Implantable direct acting relief valve

A technology of direct-acting relief valve and valve block, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., and can solve the problems of large installation structure, loose pressure regulating screw, and unreasonable structural settings. Achieve the effects of avoiding volume changes, improving stability, and ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

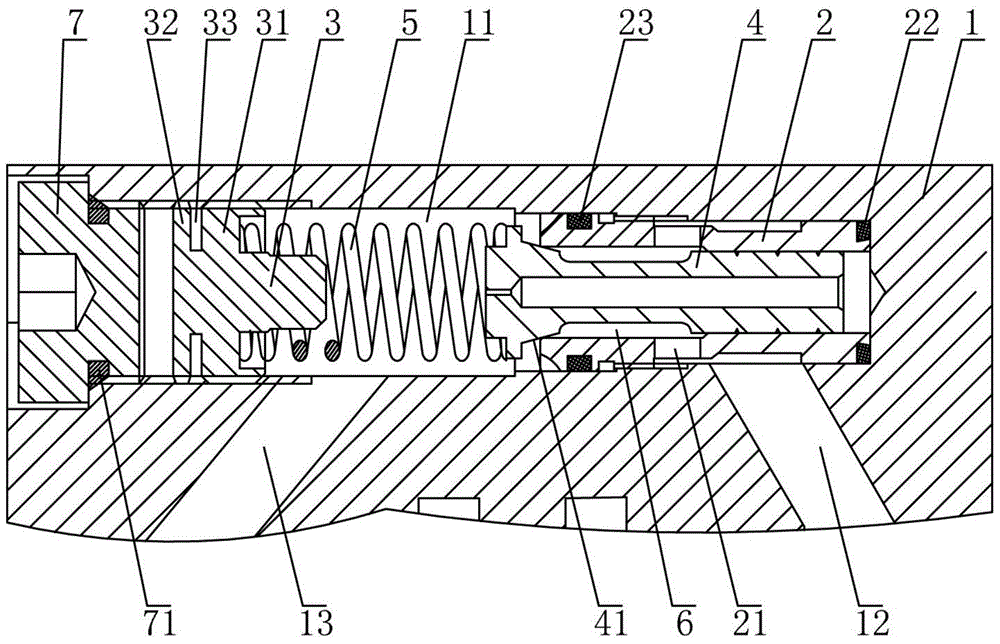

[0015] Such as figure 1 The implanted direct-acting relief valve shown includes a valve block 1, the valve block 1 is provided with a mounting hole 11 along the axial direction, and the valve block 1 is respectively provided with an oil inlet 12 and an oil outlet communicating with the mounting hole 11 Port 13, a safety valve is set in the installation hole 11, the safety valve includes a valve seat 2 and a pressure adjusting screw 3, a valve core 4 is movable in the valve seat 2, and one end of the valve core 4 protrudes from the outside of the valve seat 2, the valve A spring 5 is provided between the protruding end of the core 4 and the pressure adjusting screw 3, a pressure chamber 6 is formed between the valve seat 2 and the valve core 4, and a valve for connecting the pressure chamber 6 and the oil inlet 12 is provided on the valve seat 2. The oil hole 21, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com