Heavy-load vehicle in-compartment moving device

A shifting device and vehicle technology, which is applied in the field of vehicle engineering, can solve the problems of unsatisfactory space vehicle shifting requirements, large device size, small jacking weight, etc., and achieve small space occupation, high work efficiency, and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

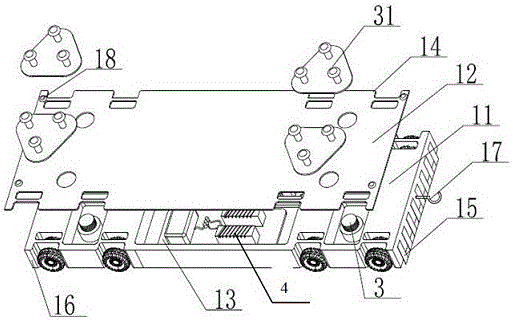

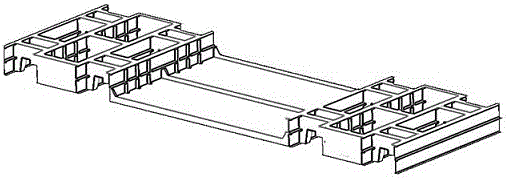

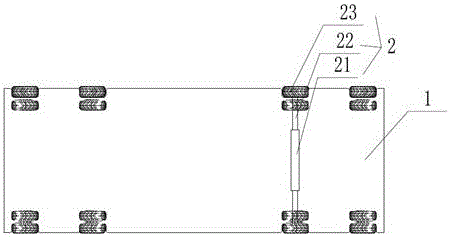

[0031] Such as Figure 1-4 As shown, a displacement device in the cabin of a heavy-duty vehicle includes a platform main structure 1, a power system 2, a jacking system 3 and a control system 4. The platform main structure 1 includes a main beam 11, and the An outer frame 12, an electrical compartment 13 is arranged between the main beam 11 and the outer frame 12; the power system 2 includes a motor drive group 21, a coupling 22 connected to the motor drive group 21, and a coupling 21 Mecanum wheel 23; the jacking system 3 is a hydraulic jack; the hydraulic jack is arranged on the platform main structure 1; the control system 4 is arranged in the electrical compartment 13, including a travel controller, an operation control controllers, motor drive modules, power management devices and remote controls. A battery pack is arranged next to the control system 4, and the control system 4 and the battery pack are located in the electrical compartment. The battery compartment adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com