Hydraulic fatigue test system of connecting rod

A fatigue test, hydraulic technology, applied in the direction of machine gear/transmission mechanism testing, using repetitive force/pulse force to test the strength of materials, etc. The effect of reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] 1. The overall composition of the engine connecting rod hydraulic fatigue test system

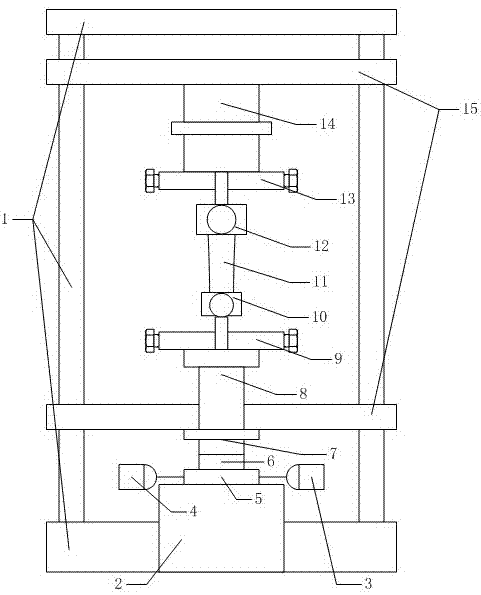

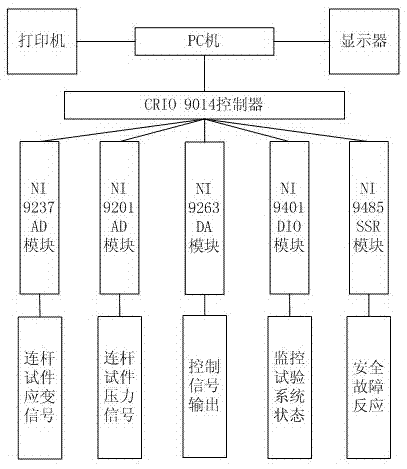

[0020] The test system consists of two components, the test bench and the control system. According to the functions, the test bench includes: pumping station mechanism, hydraulic loading mechanism, test bench body, clamping and bearing mechanism.

[0021] test system such as figure 1 shown.

[0022] 2. Introduction of each part of the test system

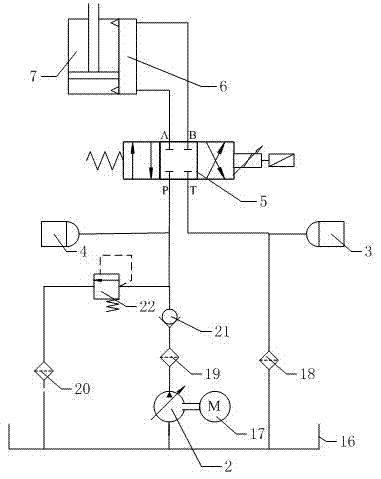

[0023] Pump station mechanism

[0024] like figure 2 As shown, the pumping station mechanism includes a hydraulic pumping station 2, an oil tank 16 and a motor 17. The main function of the pumping station mechanism is to provide hydraulic power for the system and provide hydraulic oil with a certain pressure and a certain flow rate to the hydraulic loading mechanism. The hydraulic pump station 2 of this test system is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com