Device for preventing hydro-pneumatic spring from swinging

A technology of oil-pneumatic spring and swing device, which is applied in the direction of elastic suspension, transportation and packaging, suspension, etc., can solve the problems of joint bearing damage, noise, etc., and achieve the effect of eliminating noise and reducing swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

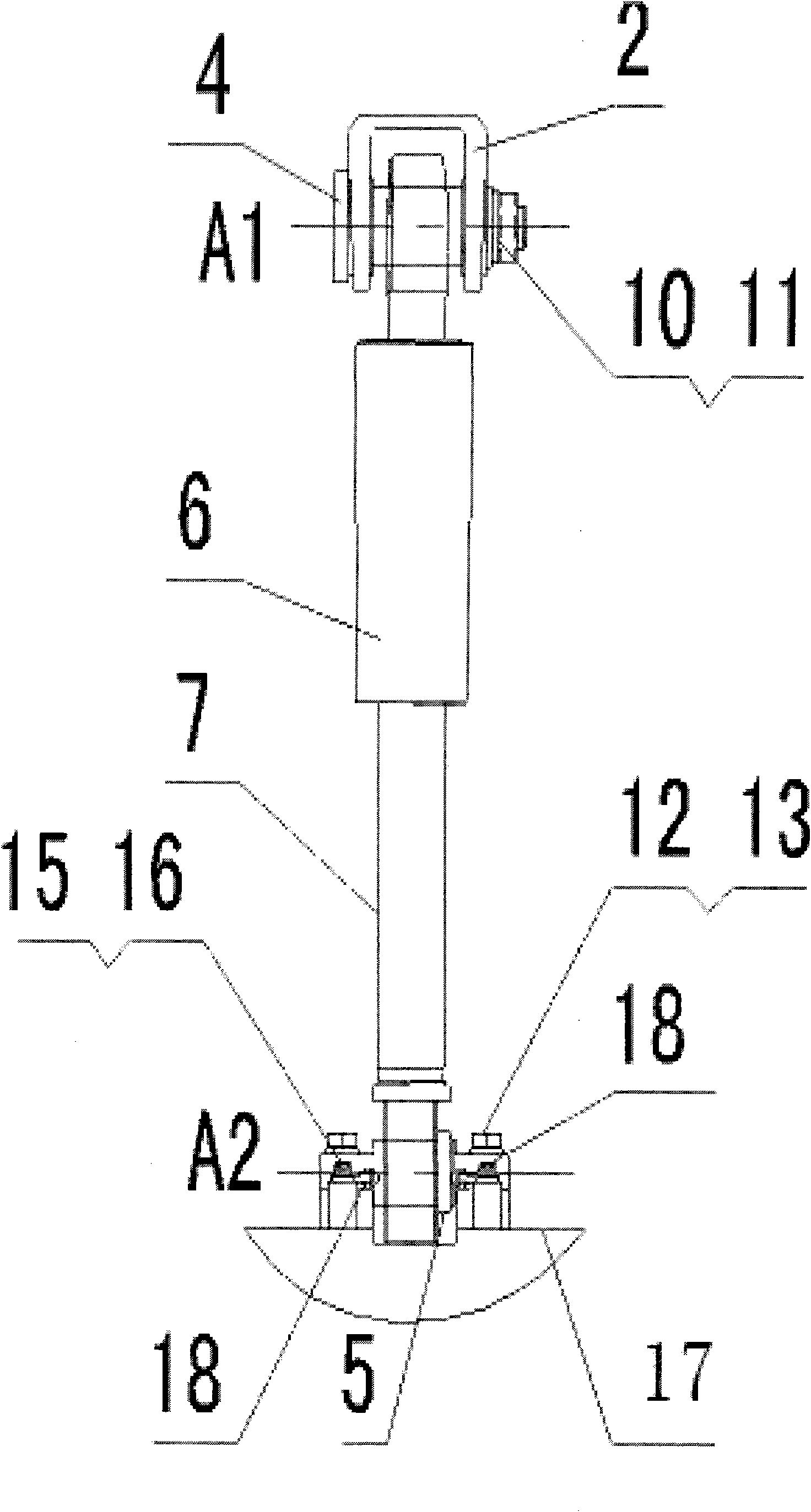

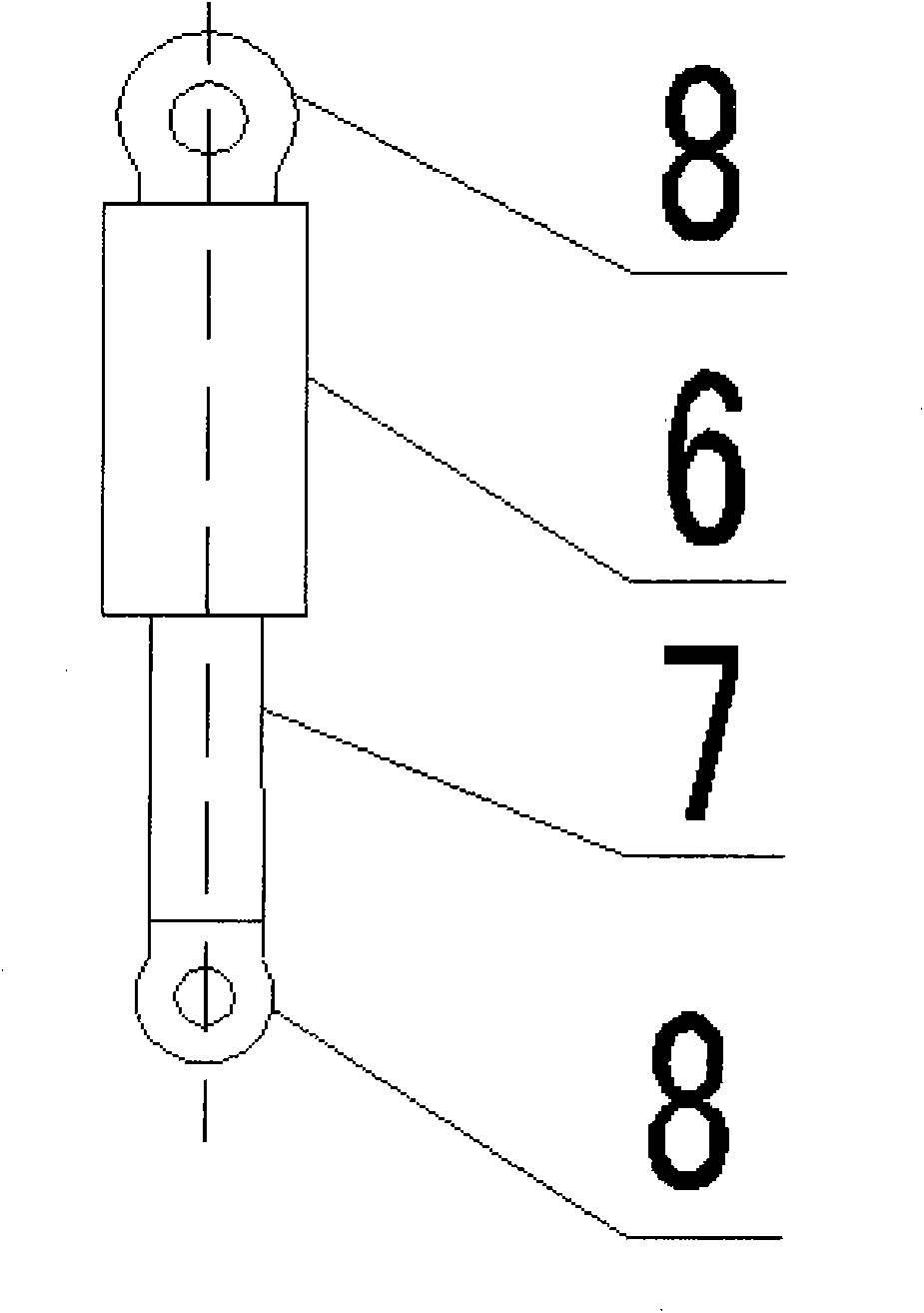

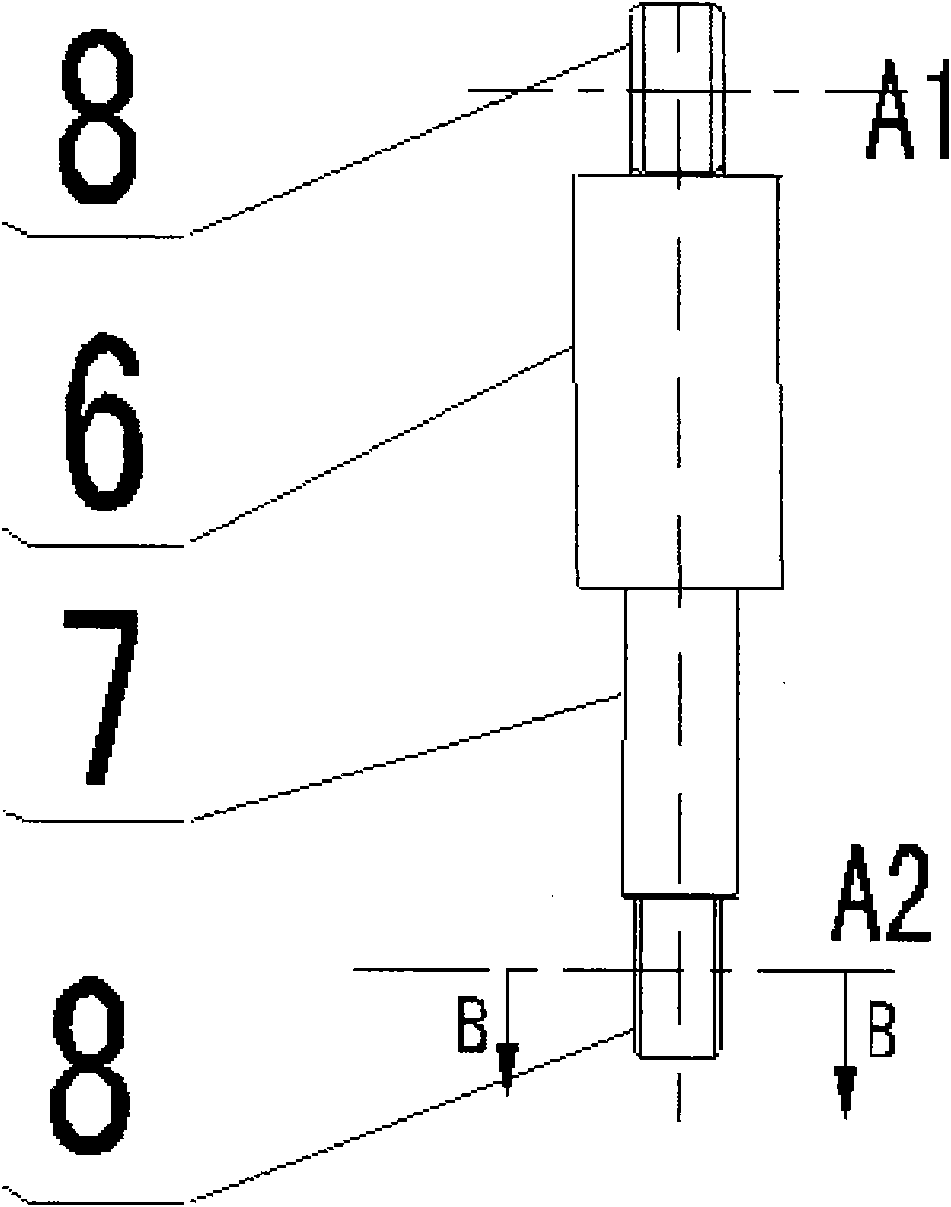

[0032] Such as Figure 1-11 As shown, a device for preventing the oil-pneumatic spring from swinging according to the present example includes an oil-pneumatic spring 3, a cross arm and a mount Q1 on the cross arm. Between the cross arm and