The Control of the Adjustable Tensioning Device of Triangular Rib Belt in Automobile Transmission

A technology of tensioning device and triangular rib, applied in the direction of transmission, belt/chain/gear, machine/engine, etc., can solve the problems of shortened service life and increased fuel consumption, and achieve the effect of high belt tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] figure 2 Schematic representation of a car 1 in the form of a passenger car (PKW), which has a figure 1 The internal combustion engine 10 is shown in detail in FIG.

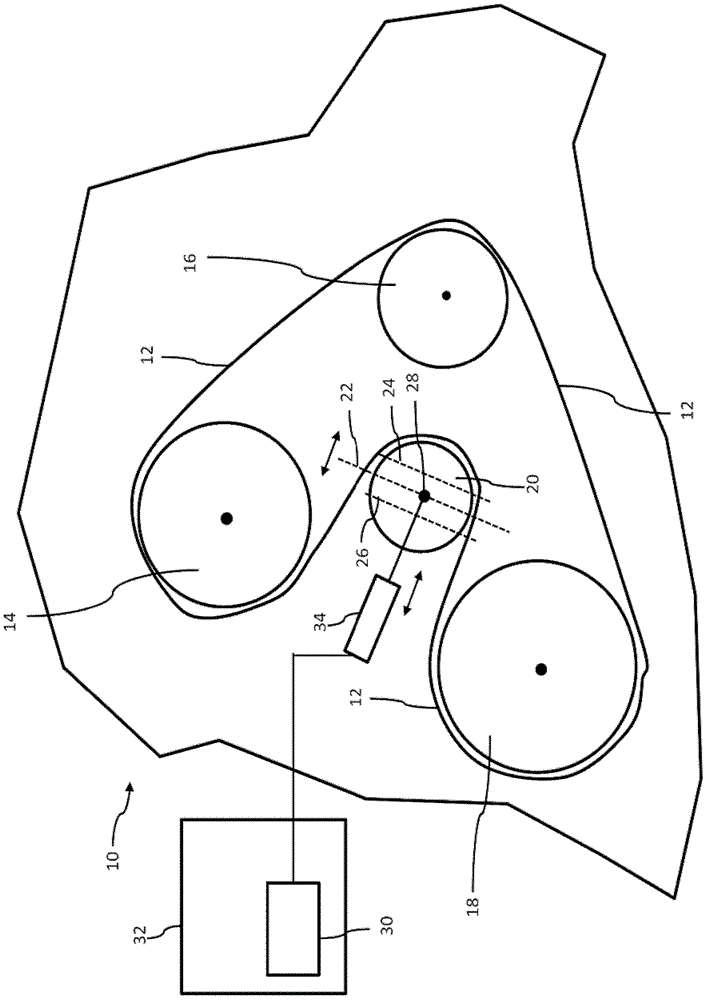

[0040] figure 1 A schematic diagram of a V-belt drive of an internal combustion engine 10 is shown schematically, the crankshaft of which is provided with a belt pulley 18 on the output side. exist figure 1 In the vehicle engine unit 10 shown, there are other auxiliary or additional devices not shown in detail here. The belt pulley 16 is assigned, for example, to the generator, and the belt pulley 14 is assigned to the coolant pump.

[0041] exist figure 1 All the pulleys 14, 16, 18 shown in , are engaged with each other by means of a closed loop V-rib belt 12. While the engine is running and thus the pulley 18 is rotating, auxiliary or additional equipment, such as a generator or a coolant pump, is driven continuously, or, for example, an air conditioning compressor is driven temporarily.

[0042]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap