Wireless control automatic releaser

A wireless control, automatic release technology, applied in the testing of machine/structural components, connecting components, circuits, etc., can solve the problems of easy aging, troublesome safety, easy icing, etc., to improve the safety distance factor and eliminate inconvenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

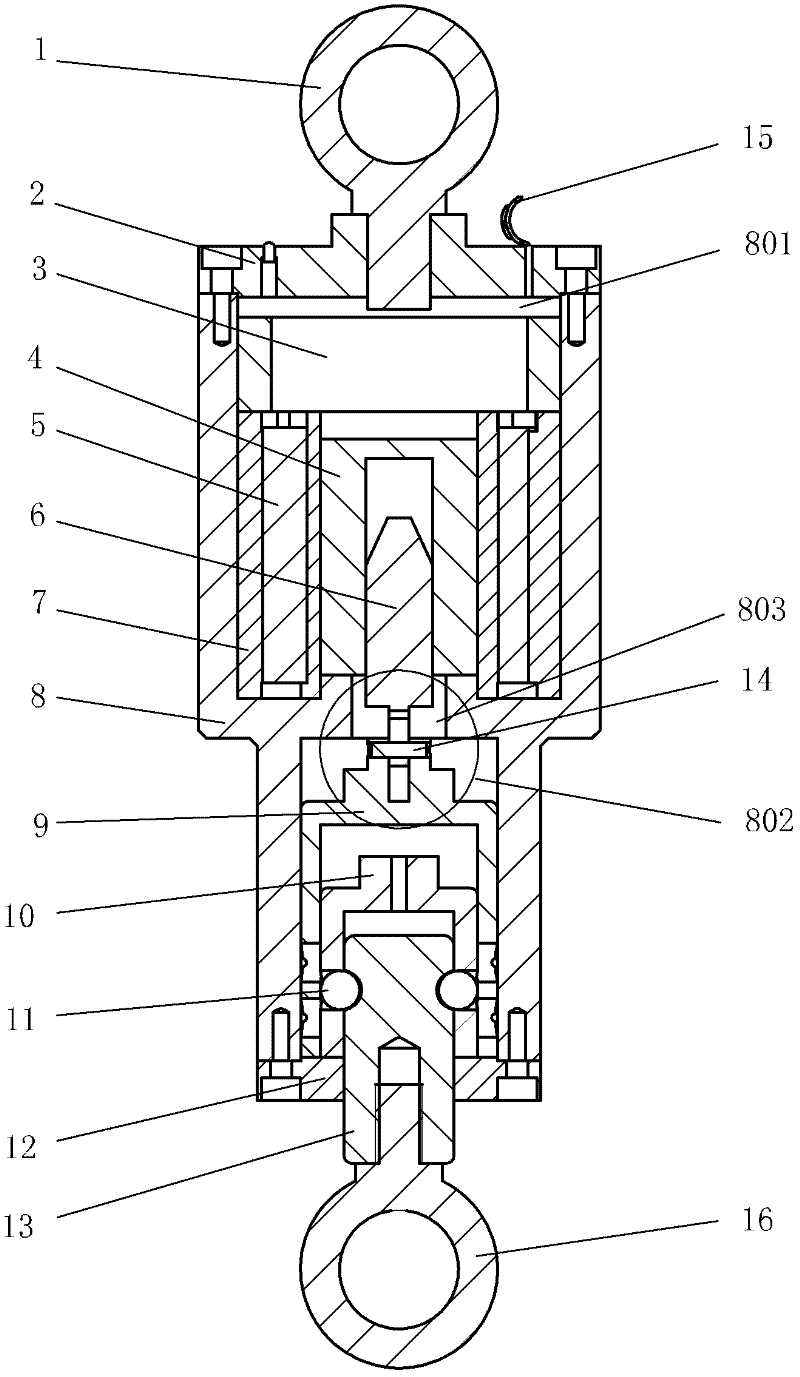

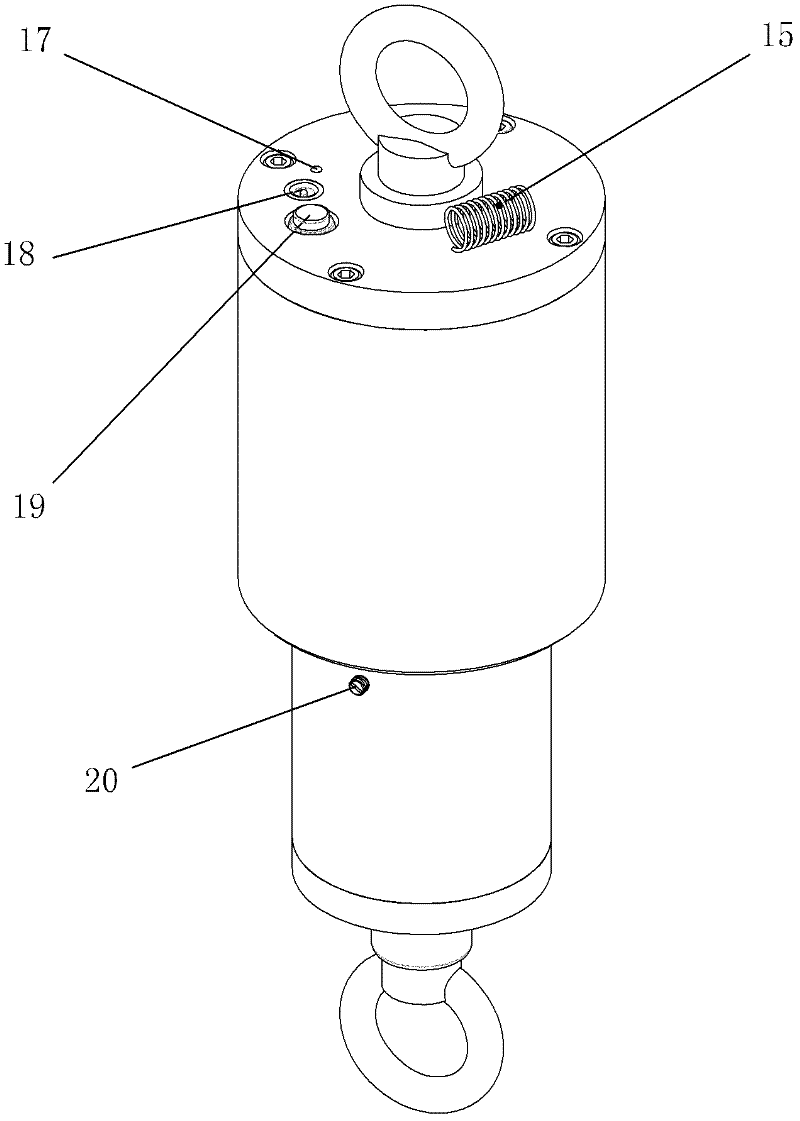

[0037] refer to figure 1 , figure 2 and image 3 , The automatic release device of the present invention includes a metal shell 8, a rechargeable battery 5, a wireless control system, an electromagnetic mechanism and a release mechanism. The wireless control system includes a remote controller, a control switch 