Hollow glass with built-in sun-shading curtain

A sunshade and glass technology, applied in parallel glass structures, shading screens, etc., can solve the problems of large operation force, difficult control accuracy, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

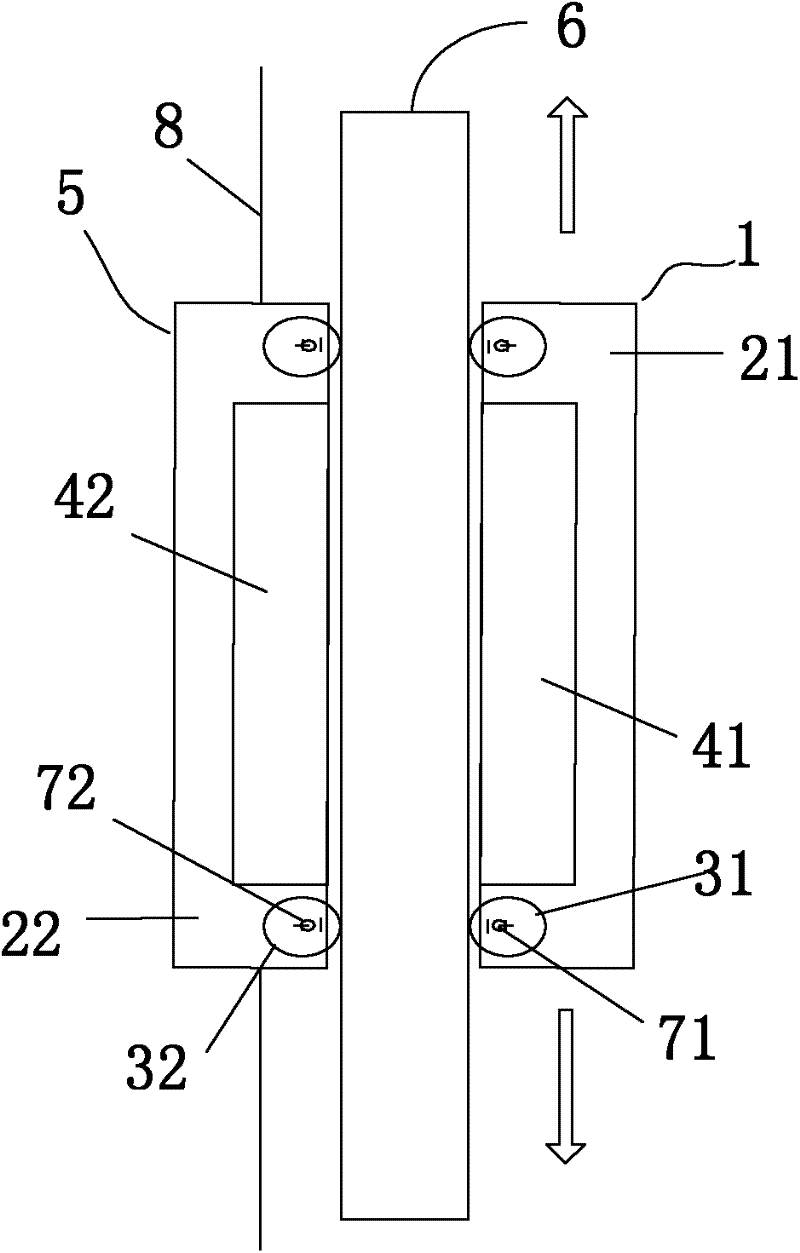

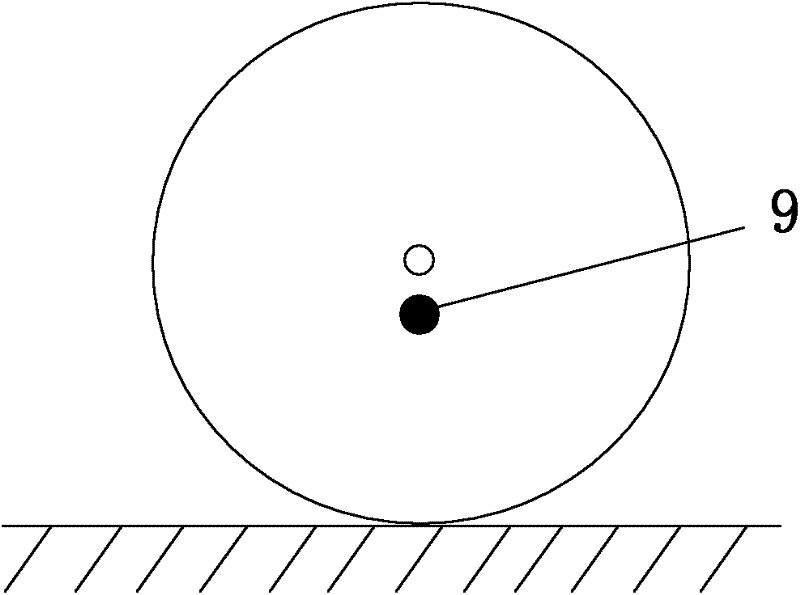

[0026] Embodiment one: if figure 2 As shown, the section of the vertical axis 9 of the roller is circular, and the axis 9 deviates from the center of the circle. Within this range, a better feel can be obtained while ensuring the limit effect. When the roller rotates to the closest position between the axis 9 and the contact surface, the distance between the operating device 1 and the traction device 5 is the shortest and the magnetic force is strongest, and this position is the resistance position. In this embodiment, it is only necessary to deviate the axis 9 from the center of the circle, and the processing is the simplest and the cost is relatively low.

Embodiment 2

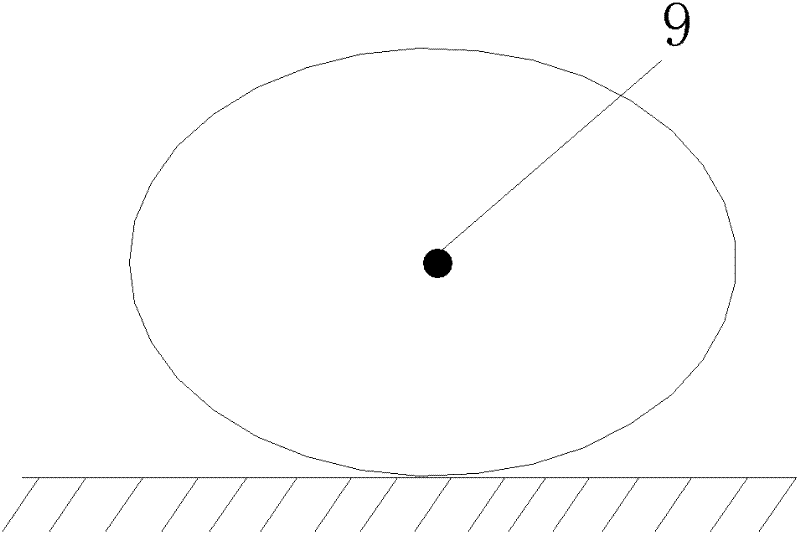

[0027] Embodiment two: if image 3 As shown, the section of the roller along the vertical axis 9 is elliptical. According to the symmetrical characteristics of the ellipse, there are two closest positions between the axis 9 and the contact surface. When the roller rotates to this position, the distance between the operating device 1 and the traction device 5 is the shortest, and the magnetic force is the strongest. The position is the resistance position . Because the roller has two resistance positions in one rolling cycle, the control precision is higher.

Embodiment 3

[0028] Embodiment three: as Figure 4 As shown, the roller is a polyhedral cylinder with a polygonal cross-section perpendicular to the axis 9, and the vertical distance between the axis 9 and the planes of the polyhedron cylinder is the smallest. The distance between the devices 5 is the shortest and the magnetic force is the strongest, and the position is the resistance position. The multi-faceted cylinder can have multiple resistance positions, and the control accuracy is further improved; in addition, the contact surface of the roller at the resistance position is a plane, and the friction force is large, which can reduce the possibility of slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com