Structural nondestructive hydraulic dismantling robot

A technology for dismantling robots and hydraulics, applied in metal processing and other directions, can solve problems such as poor cutting ability and inability to cut completely vertically, and achieve the effect of improving quality and ensuring smooth adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

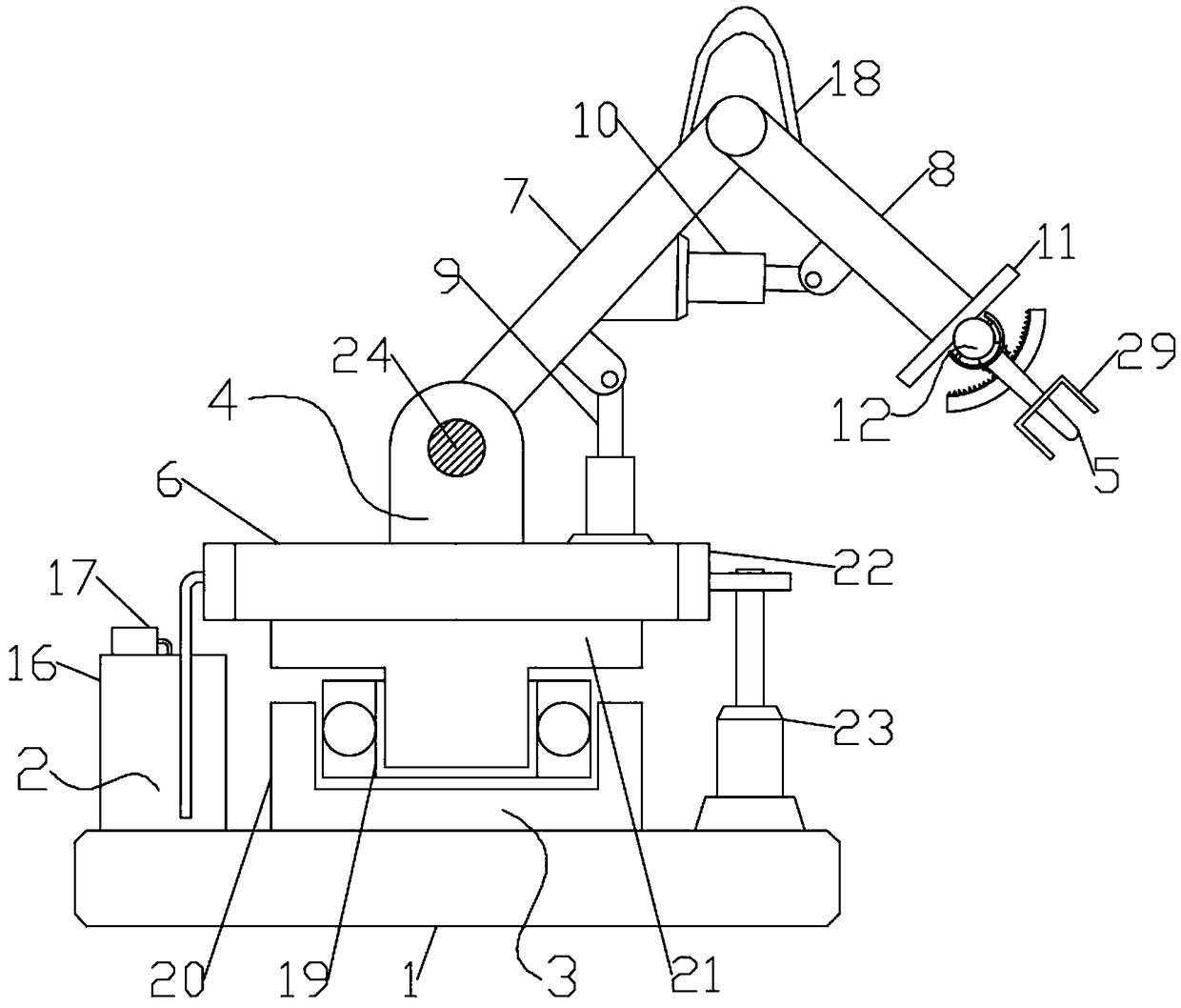

