Nondestructive diagnosis of battery performance

A battery and battery pack technology, applied in the direction of measuring electricity, measuring electrical variables, measuring resistance/reactance/impedance, etc., to achieve the effect of accurately determining performance and measuring accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

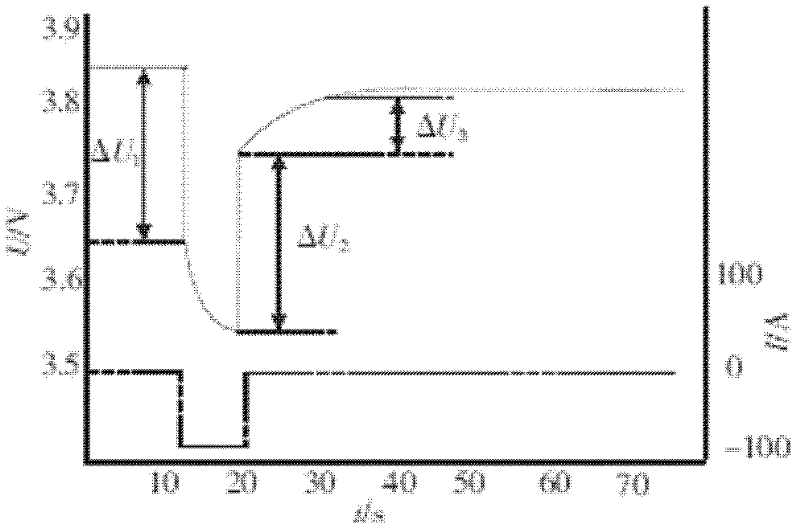

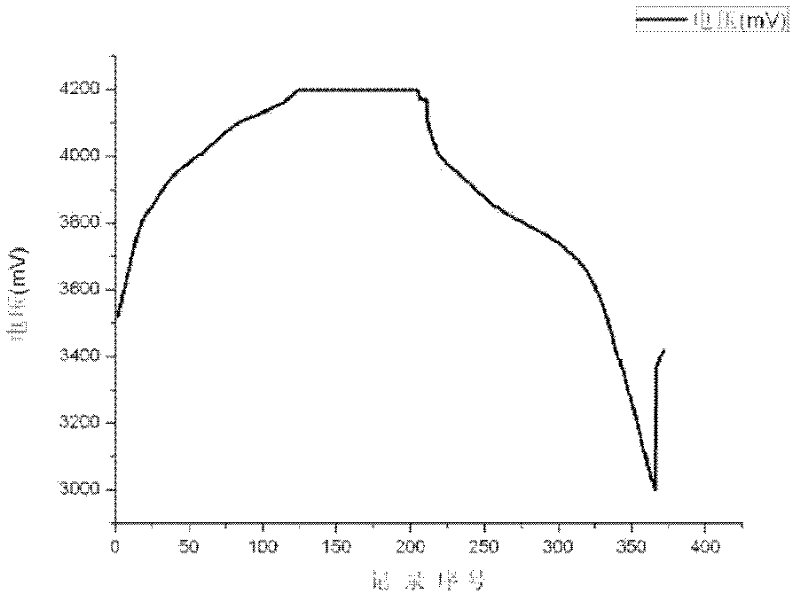

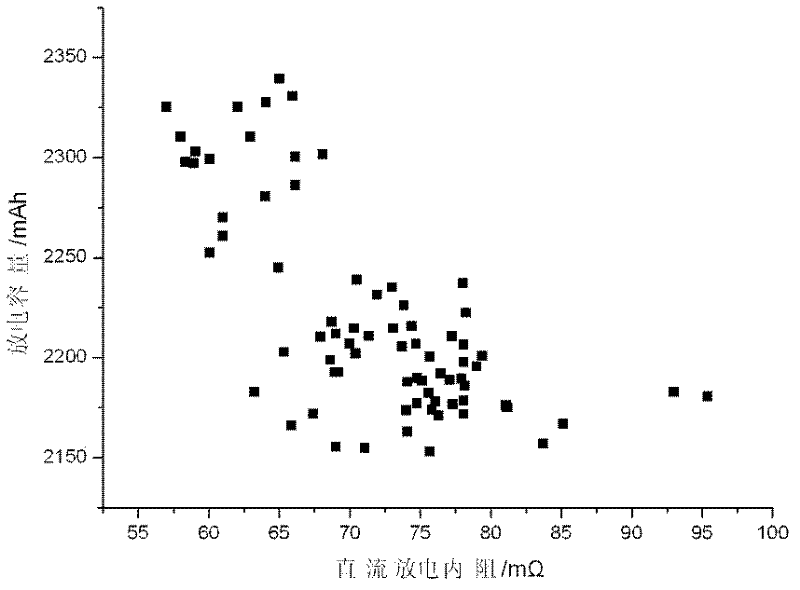

[0021] Use the lithium-ion battery inspection device to conduct a charge-discharge test for a certain type of lithium-ion, and record the current and voltage values during the charge-discharge process, take one of the complete charge-discharge processes, and record the serial number (representing the test time) as the X-axis , the battery voltage is plotted on the Y axis. From the figure, we can see the change of voltage with the charge and discharge time. It is easy to see that there are sudden changes at the beginning and end of discharge. Refer to the attached figure 2 . Calculate the change value of voltage sudden drop at the beginning of discharge, take the instantaneous value of current at the start of discharge, divide the change value of voltage sudden drop by the instantaneous value of current, and obtain the DC discharge internal resistance of the battery. Count the internal resistance of 20 DC discharges, see the attached image 3 , take the upper middle value o...

Embodiment 2

[0023] Select batteries with different internal resistances for cycle tests, take the second complete charge and discharge process of each battery cycle test, and record the sudden change value of the discharge start voltage and the instantaneous value of the current. Calculate the DC discharge internal resistance of each battery, and compare the relationship between the DC discharge internal resistance and the AC test internal resistance. And take the internal resistance obtained by the AC test as the X axis, and the DC discharge internal resistance as the Y axis to draw a graph, and the attached Figure 4 . From attached Figure 4 It can be seen that the DC discharge internal resistance is basically consistent with the change in the battery internal resistance obtained by the AC test, indicating that the estimation of the battery performance by the DC discharge internal resistance is consistent with the estimation of the battery performance by the AC discharge internal resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com