19 , a wireless control module 3 and an antenna 21 . The electromagnetic mechanism includes an electromagnet 4 and an iron core 6 . The release mechanism includes a release sleeve 9 , a movable sleeve 10 and a release pin 13 .

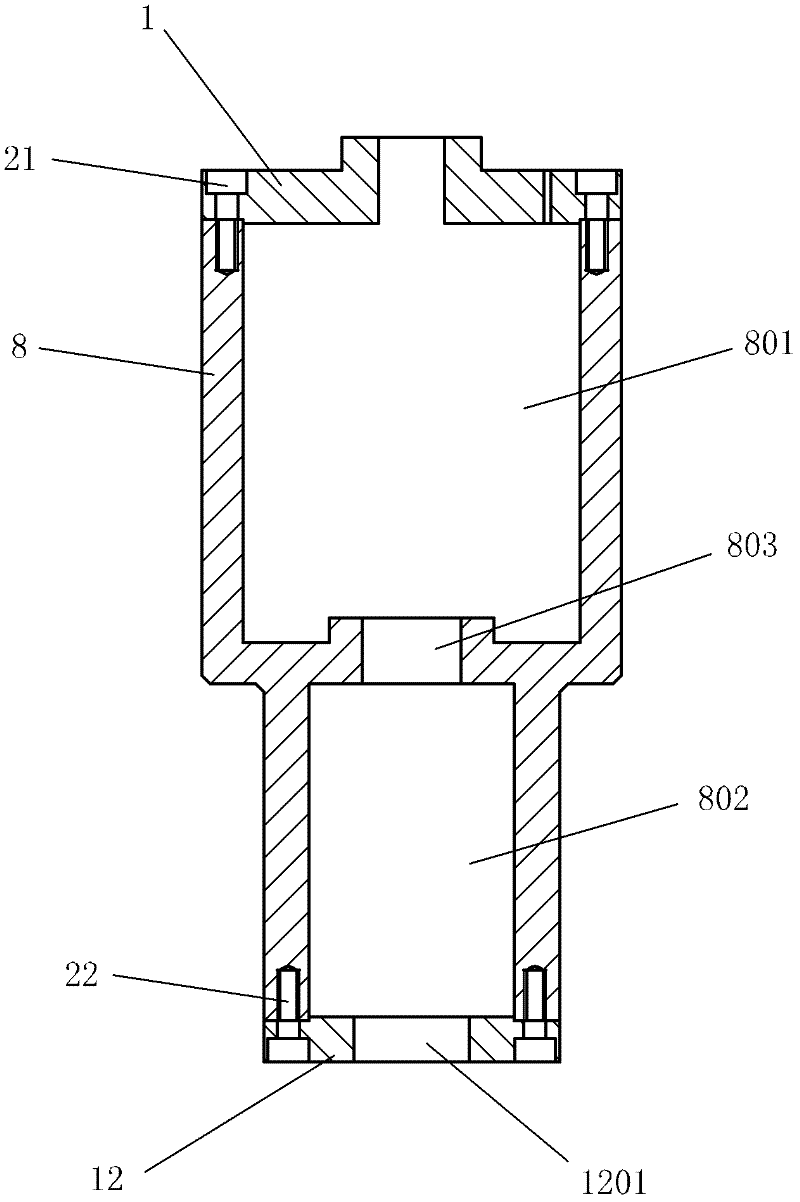

[0038] The metal shell 8 is a cylindrical structure with an upper cavity 801 and a lower cavity 802, the diameter of the upper cavity 801 is larger than the diameter of the lower cavity 802, and the centerlines of the upper and lower cavities are on the same straight line , and communicated through the central hole 803. The top and bottom of the metal shell 8 are respectively provided with a top cover 2 and a bottom cover 12 .

[0039] An...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap