Measuring tool

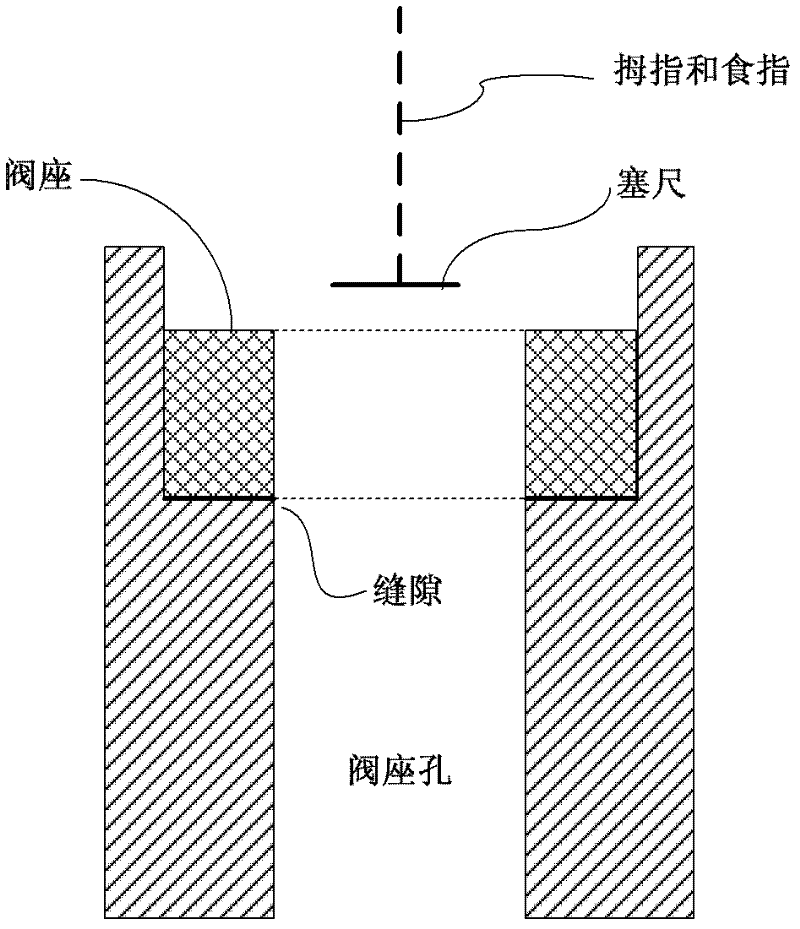

A measurement tool and tool technology, applied in the field of measurement, can solve the problems of fragile feeler gauge, low accuracy and efficiency, and achieve the effect of overcoming inconvenient operation, not easy to bump, and improving measurement accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems to be solved, features and advantages of the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

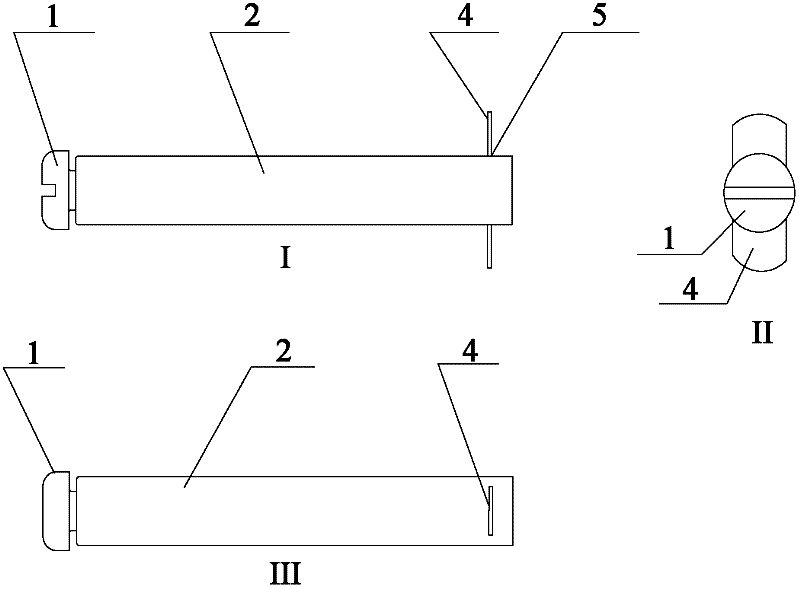

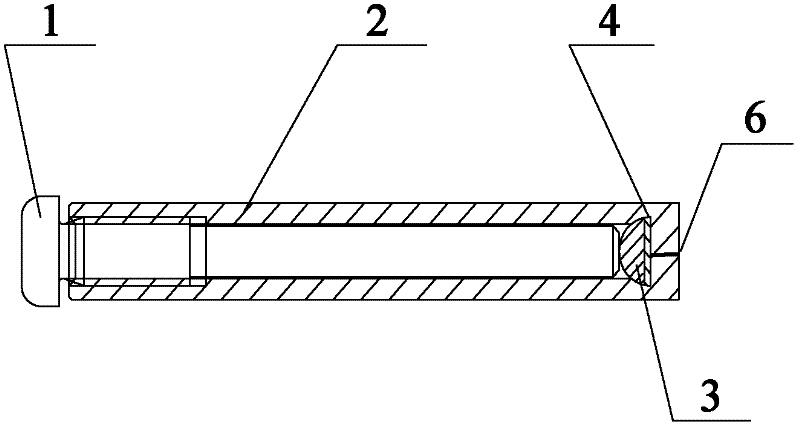

[0030] The invention provides a measuring tool, figure 2 is a three-view view of an embodiment of the present invention ( figure 2 Middle I is the main view, II is the left view, and III is the top view). The measuring tool includes: a tightening screw 1, a body 2, a pressure block 3, a feeler gauge 4, and a rectangular hole 5 is opened on the body 2. Specifically:

[0031] (1) Feeler gauge:

[0032] Feeler gauge 4 belongs to the prior art, is a kind of sheet-shaped gauge, measures the size of gap with its thickness. Its length, width, and thickness can have various values. The feeler gauge 4 can be a standard feeler gauge, or a non-standard feeler gauge processed by the user himself, as long as its thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com