Plunger type high-pressure water pump system and high and low-pressure mode switching method thereof

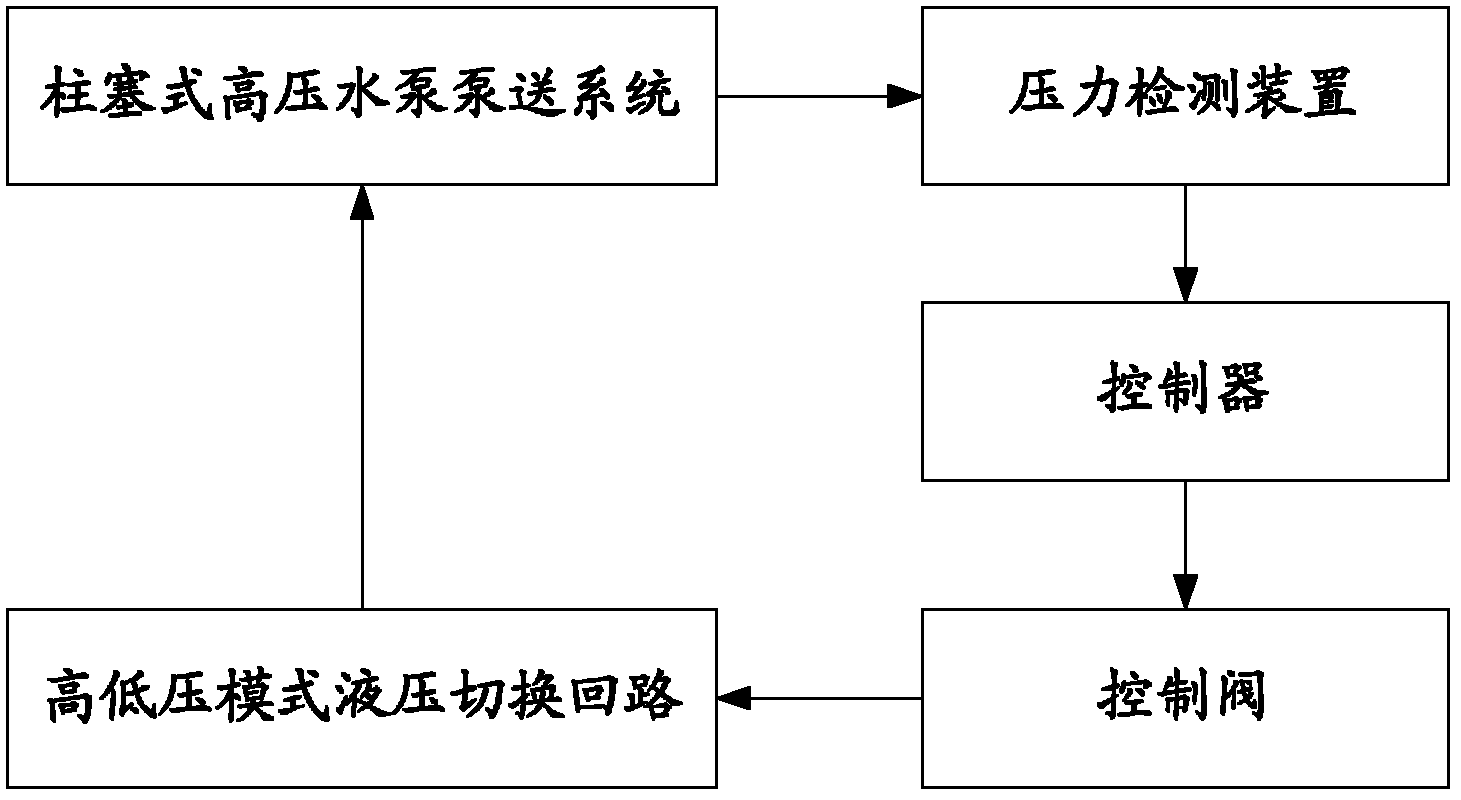

A high-pressure water pump, mode switching technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problems of complex construction site conditions, inability to meet speed and accuracy, and achieve optimal coordination and fast response. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

