Element installing device

A technology for installing devices and components, applied in the direction of electrical components, electrical components, etc., to achieve the effect of reducing the number of negative pressure sources and preventing components from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

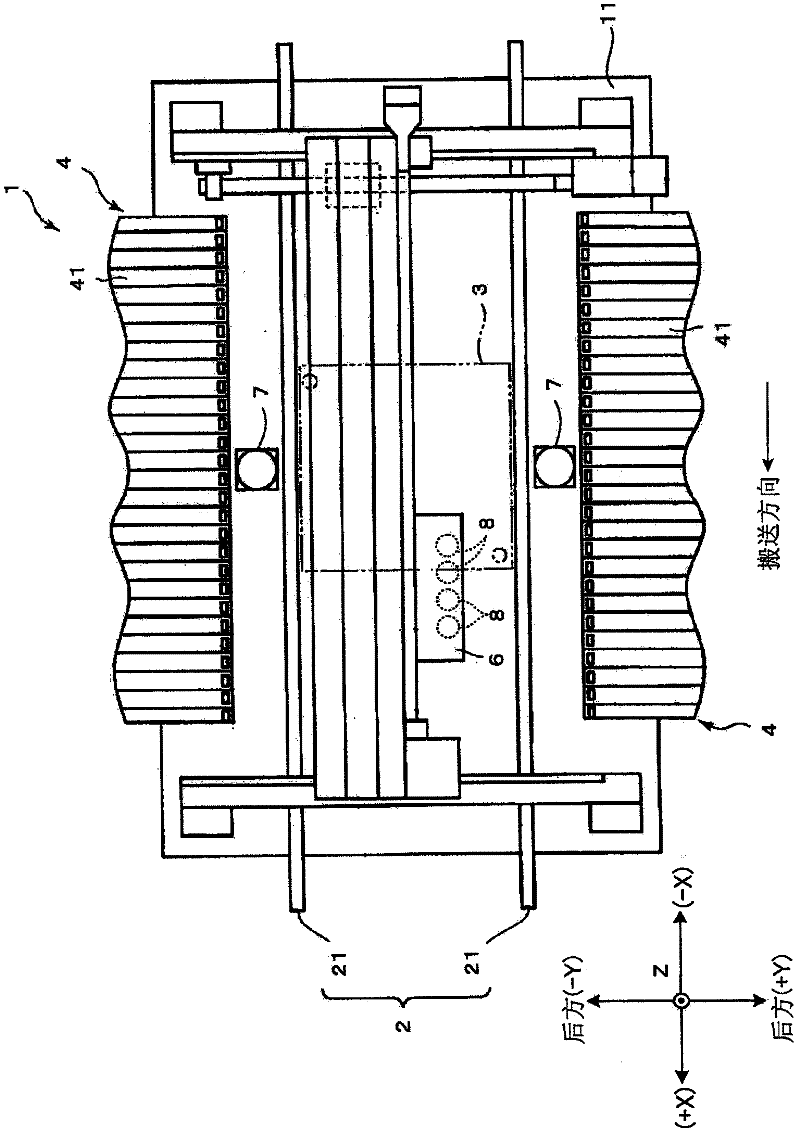

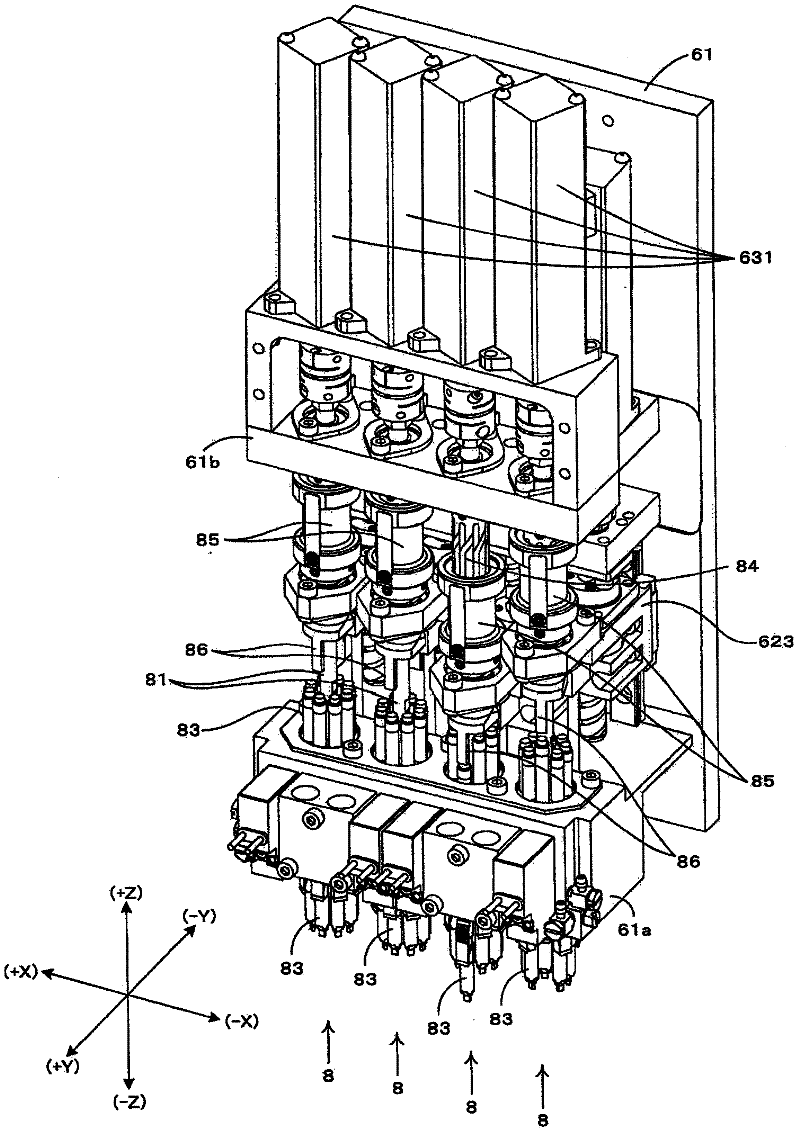

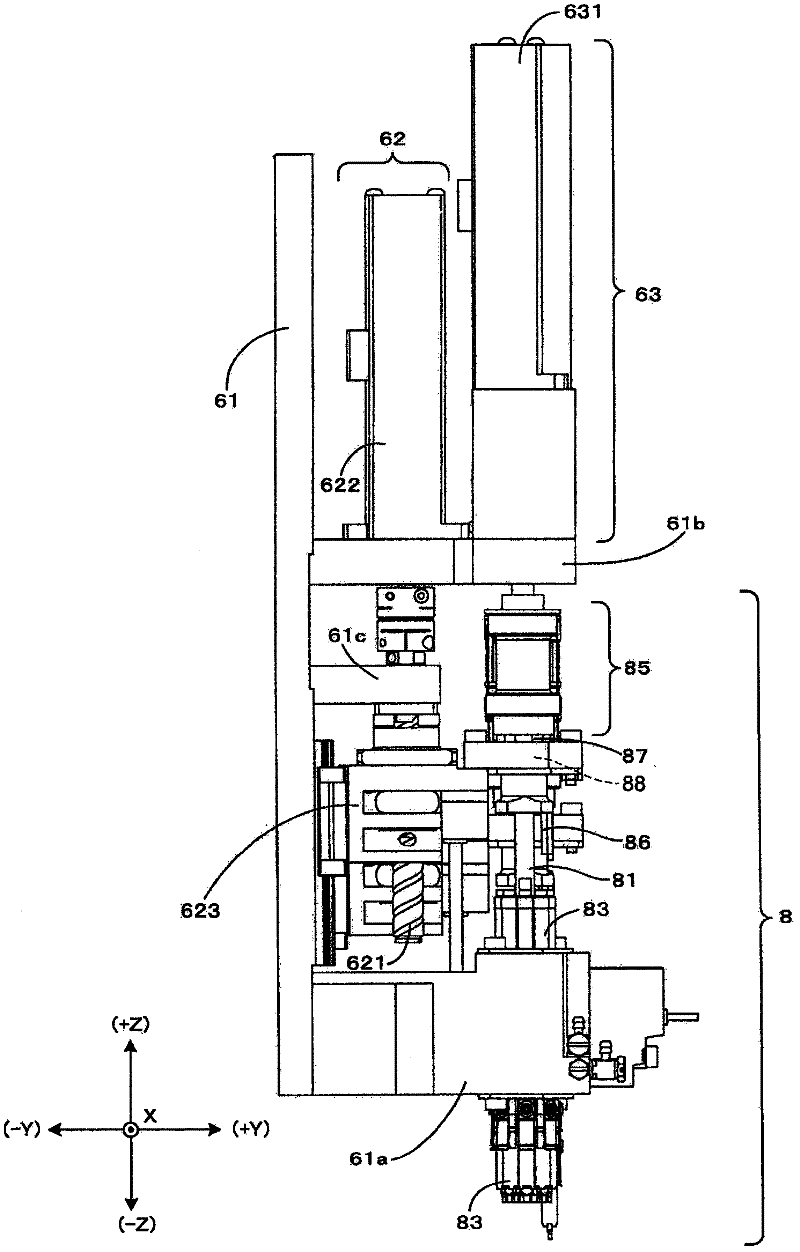

[0059] figure 1 It is a plan view showing the schematic structure of the first embodiment of the component mounting apparatus according to the present invention. In addition, in figure 1 In the drawings described later, XYZ rectangular coordinate axes are used to clarify the directional relationship among the respective drawings. In the XYZ rectangular coordinates, the conveyance direction of the substrate is defined as the X direction, the downstream side in the conveyance direction is indicated by (+), and the upstream side is indicated by (-). In addition, the direction perpendicular to the X direction in plan view is defined as the Y direction, the front is indicated by (+), and the rear is indicated by (-). Furthermore, the up-and-down direction is defined as the Z direction, the upper side is indicated by (+), and the lower side is indicated by (-).

[0060] In this component mounting apparatus 1 , a substrate transport mechanism 2 is provided on a base 11 to transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com