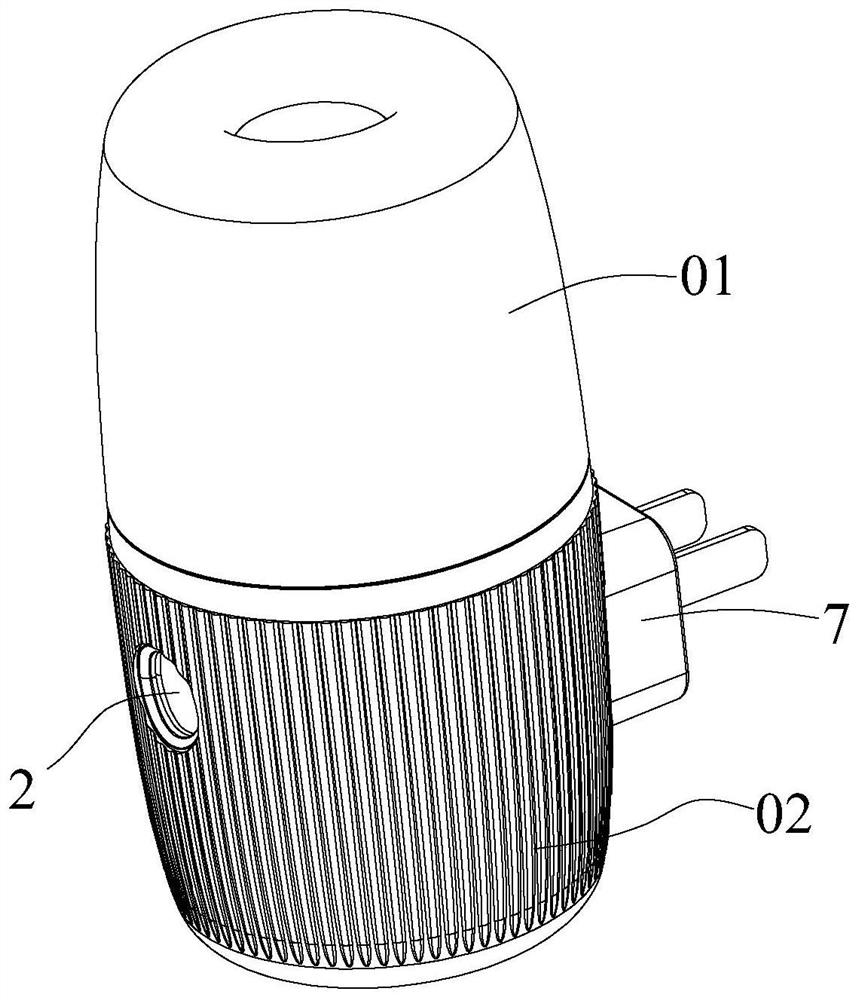

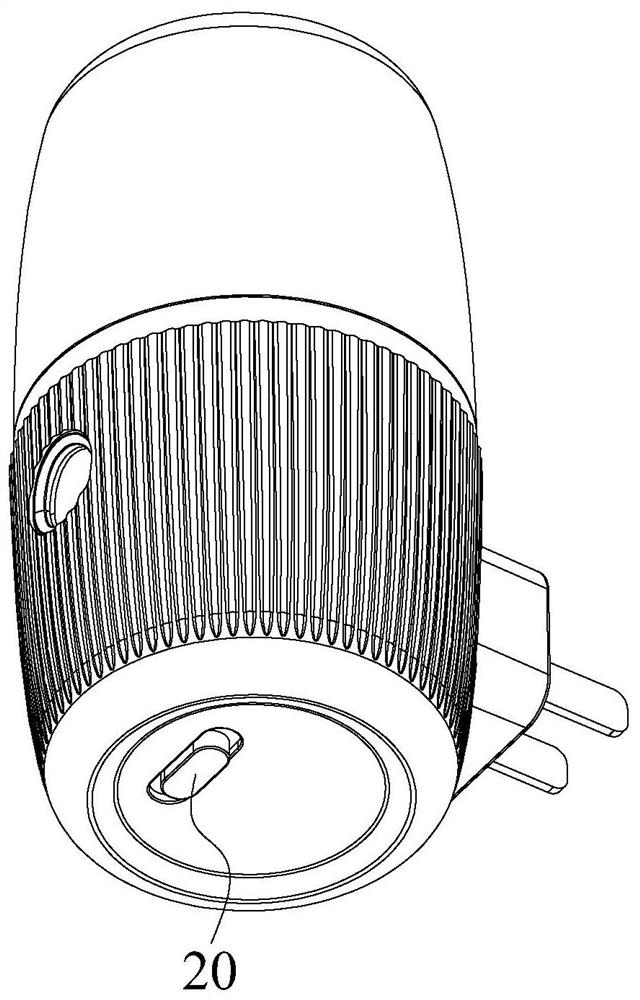

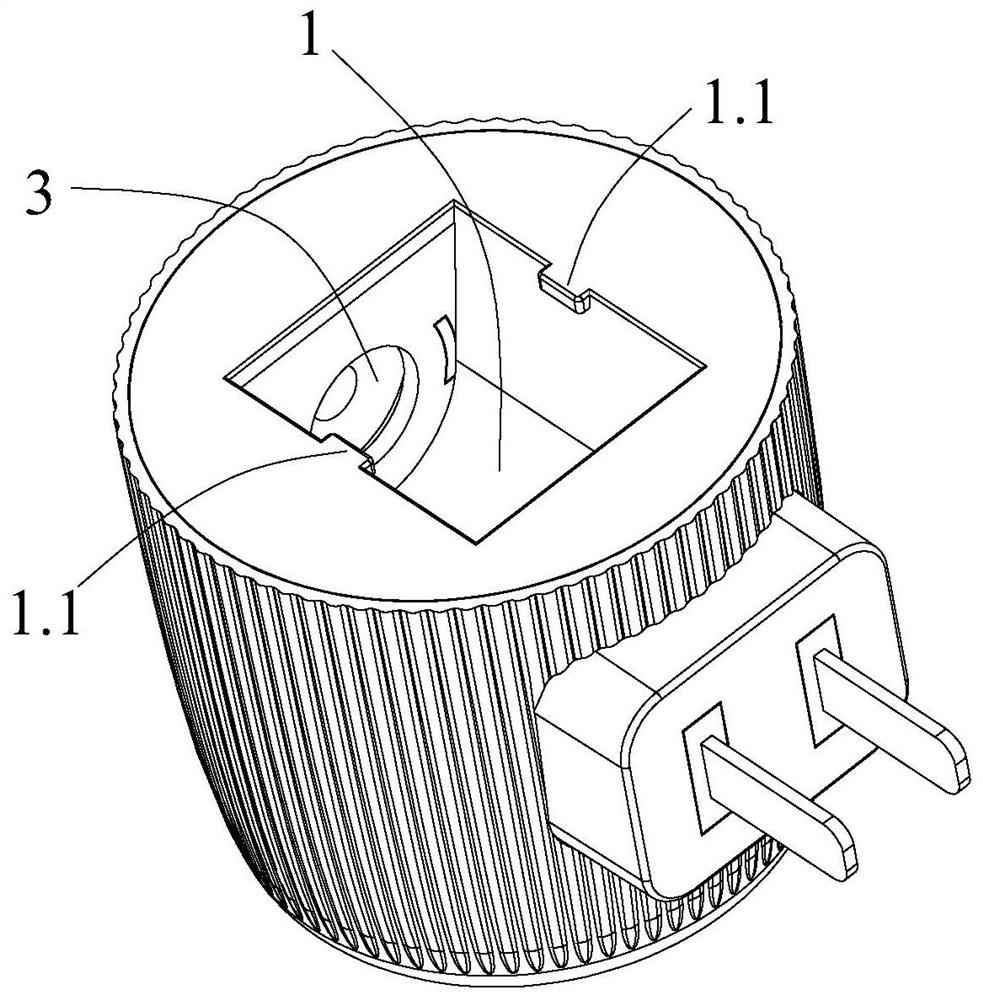

Spraying mosquito dispeller

A technology of mosquito repellent and atomizer, which is applied in the direction of animal repellent, device for catching or killing insects, application, etc. It can solve the problem of uneven volatilization of active ingredients in electric heating liquid mosquito repellent incense, affecting the effect of repelling mosquitoes, and repelling mosquitoes. fluid loss etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0033] In the description of the invention, it is to be noted that the terms "outer end", "inner side wall", "bottom", "lower end", "upper", "middle", "outer side wall", or positional relationship In order to facilitate the description of the present invention and simplified description, not to describe the present invention and simplified description, rather than indicating or implying that the device or component must have a specific orientation, and therefore cannot be It is understood that the limitation of the invention.

[0034] In the description of the present invention, it is to be described in that, unless otherwise expressly specified and defined, the term "connection" should be understood, for example, may be a fixed connection, or a detachable connection, or integrally connected; It is a mechanical connection or an electrical connection;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com