Circular polarizer with flexible and variable rotation and braking angles

A circular polarizer and angle technology, applied in the direction of electrical components, antennas, etc., can solve the problems of difficult control of the installation position accuracy of the proximity switch, groove position error, and the electrical connector is easy to be exposed to rain, etc., to achieve the rotation and braking angle. The effect of being flexible, solving sealing and corrosion resistance problems, and reducing the complexity of manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

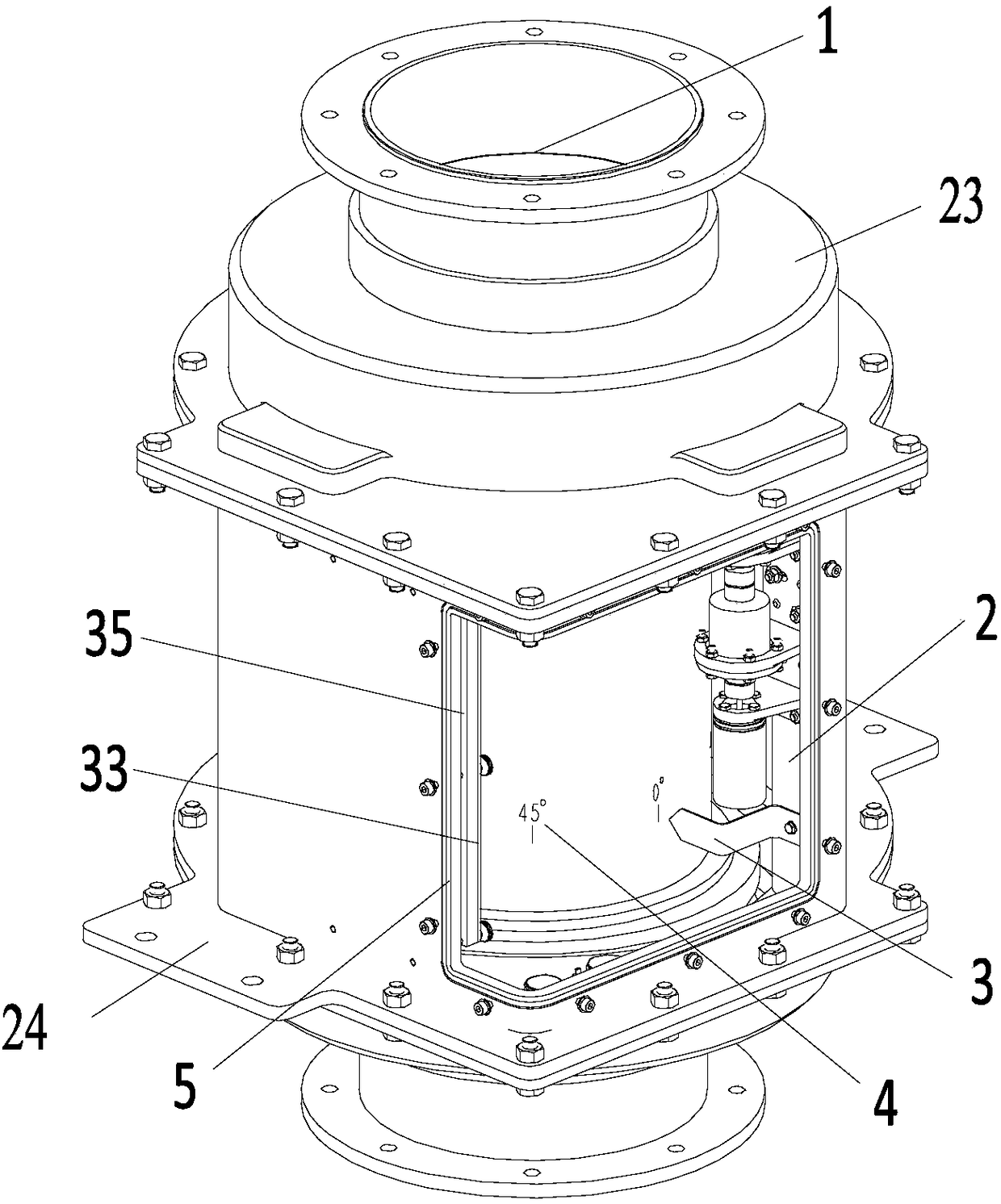

[0062] Encoder 9 is model 906-28XZ42, encoder coupling 10 and encoder gearbox coupling 12 are coupling SFC-005SA2-3B-3B-M, motor 19 is model Maxon RE25 Among them, 339152 has a rated speed of 10900rpm, and the motor gearbox 20 uses Maxon GP 32A series 166167, and its reduction ratio is 86.

[0063] The reduction ratio of encoder reduction box 11 is 5.2:1. Encoder combination gear 14 has 20 teeth and a modulus of 2.5 mm, waveguide gear 15 has 104 teeth and a modulus of 2.5 mm, so the reduction ratio of the large and small gears is 20 / 104=1 / 5.2. Therefore, the rotational angular velocity of the waveguide assembly 1 is always synchronized with the encoder 9 , which facilitates the encoder 9 to interpret the operating state of the waveguide assembly 1 in real time.

[0064] The rated power of the motor 19 is 20W, the rated torque is 28.8mNm, and the rated speed is 10900rpm.

[0065] The reduction ratio of the gearbox 20 is 86, and the maximum continuous output torque is 4.5Nm. ...

Embodiment approach 2

[0070]Open 5 parallel waist-shaped through holes on the motor support 21, pass these waist-shaped through holes with bolts, drive device 2 including the motor support 21 and the aluminum shell 25 are connected and fixed together (note that the bolts are light It is enough to lightly tighten the belt, do not fix it completely, so as to facilitate the next step of clearance adjustment). Utilizing the swimming adjustment ability of these waist-shaped holes, when hitting the motor support 21 back and forth with a hammer, the gap between the motor combination gear 22 on the driving device 2 and the waveguide gear 15 on the action actuator can be adjusted, and the gap can be adjusted to The proper size can neither cause the drive to be stuck because it is too small or too tight, nor can the gap be too large. In order to avoid large gear backlash and low transmission accuracy, it is more appropriate to control this gap at about 0.01mm. After adjusting the gap properly, tighten the m...

Embodiment approach 3

[0072] Five parallel waist-shaped through holes are opened on the encoder support 13, and bolts pass through these waist-shaped through holes to connect and fix the angle measuring mechanism including the encoder support 13 and the aluminum housing 25 together (note The bolts can be lightly tightened, and should not be completely fixed, so as to facilitate the clearance adjustment in the next step). Utilizing the swimming adjustment ability of these waist-shaped holes, when hitting the encoder support 13 back and forth with a hammer, the gap between the encoder combination gear 14 on the angle measurement mechanism and the waveguide gear 15 on the action actuator can be adjusted, and the gap can be adjusted. Adjust to an appropriate size, neither the drive will be stuck due to too small or too tight, nor the backlash of the gears will be too large due to the gap. In order to avoid large gear backlash and low transmission accuracy, it is more appropriate to control this gap at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com