the car body 24, to support the weight of the car body 24 and play a damping effect, the upper cross arm, the lower cross arm, the oil-pneumatic spring 3, the wheel hub assembly 14 and the car body 24 constitute a four-bar mechanism. The wheel 9 provides guidance and supports the car body 24; the cross arm includes an upper cross arm 19 and a lower cross arm 17, and the lower cross arm 17 is provided with a mounting seat Q1; there are mounting rings 8 at both ends of the oil and gas spring 3, and the oil and gas The mounting ring 8 at one end of the spring 3 is hinged on the lower cross arm 17 through the lower mounting pin shaft 5, which is actually hinged on the mounting seat Q1, and the lower mounting pin shaft 5 is fixed on the lower cr...

Embodiment 2

[0041] Such as Figure 1-11 As shown, a kind of anti-oil-pneumatic spring swinging device of the present invention, its structure is basically the same as that of Embodiment 1, the difference is:

[0042] In this example, the upper attached seat 2 is provided with an anti-swing ejector mounting seat Q2, and the anti-swing ejector rod installation seat Q2 is provided with an anti-swing ejector rod 18. The centerlines of 8 are parallel, the axes of the anti-sway push rods 18 on both sides of the installation ring 8 are coincident, and the apexes of the anti-sway push rods 18 on both sides are abutted on the end face of the installation ring 8. The distance equals the height of the mounting ring 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com