Materials and processes for making luggage

A suitcase and box body technology, applied in the suitcase field, can solve the problems of luggage weight limitation, low reliability of damage resistance, actual weight limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

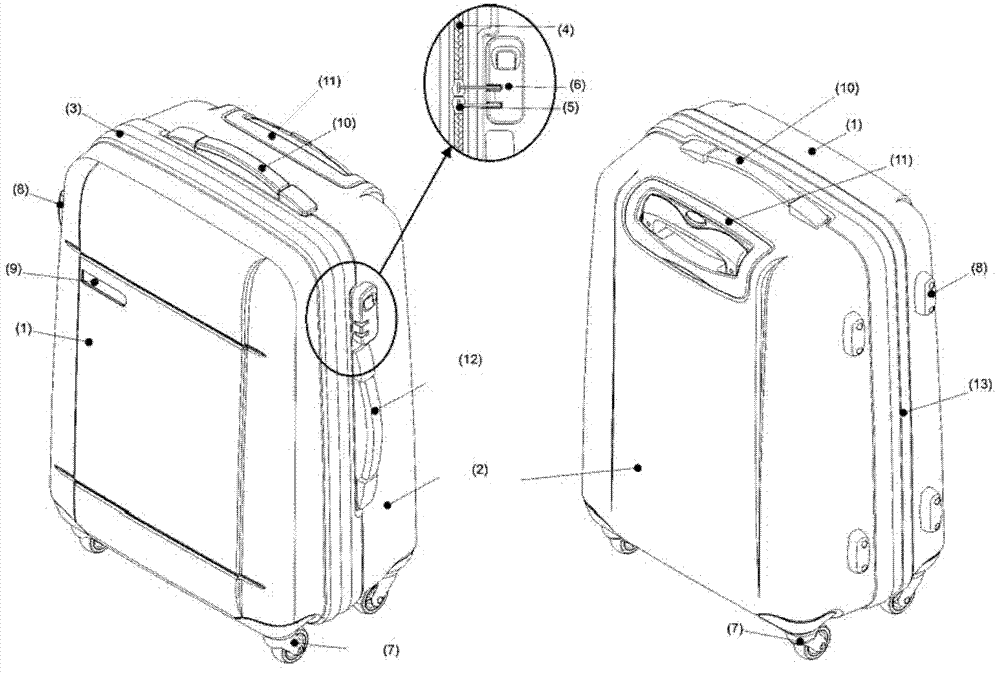

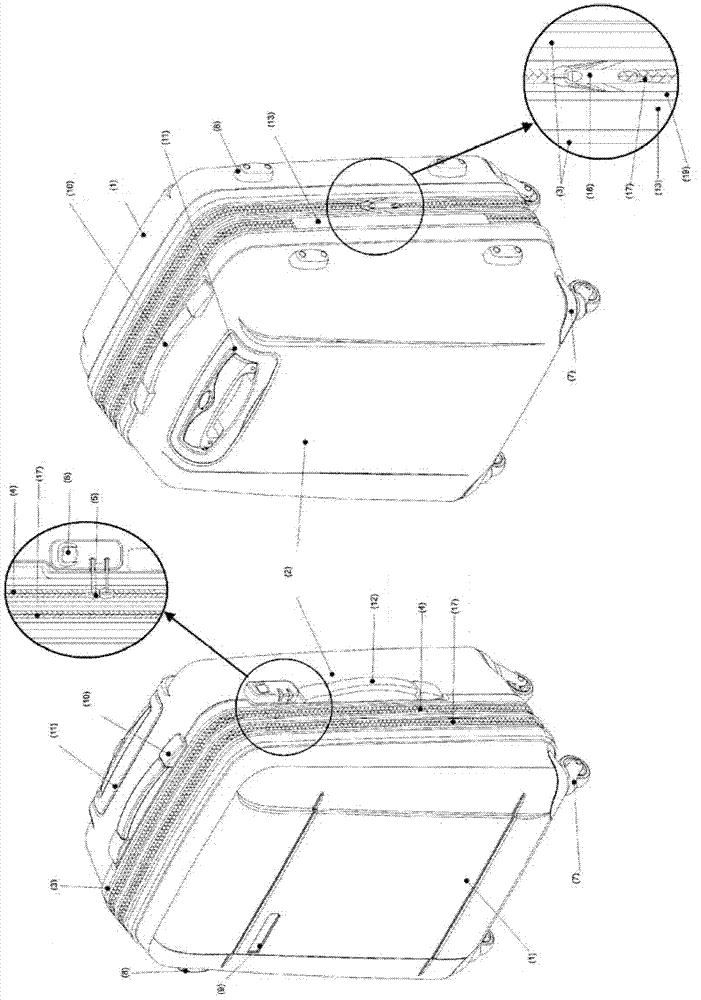

[0032] The present invention relates to the construction of luggage such as suitcases for travellers.

[0033] It is an object of the present invention to provide a "semi-rigid" suitcase construction which avoids at least some of the problems arising from the use of hard and soft cases of known construction.

[0034] For the purposes of this application, a "semi-rigid" box is considered as such because the top bottom side and end walls are not as easily pierced by a blade or needle as boxes of known soft box construction.

[0035] A further object is to provide a suitcase whose appearance differs from that of the mere standard rectangular block construction of suitcases.

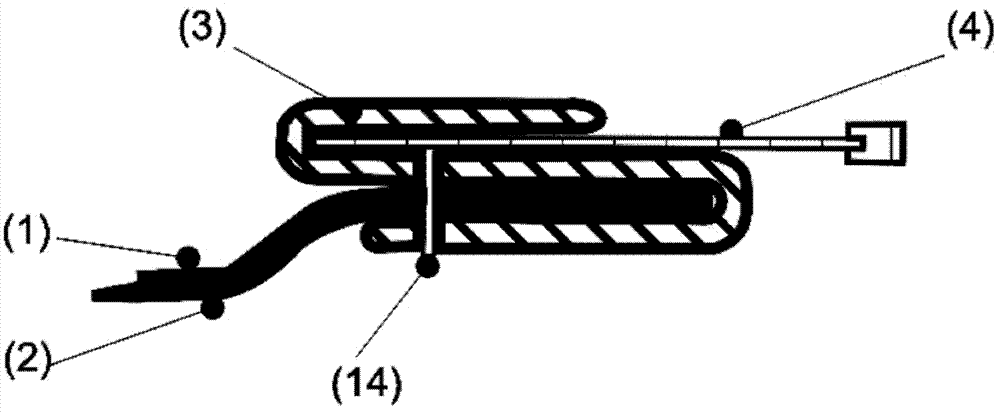

[0036] In general according to a first aspect of the invention there is provided a structure such as figure 1 The method of a rigid suitcase shown, comprising forming a shaped base portion 2 and a shaped lid portion 1 from a plastics material having features to retain the parts in their assigned shape, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com