Hydrodynamic force converter and refrigerating plant with same

A fluid power and refrigeration device technology, applied in the direction of pump devices, refrigerators, refrigeration components, etc., can solve the problems of unfavorable energy saving, large starting current, and affecting the life of the compressor, so as to achieve environmental protection and energy saving, improve service life, and avoid frequent The effect of starting and stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

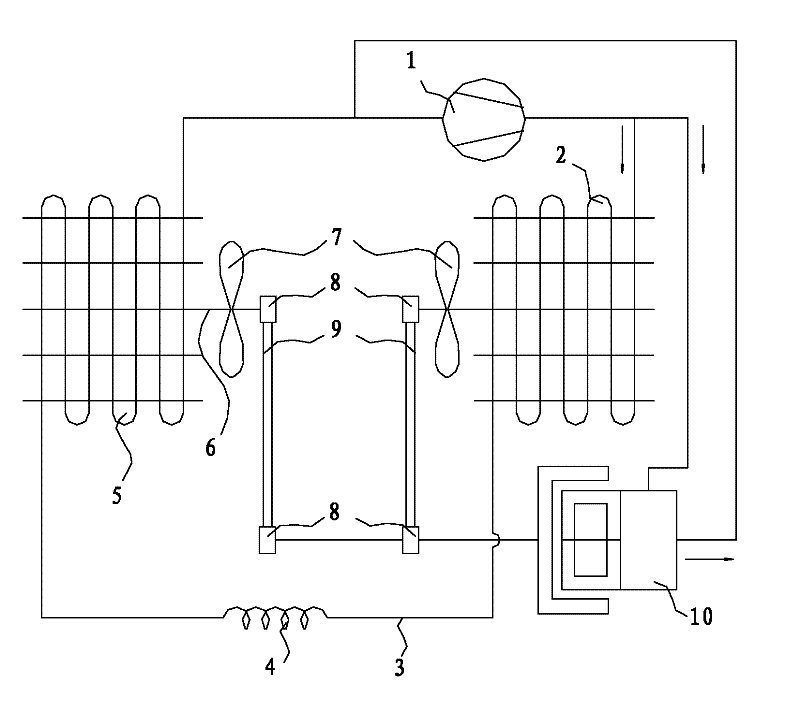

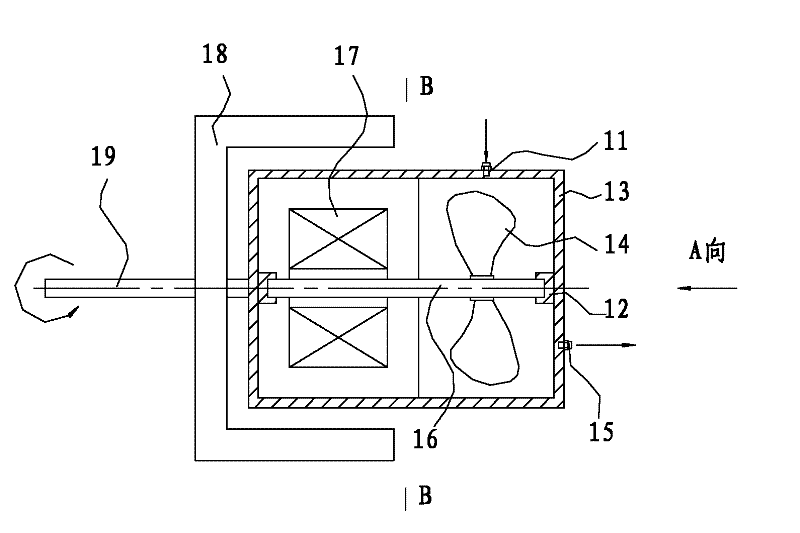

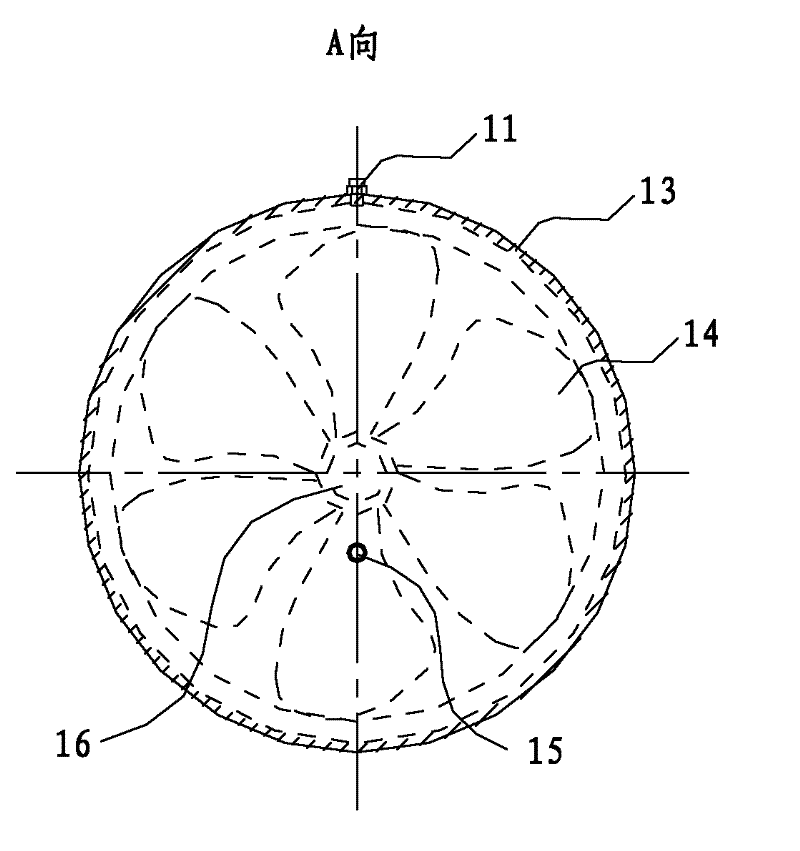

[0028] Such as Figure 1 to Figure 4 As shown, the refrigeration device includes a compressor 1, a first heat exchanger 2, a second heat exchanger 5, a throttling device 4, a system connecting pipe 3, a compressor 1, a first heat exchanger 2, a throttling device 4 and The second heat exchanger 5 is sequentially connected by the system connecting pipe 3 to form a refrigeration cycle. The refrigeration device also includes a fluid power converter 10, and the fluid power converter 10 is arranged on the cold cycle circuit. , the fluid dynamic converter 10 includes a nozzle 11, an impeller, an inner rotor magnet 17, an outer rotor magnet 18 and a driven shaft 19, the nozzle 11 is opposite to the impeller, and the impeller is fixedly connected to the inner rotor magnet 17 and placed in the cavity 13, The outer rotor magnet 18 is disposed outside the cavity 13 and corresponds to the inner rotor magnet 17 , and the driven shaft 19 is fixedly connected to the outer rotor magnet 18 . ...

Embodiment 2

[0036] Such as Figure 5 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that the nozzle 11 of the fluid dynamic converter 10 communicates with the first heat exchanger 2, and the discharge port 15 and the suction port of the compressor 1 pass through the system connecting pipe 3 connected. The circulation loop formed by the fluid power converter 10, the first heat exchanger 2, and the compressor 1 is connected to the compressor 1, the first heat exchanger 2, the throttling device 4, and the second heat exchanger 5 in sequence through the system connecting pipe 3 The formed refrigeration cycle loops are connected in parallel.

Embodiment 3

[0038] Such as Figure 6 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that the nozzle 11 of the fluid dynamic converter 10 communicates with the first heat exchanger 2, and the discharge port 15 of the fluid dynamic converter 10 communicates with the second heat exchanger 5 Connected through the system connection pipe 3. The circulating circuit formed by the fluid power converter 10, the first heat exchanger 2, and the second heat exchanger 5 is connected with the compressor 1, the first heat exchanger 2, the throttling device 4, and the second heat exchanger 5 through a system connecting pipe. 3 are connected in turn to form a refrigeration cycle in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com