Lens barrel and image pickup device

A technology of lens barrel and camera device, which is applied in the direction of printing device, projection device, installation, etc., can solve the problem of increasing the thickness of the lens barrel, and achieve the effect of good aberration correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

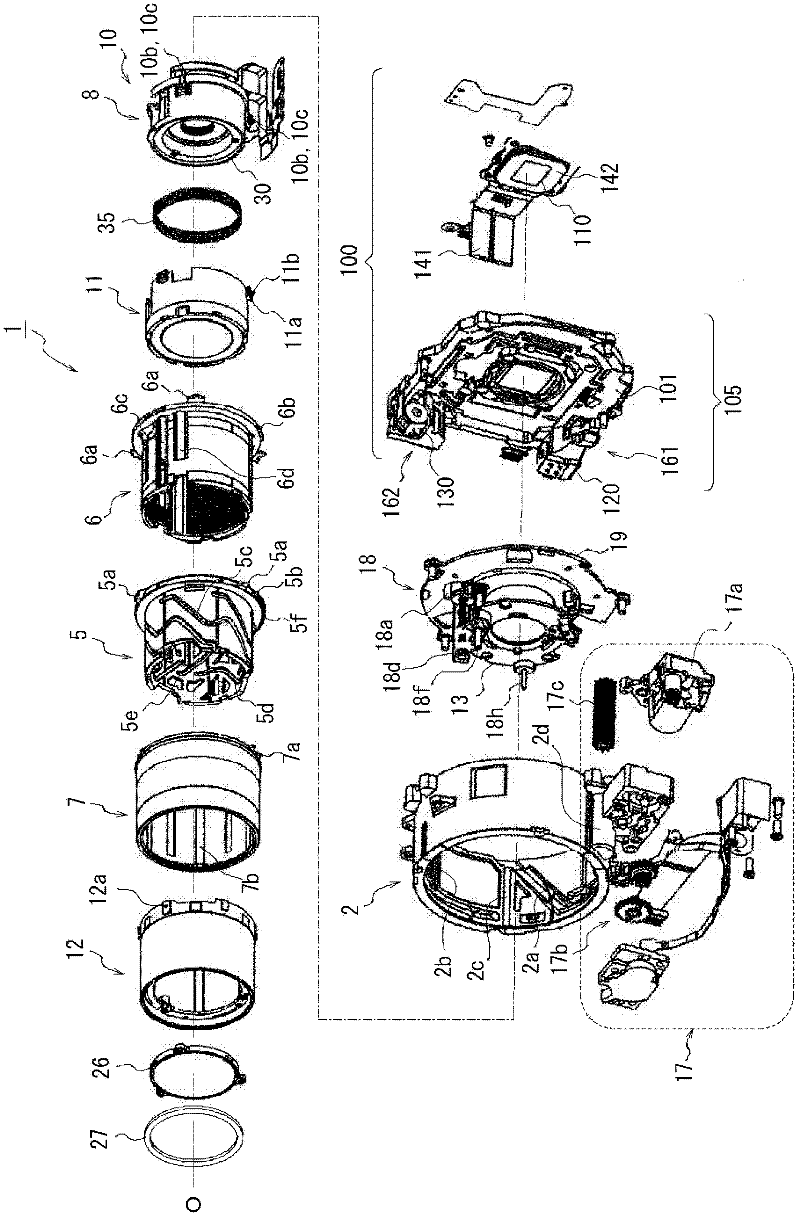

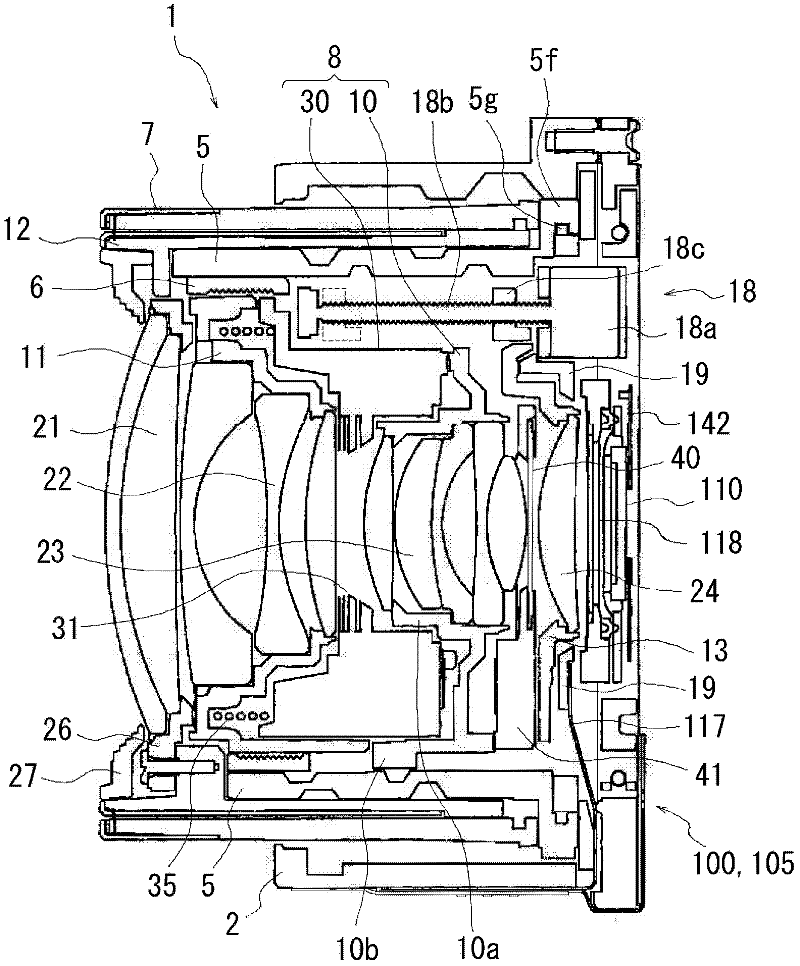

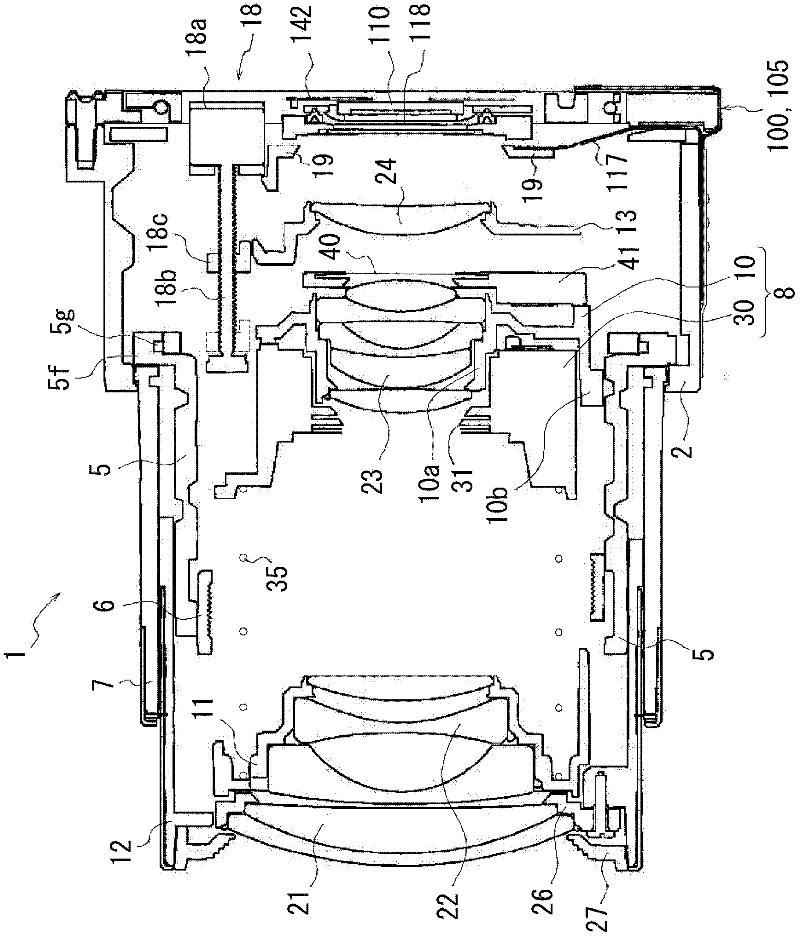

[0102] Hereinafter, an imaging device according to an embodiment of the present invention will be described with reference to the drawings.

[0103] In addition, in the description of the present embodiment, the optical axis (photographic optical axis) of the photographic optical system of the lens barrel is denoted by symbol O. In the direction along the optical axis O (imaging optical axis direction), the subject side (object side) is referred to as the front, and the direction in which each frame member of the lens barrel faces forward is referred to as the extending direction. On the other hand, in the direction along the optical axis O, the imaging side (image side) is referred to as the rear, and the direction in which each frame member faces the rear is referred to as a pull-in direction. In addition, the rotation direction of each component part of a lens barrel is shown by the rotation direction seen from the front side.

[0104] The imaging device of this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com