Expansible center

A technology of tip and mold base, which is applied in the field of expandable tip, can solve the problems of high coaxiality and verticality, tolerance of drawing shape and position, inconvenient loading and unloading, etc., and achieve high running precision, small vibration, and low required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

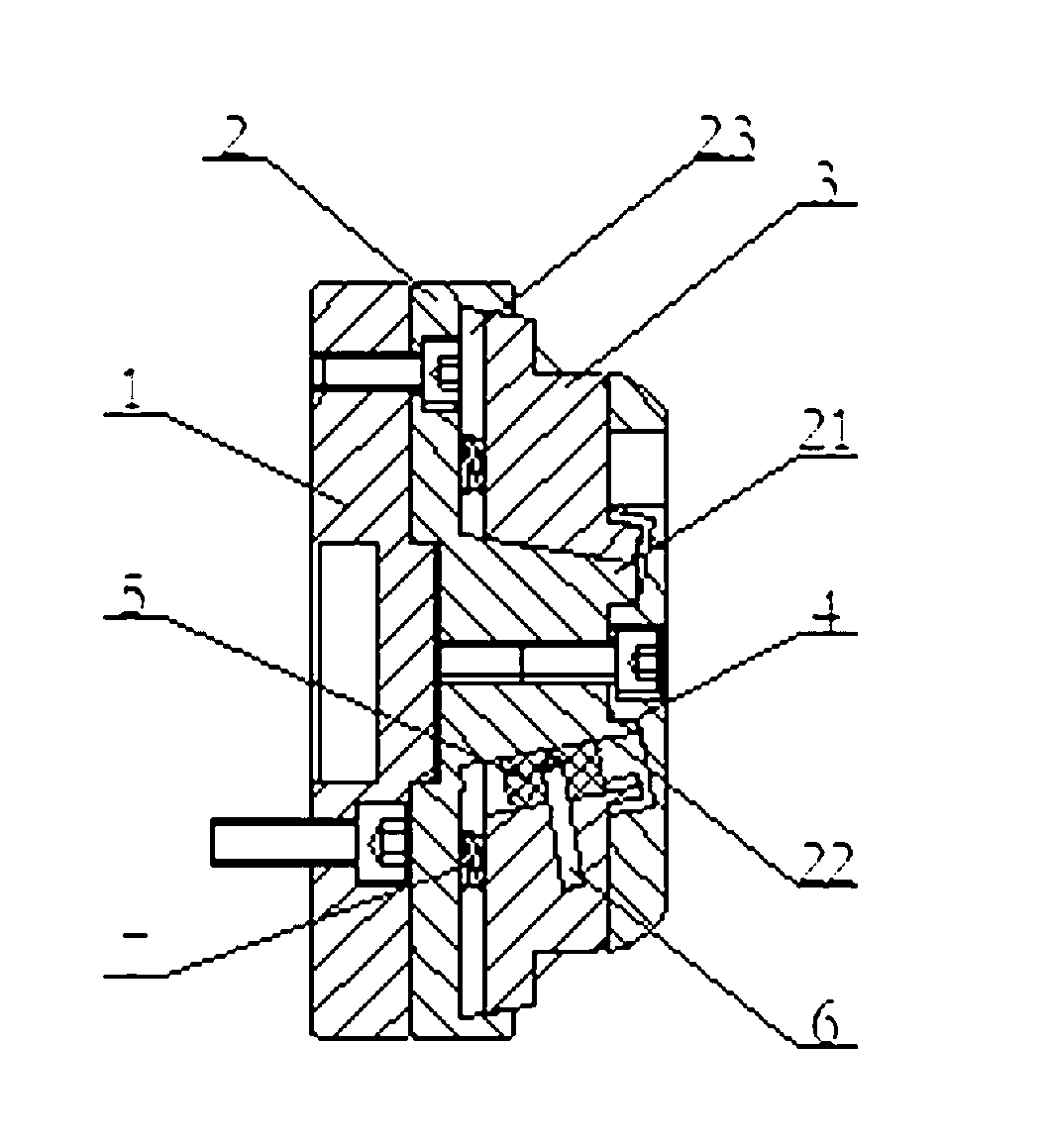

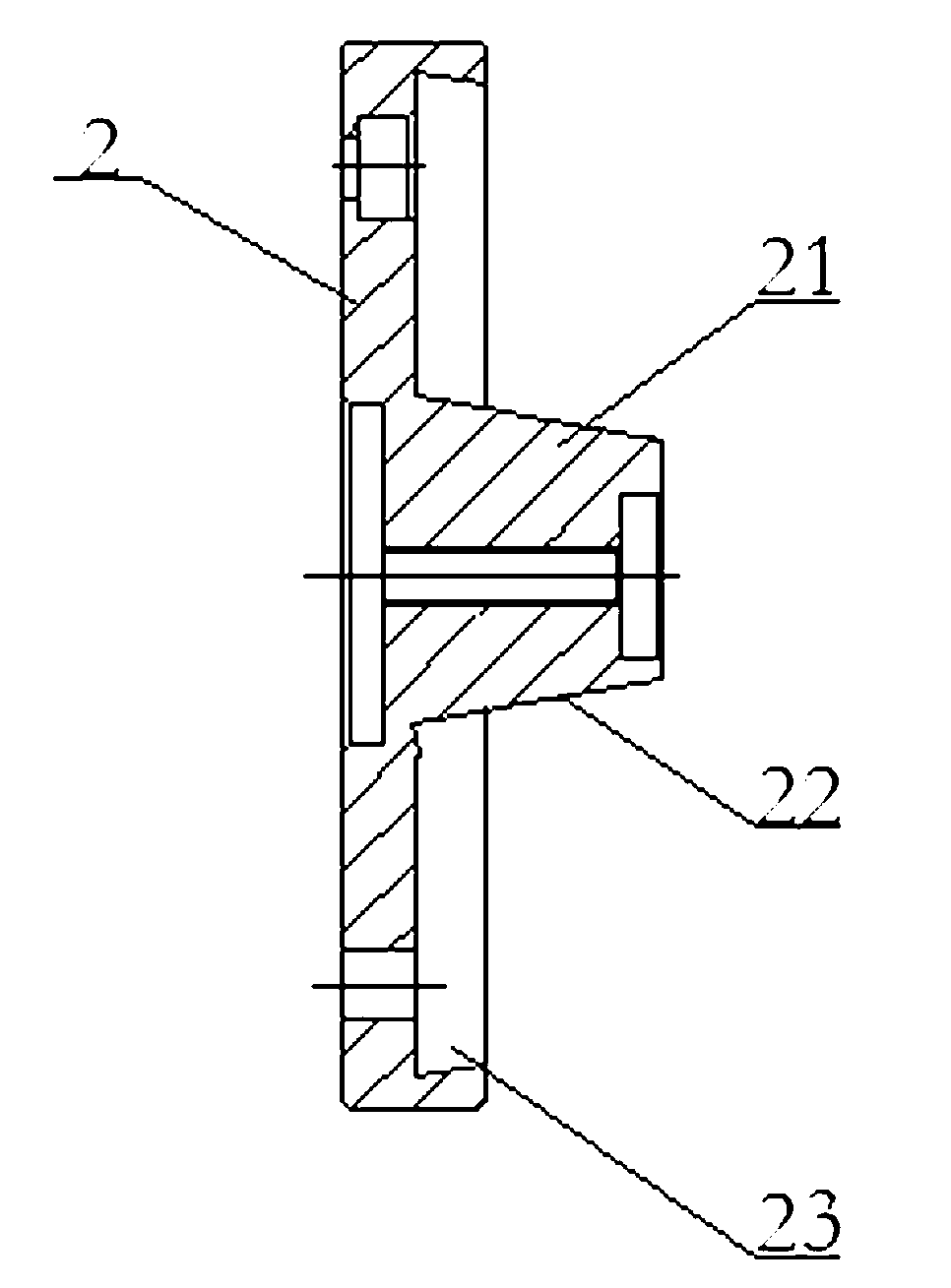