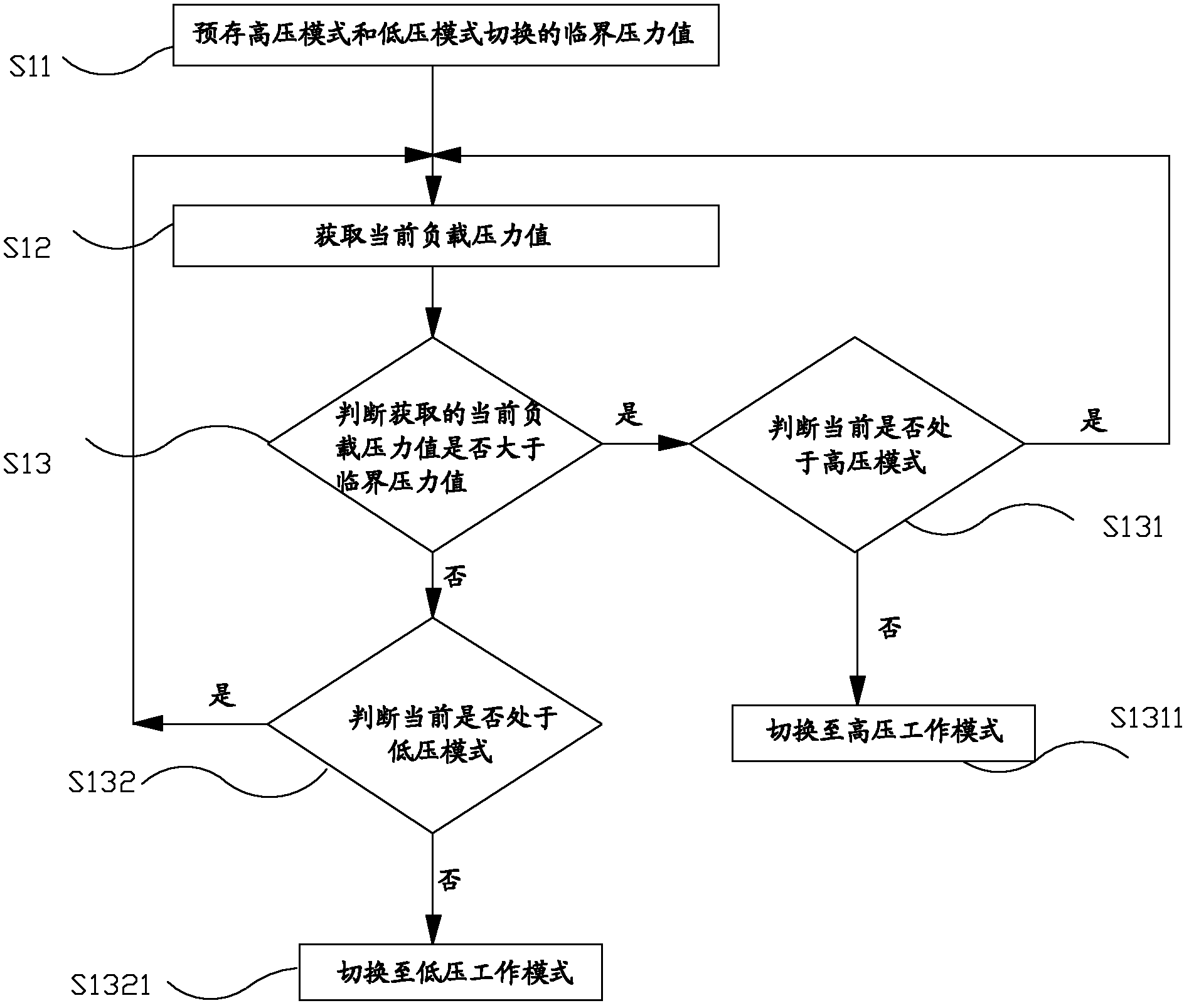

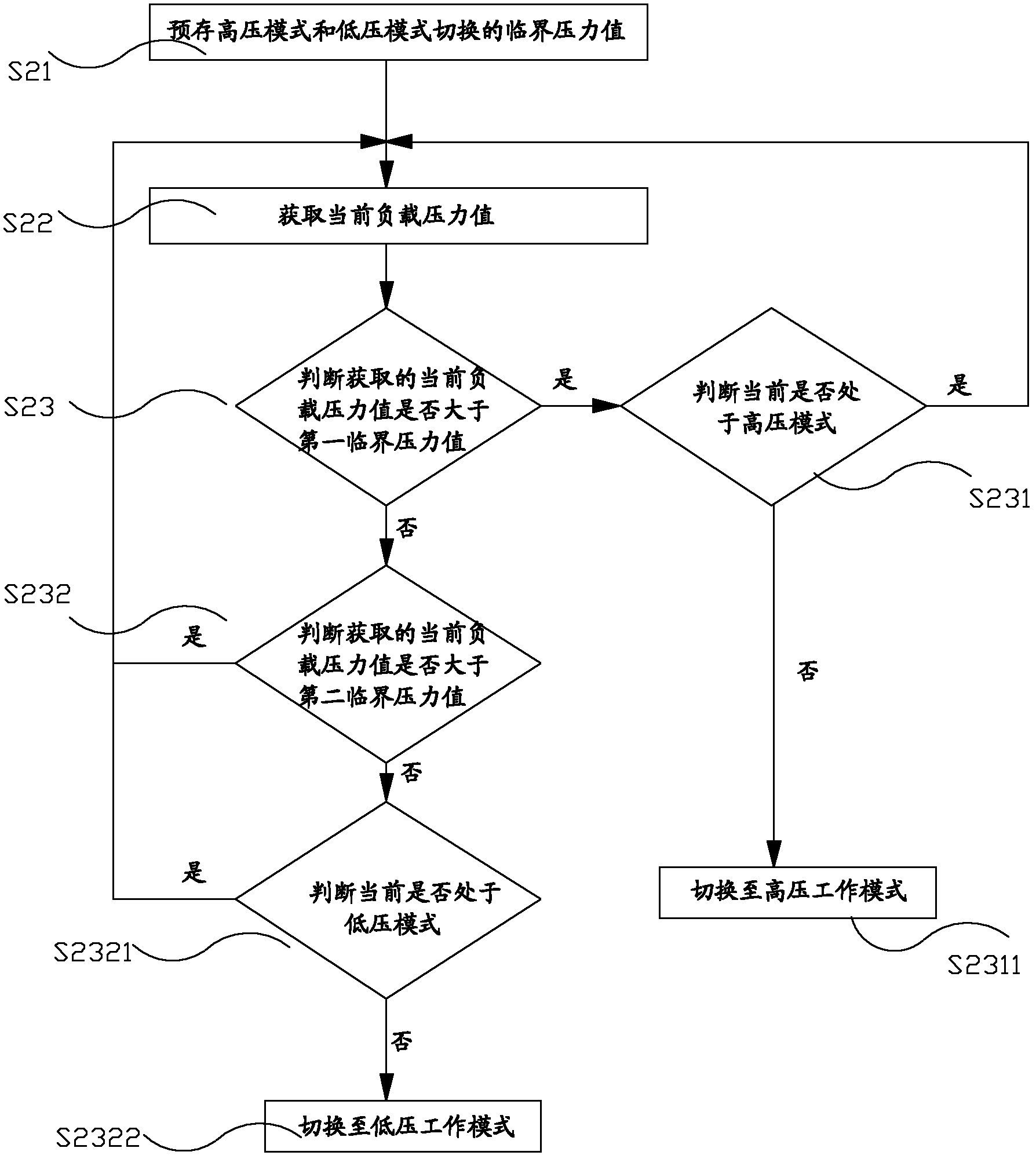

[0068] This particular embodiment comprises the following steps:

[0069] Step S21) pre-store the first critical pressure value P1 for switching from the low pressure mode to the high pressure mode, and the second critical pressure value P2 for switching from the high pressure mode to the low pressure mode;

[0070] Wherein, the first critical pressure value P1 is greater than the second critical pressure value P2;

[0071] With respect to the first specific embodiment, the pre-stored critical pressure values in this embodiment include the first critical pressure value P1 and the second critical pressure value P2, both of which are pre-stored in the storage unit of the controller.

[0072] Step S22) obtain the current load pressure value P';

[0073] This step is the same as the first specific implementation manner, and can be understood with reference to the above content.

[0074] Step S23) judging whether the acquired current load pressure value P' is greater than the f...

Embodiment approach

[0084] In fact, for the first specific implementation of the switching method, the order of the two steps of judging the relationship between the load pressure value and the critical pressure value and judging the current working mode can be reversed. Please refer to Figure 5 and combine Figure 4 , Figure 5 It is a flow chart of the third embodiment of the high-low pressure mode switching method of the plunger type high-pressure water pump system provided by the present invention.

[0085] The high-low pressure mode switching method of the plunger type high-pressure water pump system includes the following steps:

[0086] S31) Pre-store the critical pressure value for switching between the high-pressure mode and the low-pressure mode;

[0087] S32) obtaining the current load pressure value;

[0088] S33) judging whether it is currently in the high-voltage mode; if yes, then enter step S31); otherwise, enter step S32);

[0089] S31) judging whether the current load pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com