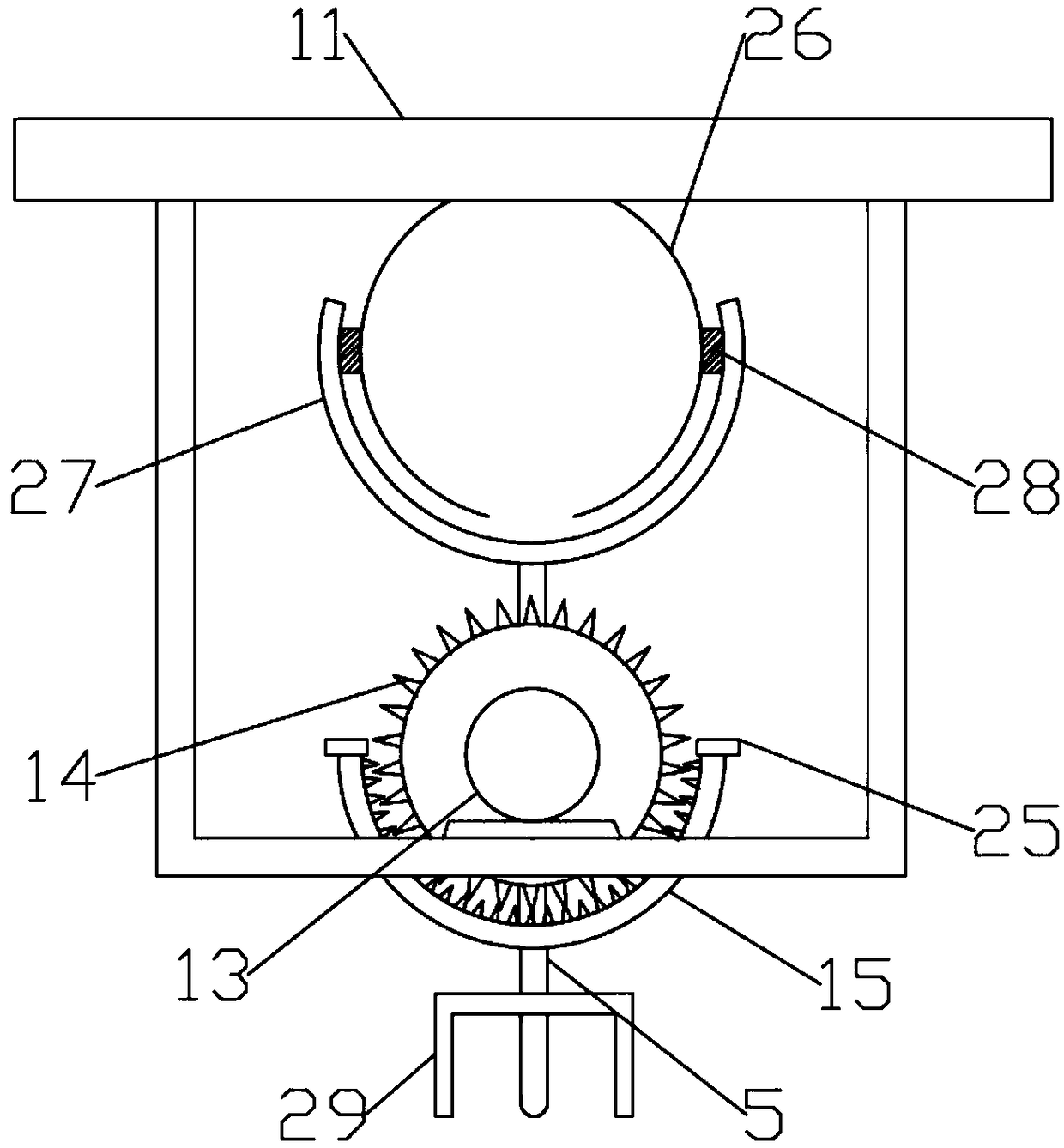

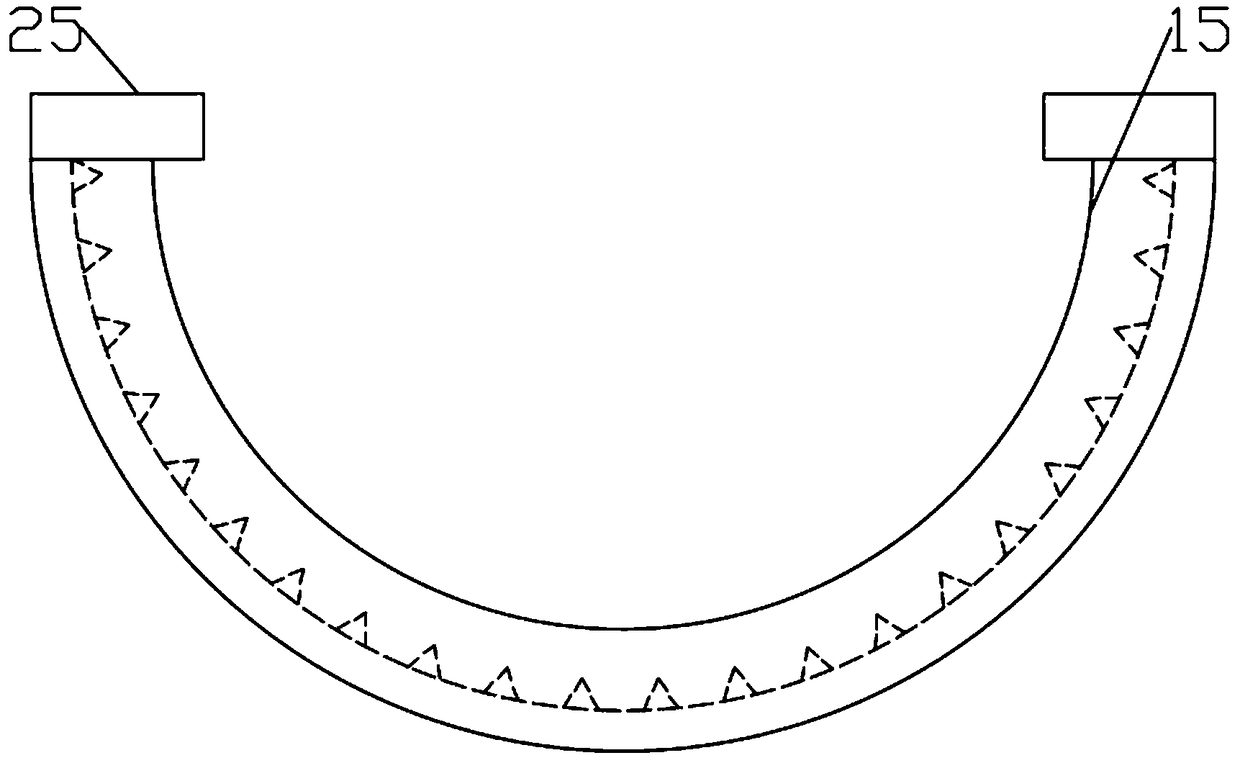

[0026] according to figure 1 , 2 , 3, this embodiment proposes a structurally non-destructive hydraulic demolition robot, including a base 1, a high-pressure water delivery device 2 arranged on the base 1, and a rotating disk 3 movably installed on the base 1. The upper positioning adjustment device 4 and the hydraulic cutting head 5 fixedly installed on the positioning adjustment device 4 and connected to the high-pressure water delivery device 2; the positioning adjustment device 4 includes A fixed base 6, the center position of the upper surface of the fixed base 6 is movably installed with a first mechanical arm 7, and a lifting cylinder 8 is connected between the first mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com