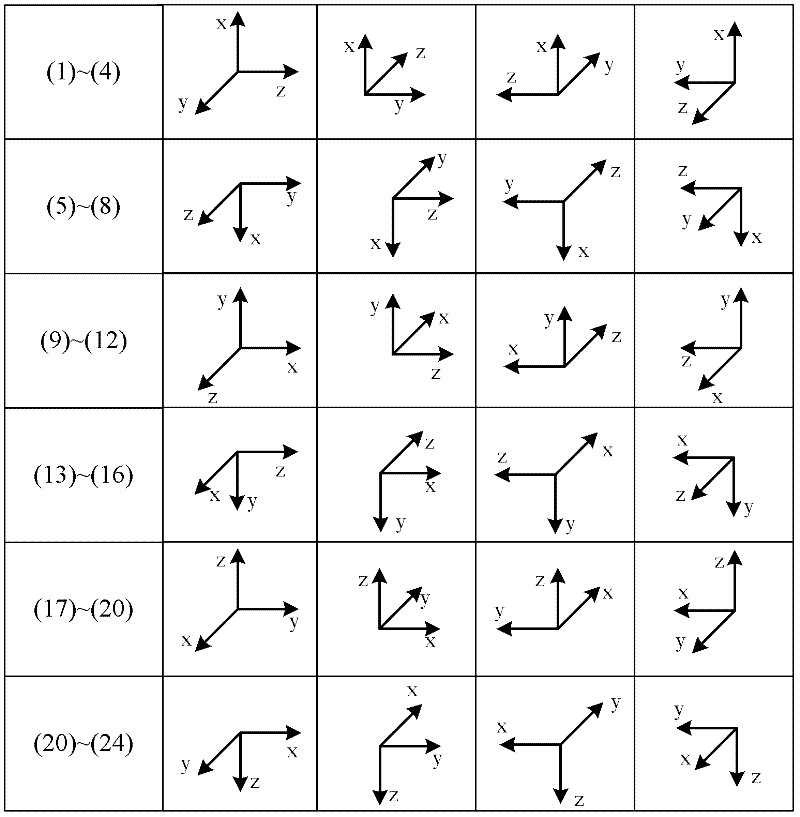

[0023]The present invention adopts the strategy of separating and calibrating the system inherent error and temperature error, through the measure of long-term heat preservation at a certain temperature point, the LIMU reaches the overall thermal balance, and adopts the calibration method combining dynamic rotation and static 24 positions to accurately calibrate the The system inherent error coefficients such as gyro scaling factor, gyro constant value drift, accelerometer scaling factor and accelerometer constant value bias, etc., and then use the inherent error coefficient of LIMU at this temperature point to conduct high and low temperature cycle tests on LIMU, The temperature error coefficients of gyroscope constant value drift and accelerometer constant value bias are further calibrated, including 30 temperature correlation coefficients, including primary temperature coefficient, secondary temperature coefficient, temperature gradient coefficient and temperature change rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com