Low-density multilayer circuit board capable of integrating high-density multilayer board as well as manufacturing method thereof

A technology of a multilayer circuit board and a manufacturing method, which is applied in the directions of multilayer circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as raising manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

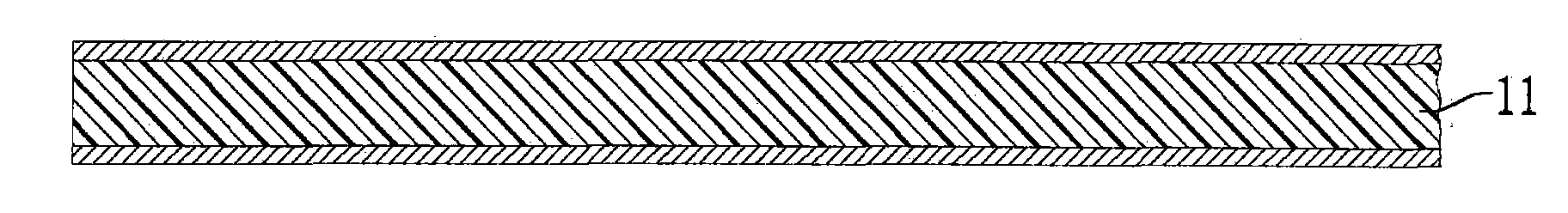

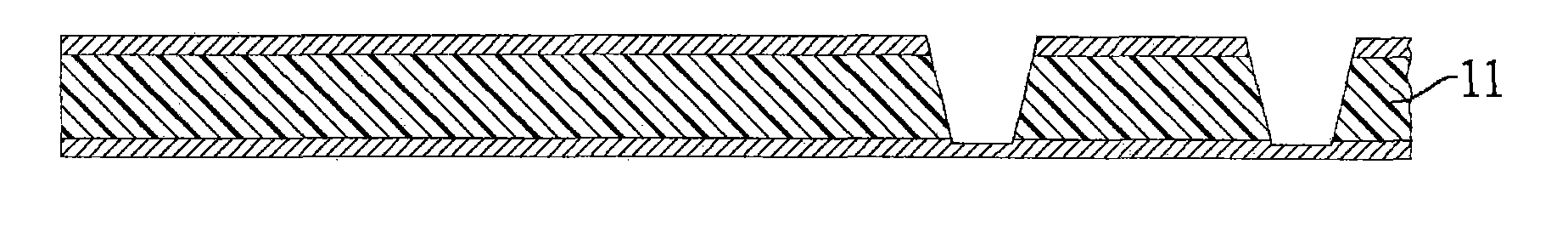

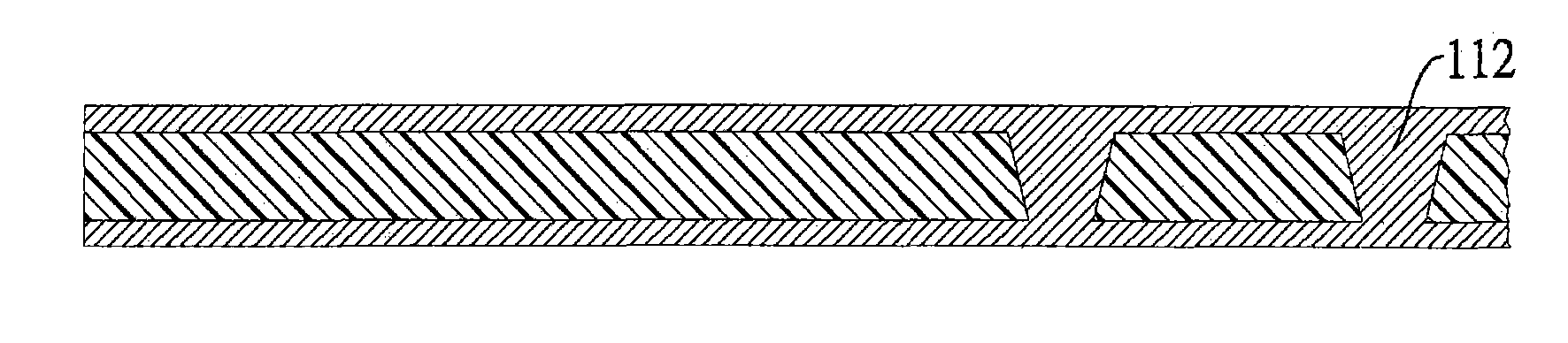

[0022] The present invention provides a flow chart of a low-density multilayer circuit board manufacturing method that integrates high-density multilayer boards. First, please refer to Figures 4A to 4D and Figure 5 , the preparation method of the present invention comprises the following steps:

[0023] A low-density motherboard 20 is provided, and the low-density motherboard 20 forms an accommodating space 201; in this embodiment, the low-density motherboard 20 is a multi-layer board with six circuit layers, or a single laminate;

[0024] A prefabricated high-density multilayer sub-board 10 is accommodated in the accommodating space 201 of the low-density motherboard 20; wherein the two opposite surfaces of the high-density multilayer sub-board 10 are respectively formed with protective layers 16, in this step, The high-density multi-layer sub-board 10 must be positioned and fixed in the accommodating space 201 to perform the next step. Therefore, tight tolerance fitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com