Connecting structure of charging interface

A charging interface and connection structure technology, which is applied in the direction of connecting, joining/disconnecting connected parts, two-part connecting device, etc., can solve the problems of increasing the difficulty of plugging, high manufacturing cost, and no guide mechanism, etc., to achieve The effect of prolonging the service life, eliminating potential safety hazards, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

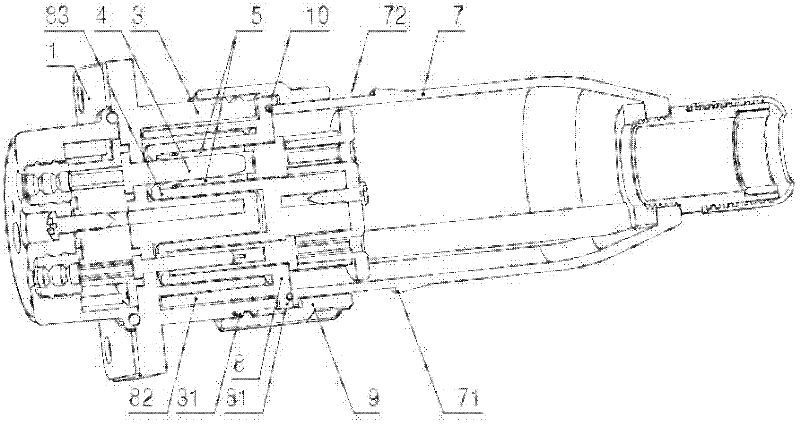

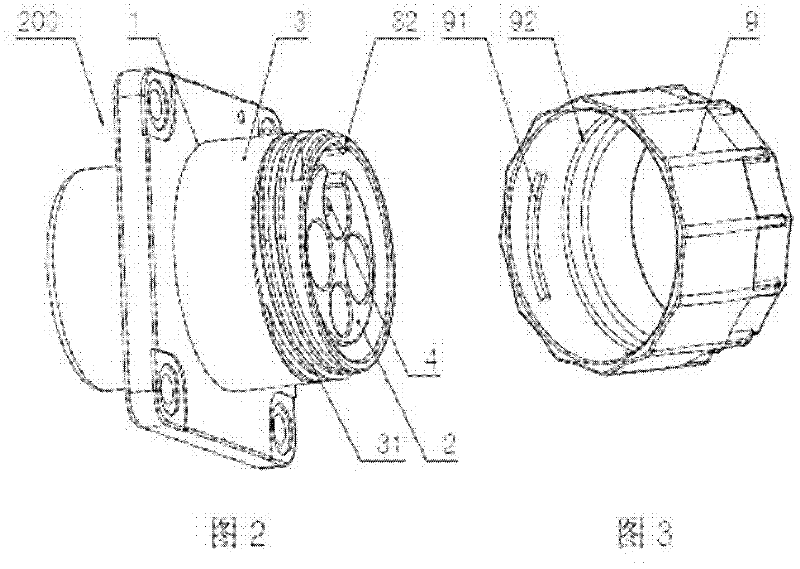

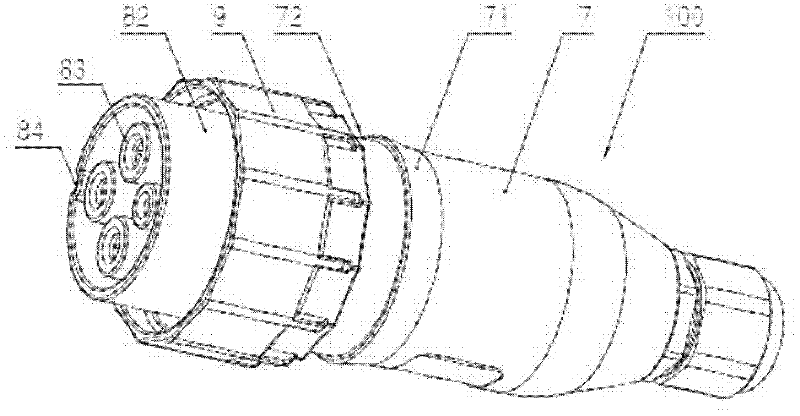

[0018] Such as figure 1 , figure 2 and image 3 As shown, the connection structure of the charging interface of the present invention includes a plug 100 and a socket 200, and the socket 200 includes: a socket housing 1 and a socket body mounting seat 2 arranged in the socket housing 1, and the connection of the socket housing 1 The end is provided with a circular socket barrel 3, and the plug 100 includes: a plug body mounting base 8 and a plug housing 7 connected to the plug body mounting base 8, and a movable sleeve on the plug housing 7 and the plug body mounting base 8 Pull-proof cover 9, such as Figure 4 As shown, the inner wall of the pull-out prevention cover 9 is sequentially provided with a circumferential internal connecting thread 91 and a limiting boss 92 along the pull-out direction, and the plug body mounting seat 8 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com