Sealing structure for bottom door of hopper wagon

A technology of sealing structure and funnel car, which is applied in the direction of funnel car, transport passenger car, railway car body parts, etc., can solve the problem of sealing and safe transportation of materials with small bulk density and small particles, and improve welding quality and stability , The effect of constant production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

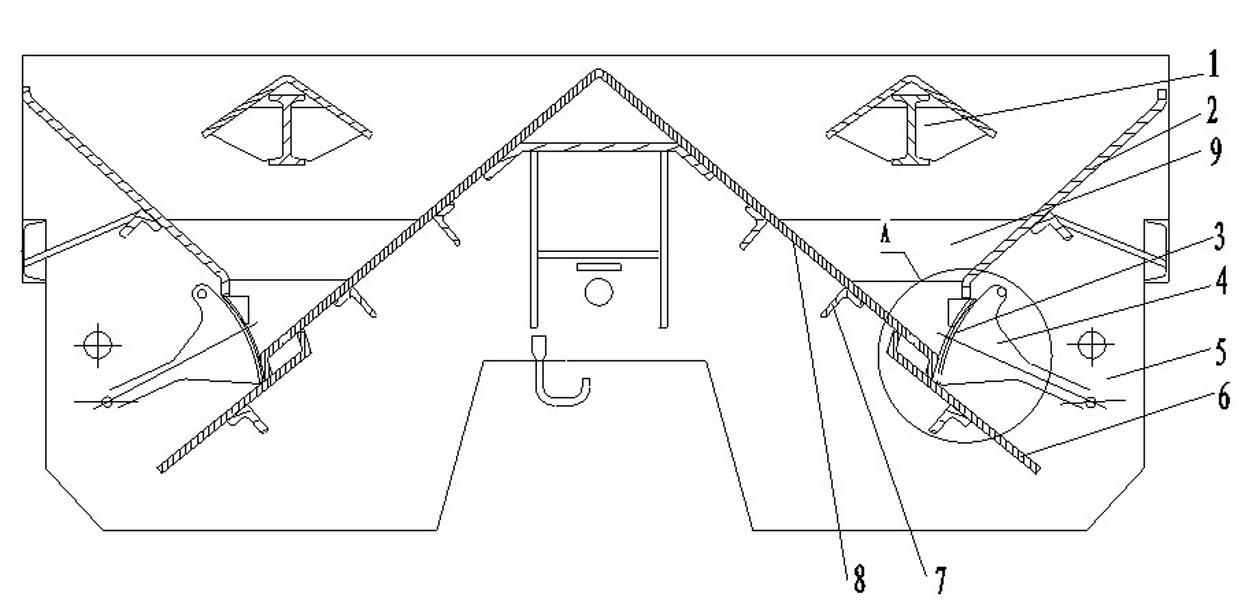

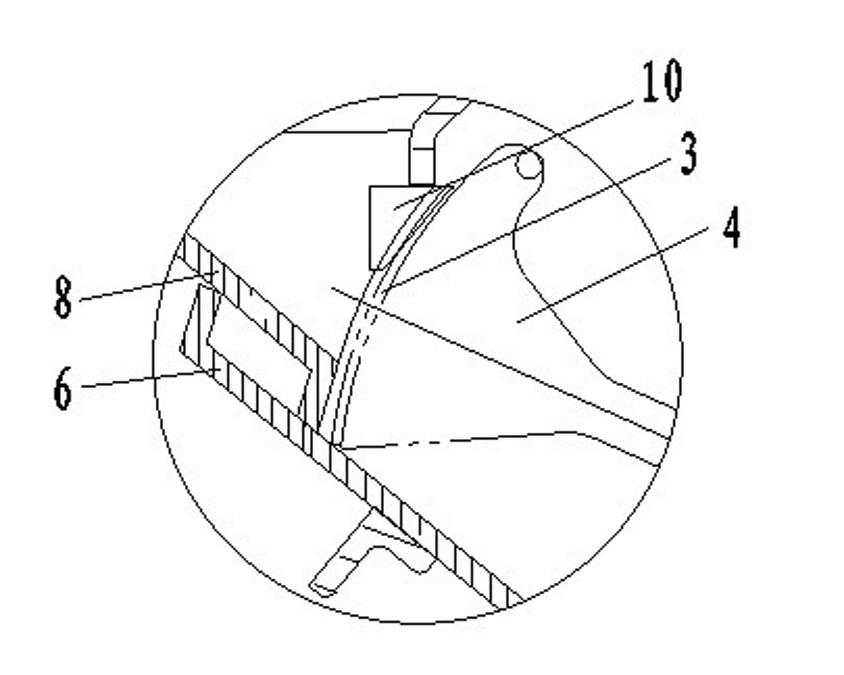

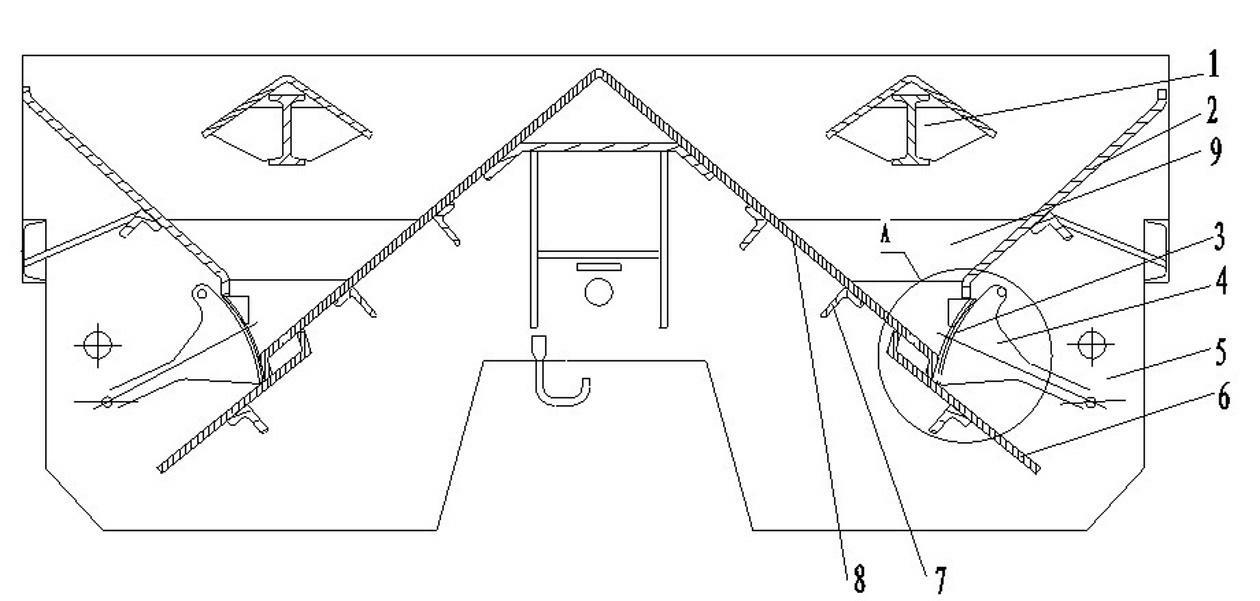

[0014] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0015] The present invention strengthens and enlarges the ballasting beam 1 in the funnel, and reduces the load on the bottom door (see figure 1 : Part No. 3) Pressure. An angle steel 7 is added to the lower part of the middle funnel plate 8 to improve the rigidity of the middle funnel plate. The 6 corners of the ballast plate and the 8 corners of the middle funnel plate are staggered and welded to form a box-shaped structure between the ballast plate 6 and the middle funnel plate 8, which improves the strength and rigidity of the funnel mouth. At the same time, the ballast plate and the middle funnel plate Strength and stiffness have also been improved. Moreover, the design of the funnel mouth can use a special welding machine for the welding process, so that the weld seam can be formed at one time and the welding quality can be improved.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com