Chip-on-film packaging structure

A thin-film-on-chip packaging, thin-film technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as large film area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

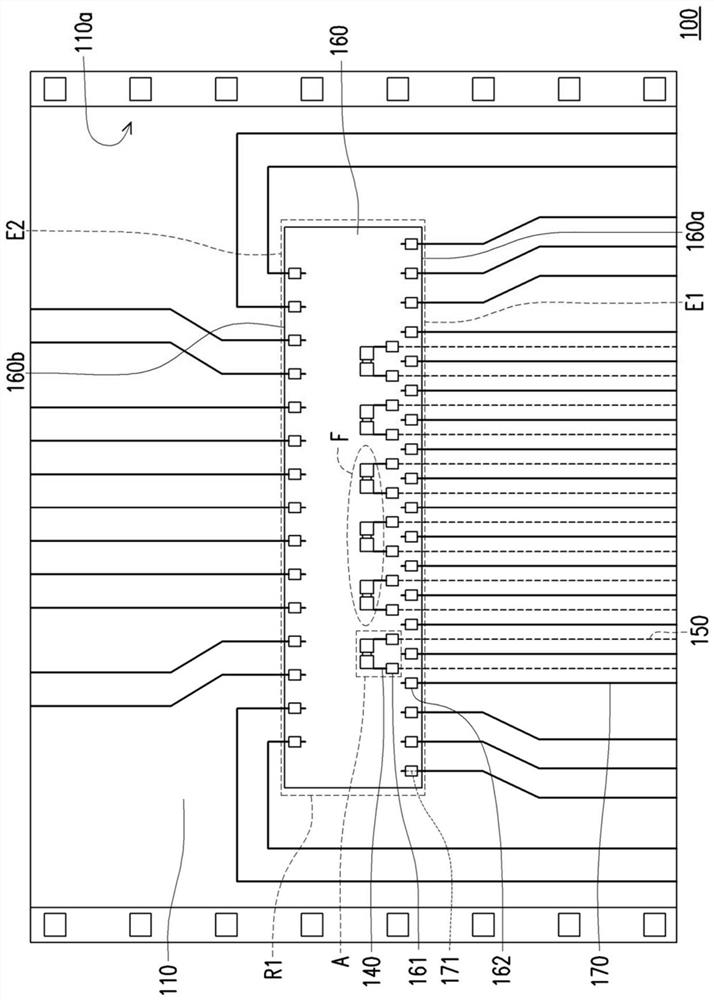

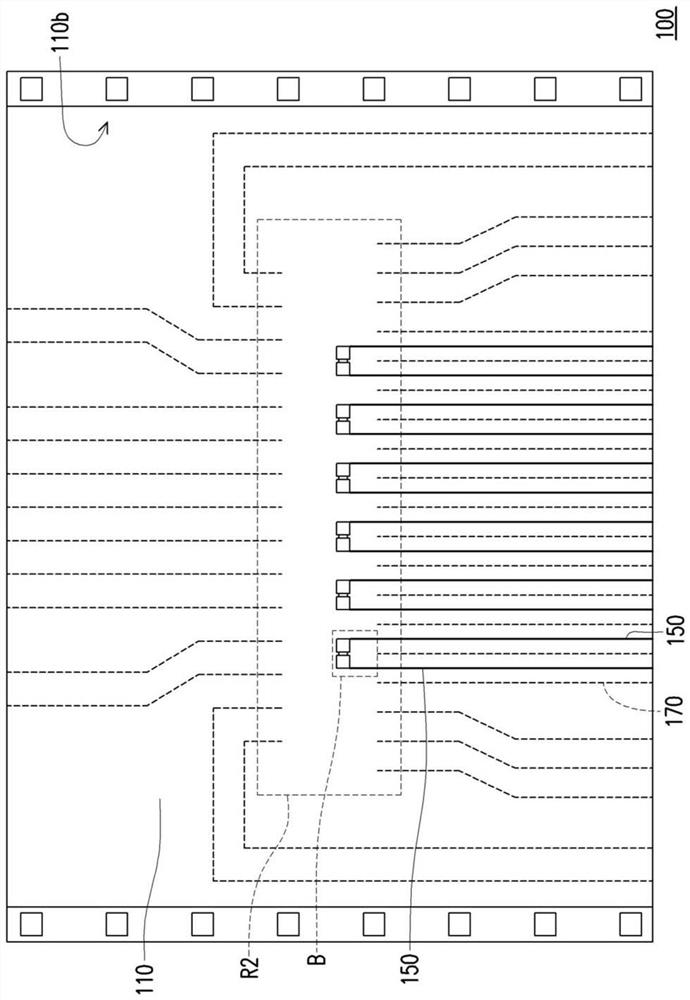

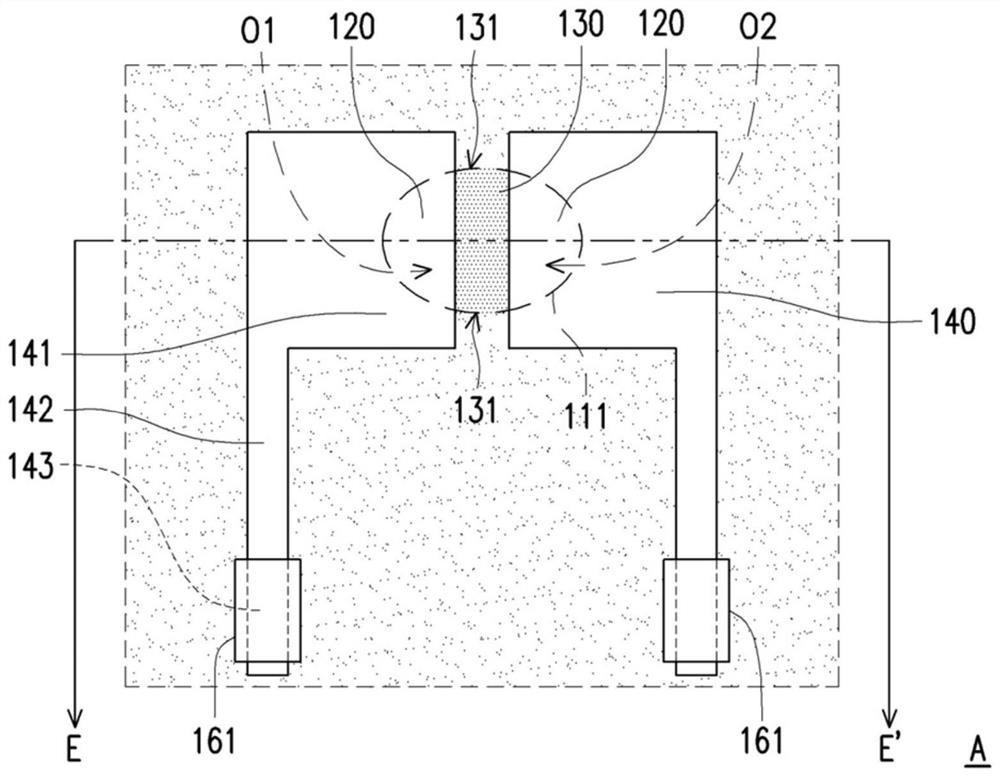

[0051] Figure 1A is a schematic top view of a chip-on-film packaging structure according to an embodiment of the present invention. Figure 1B yes Figure 1A Schematic bottom view of the thin film chip-on-chip packaging structure. Figure 1C yes Figure 1A An enlarged schematic view of region A of . Figure 1D yes Figure 1B An enlarged schematic view of region B of . Figure 1E yes Figure 1C Schematic cross-sectional view along section line E-E'. Figure 1F yes Figure 1A An enlarged schematic view of region F of . In order to clearly show the connection relationship between the chip 160 and the first upper pin 140, Figure 1A The chip 160 is rendered in perspective.

[0052] Please refer to Figure 1A to Figure 1F , in this embodiment, the film-on-chip packaging structure 100 includes a flexible film 110 , at least two conductive elements 120 , an insulator 130 , at least two first upper leads 140 , at least two lower leads 150 and a chip 160 . The flexible film 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com