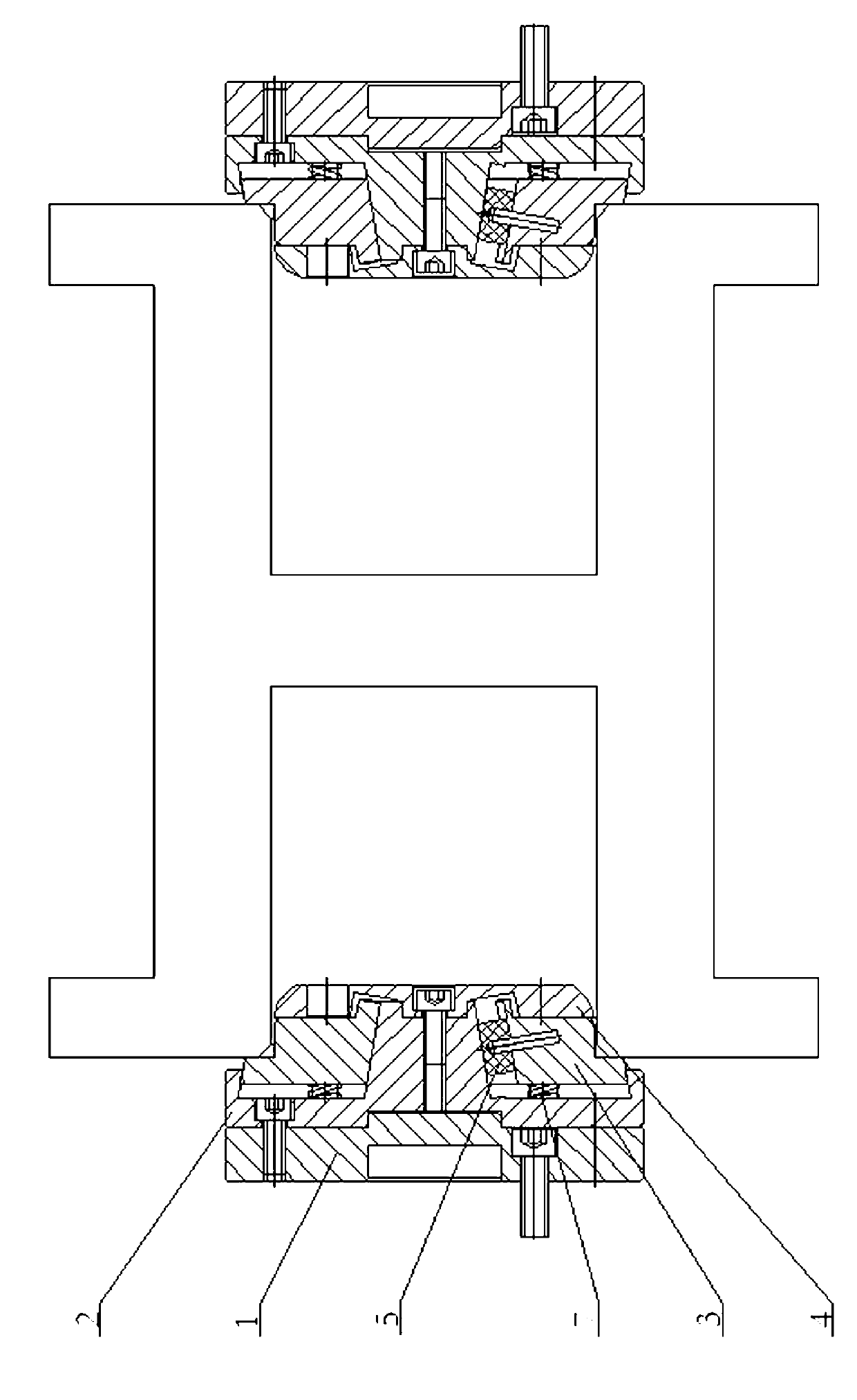

[0015] figure 1 , 2 As shown, an expandable top includes a mold base adapter block 1, an expandable mold base 2 and three expandable tops 3, and the expandable mold base 2 is installed on the mold base adapter block 1, which can be expanded The center of the mold base 2 is provided with a truncated cone 21, and the conical surface of the truncated cone is evenly distributed with three outer slopes 22 along the taper direction. The bottoms of the three expandable tops 3 are supported on the expandable mold by springs 7. On the seat 2, the inner surfaces of the three expandable tops 3 are respectively set on the three outer slopes 22 in a state of sliding up and down along the taper direction of the truncated cone; On the top, the sliding block 5 is connected to the inner surface of the expandable top 3 through the elastic cylindrical pin 6; the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com